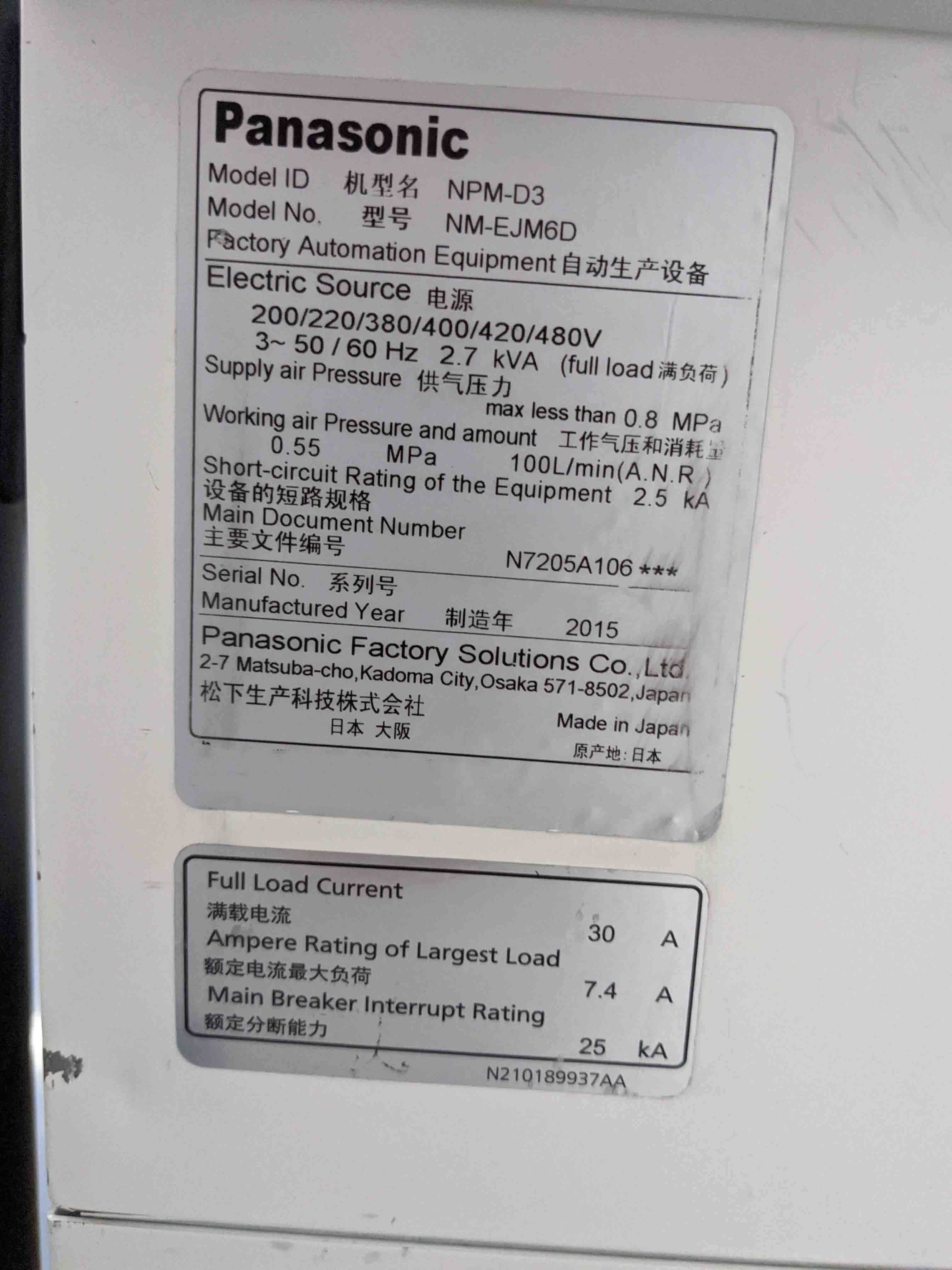

Used PANASONIC NPM-D3 #9381731 for sale

URL successfully copied!

Tap to zoom

ID: 9381731

Vintage: 2015

Pick and place machine

Model no: NM-EJM6D

H8 Head

H2

Tray

2015 vintage.

PANASONIC NPM-D3 is a PC board assembly and manufacturing equipment designed by PANASONIC to meet the needs of modern factories. PANASONIC NPM D 3 system offers a wide range of options from unique, single-part to complex multi-part systems with a maximum board size of 406 x 305 mm and is capable of handling components from 01005 to 35 mm. The unit's high-speed motion feature enables multiple device mounting from 0.2-1.2 seconds. NPM-D3 also comes with a wide selection of feeders, from simple spring-loaded types to the more specialized and flexible type, for less frequent or irregularly-shaped components such as LEDs and capacitors. The easy-to-use machine can be accessed through a touchscreen with an intuitive graphical user interface, making operation, maintenance, and troubleshooting easy. NPM D 3's multi-zone process allows for the simultaneous placement of components on both sides of the board, reducing the need for manual handling, which reduces potential damage to components. It also reduces surface contamination and defects. PANASONIC NPM-D3's high-speed placement head is capable of placing up to 8,000 parts per minute, giving users a fast and accurate solution for quickly mounting components onto boards. The tool's vision alignment is designed to offer detection capabilities for accurate placement of components without the need for additional calibration. Furthermore, PANASONIC NPM D 3 comes with two N2 nozzles for the fast and accurate placement of paste, enabling users to quickly and efficiently deposit paste for multiple functions. NPM-D3 also comes with multiple automated quality-testing features such as placement accuracy detection, powered flyway testing, and simulation testing, allowing users to quickly detect errors and reduce time-to-market. NPM D 3 is compatible with other systems, enabling users to connect multiple machines and share processes, increasing device throughput and production efficiency. Additionally, the asset comes with built-in software tools such as Auto Panelizer and Auto Merge Correction, which provide users with the ability to quickly optimize board layout and detect inaccuracies in component placement in the early stages of the assembly process, ensuring correct assembly and improving product quality. In summary, PANASONIC NPM-D3 is a powerful and versatile PC board assembly and manufacturing model designed to accommodate the needs of modern factories. Its wide selection of feeders, high-speed motion feature, and intuitive graphical user interface make it an ideal solution for quickly and accurately assembly components onto boards. Furthermore, its suite of automated quality-testing features and built-in software tools give users a fast, accurate, and reliable solution for optimizing board layout, detecting errors, and ensuring correct assembly.

There are no reviews yet