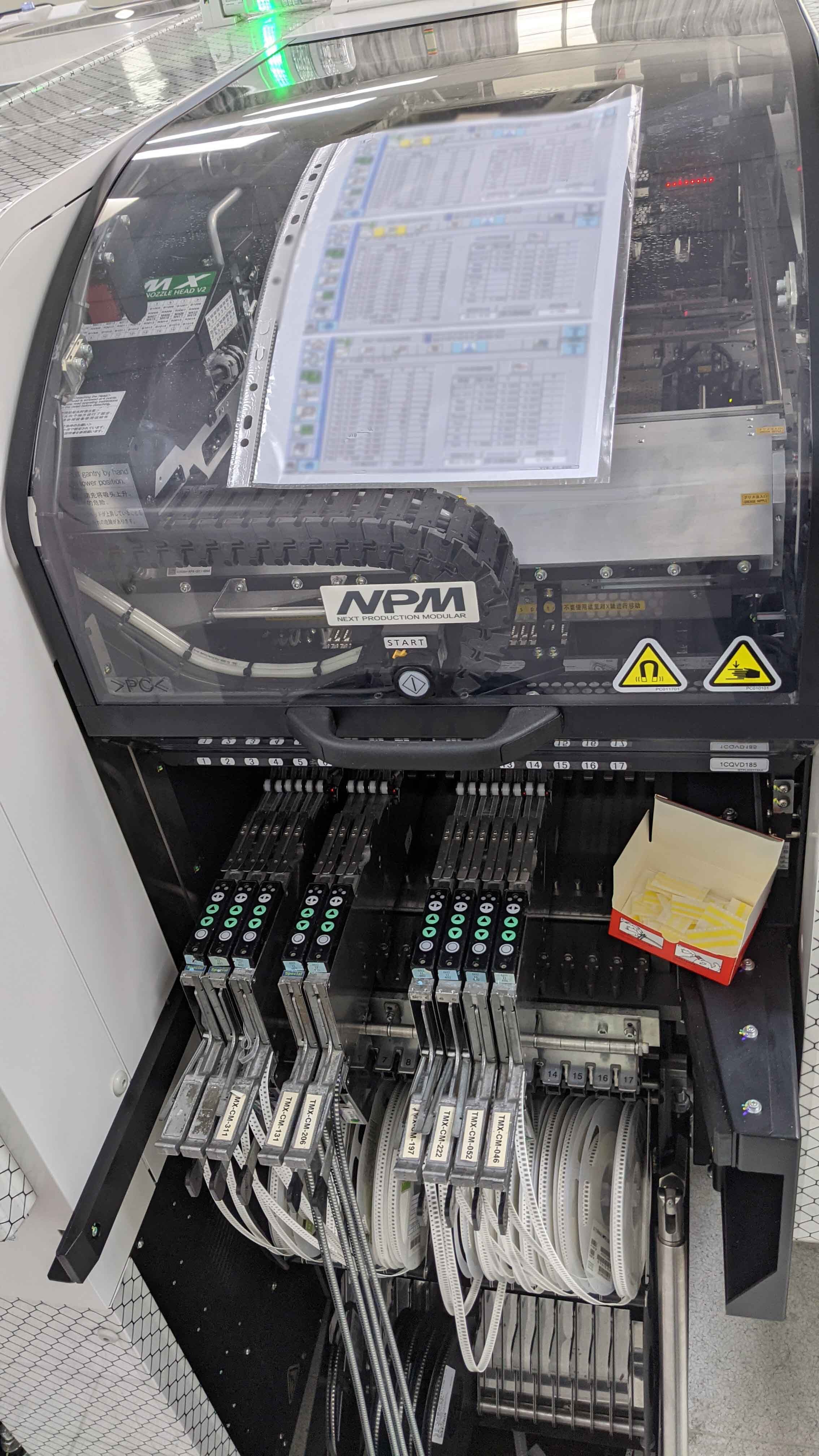

Used PANASONIC NPM-D3 #9375605 for sale

URL successfully copied!

Tap to zoom

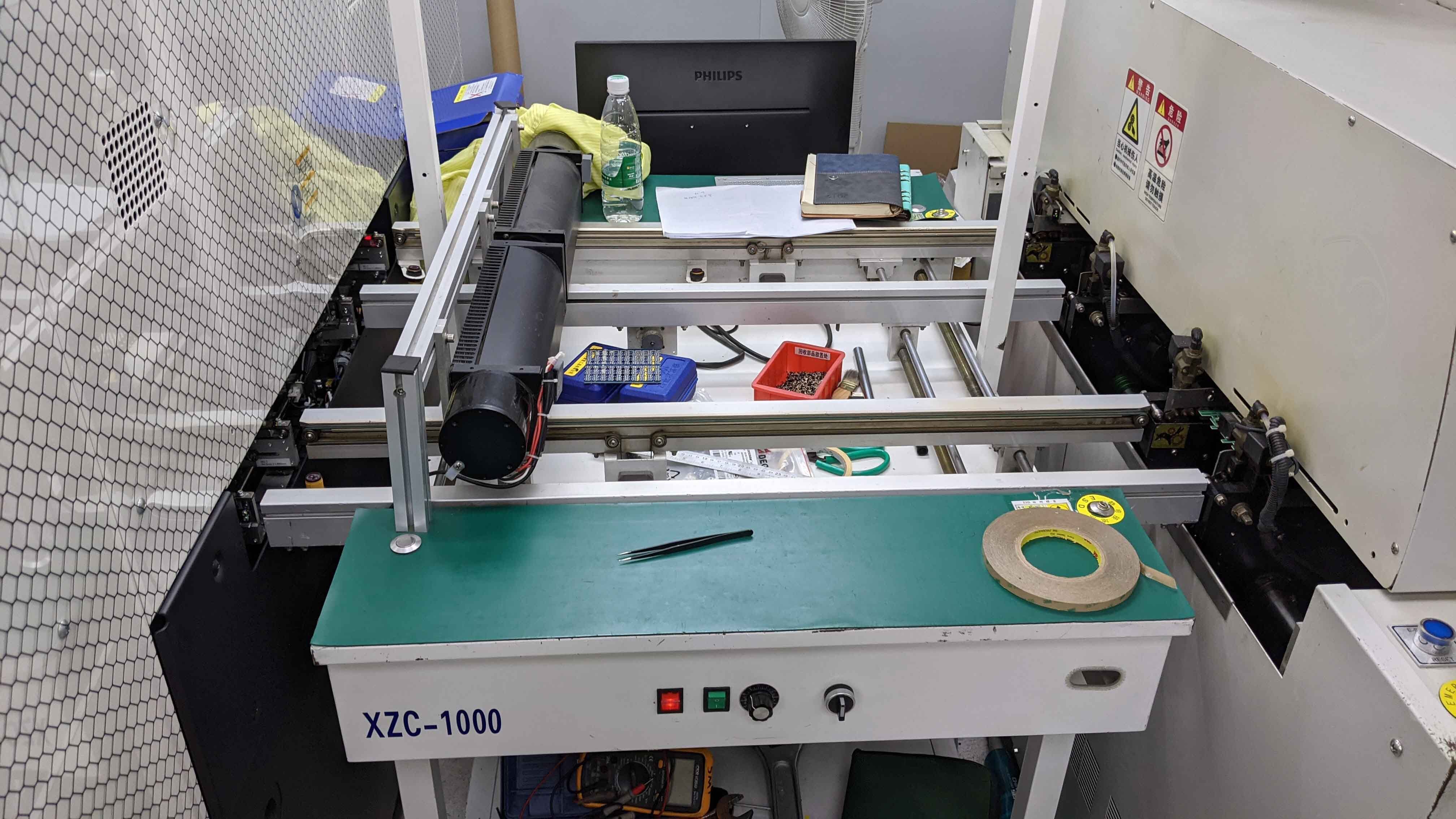

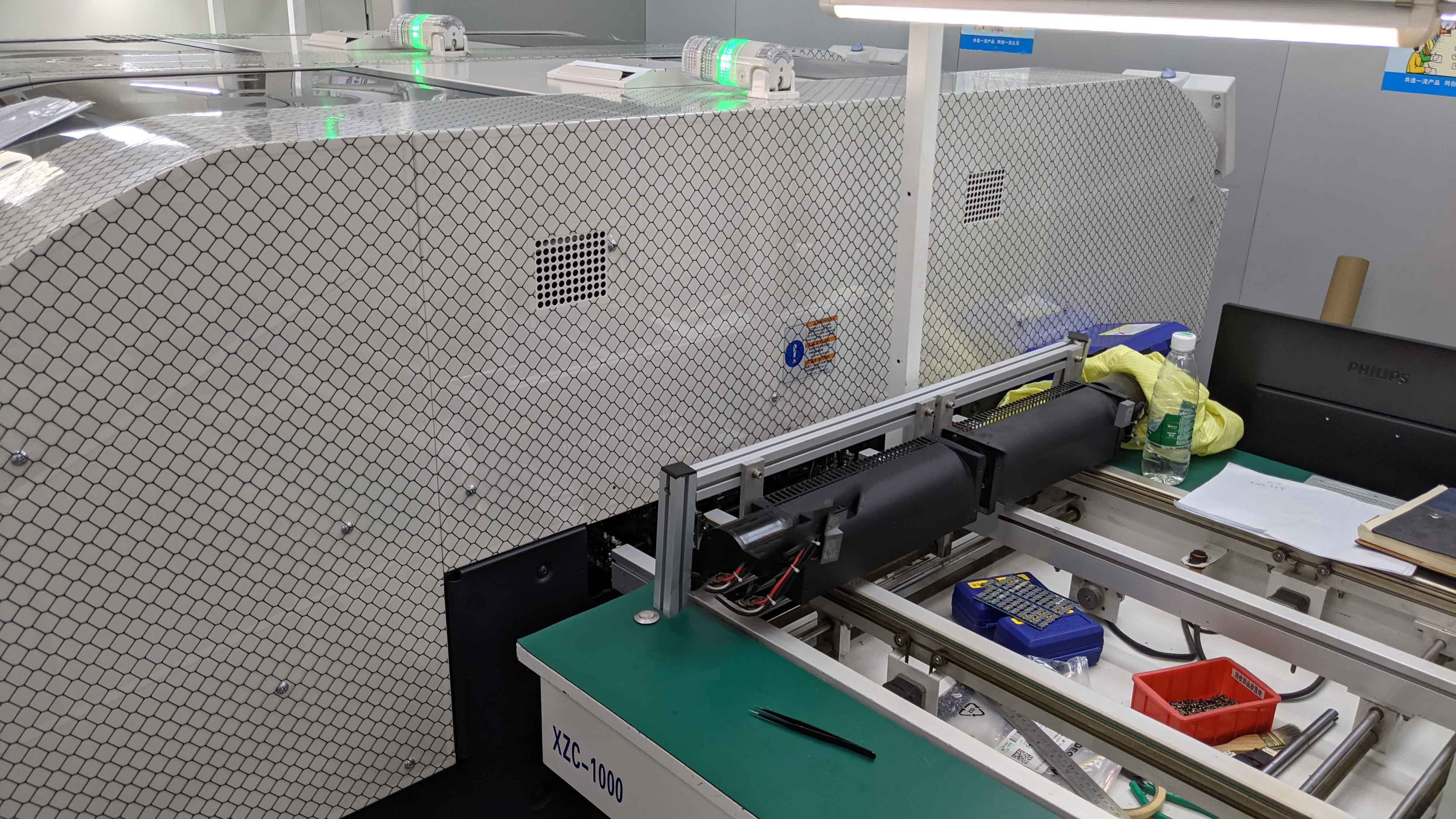

PANASONIC NPM-D3 is a high speed, large capacity, and flexible PC board assembly and manufacturing equipment. Designed by PANASONIC for medium to high volume production, it is equipped with a wide range of advanced features and is fully scalable. The system can accommodate varying types and sizes of boards and components. It also supports multiple configurations to meet changing production requirements. PANASONIC NPM D 3 supports a variety of assembly processes, including wave soldering, reflow soldering, and selective soldering. The wave soldering process is designed to enable high production speeds and delivers consistent results regardless of board size. Reflow soldering is capable of soldering large surfaces and enables precise temperature control. The selective soldering process is ideal for soldering small, delicate components, such as ICs and connectors. NPM-D3 also comes with enhanced traceability features designed to provide reliable results. It is equipped with a standard barcode reader and an optional fingerprint reader, both of which are used to acquire identifier information from PCBs and their components. This information is stored in a central memory and can be used for tracking minor changes in components used during production. The unit is also programmed to maintain a content trace of defects and rework activities. Other features common to NPM D 3 include an automated fiducial camera machine, vacuum nozzles for accurate placement of components, auto-dispensing for mixed components, and an auto-teaching tool that accelerates programming validation. Additionally, PANASONIC NPM-D3 is capable of easily switching between multiple board and component types, making the asset suitable for quick lot-change overs. With its robust design and efficient production processes, PANASONIC NPM D 3 is an excellent resource for medium to high-volume production.

There are no reviews yet