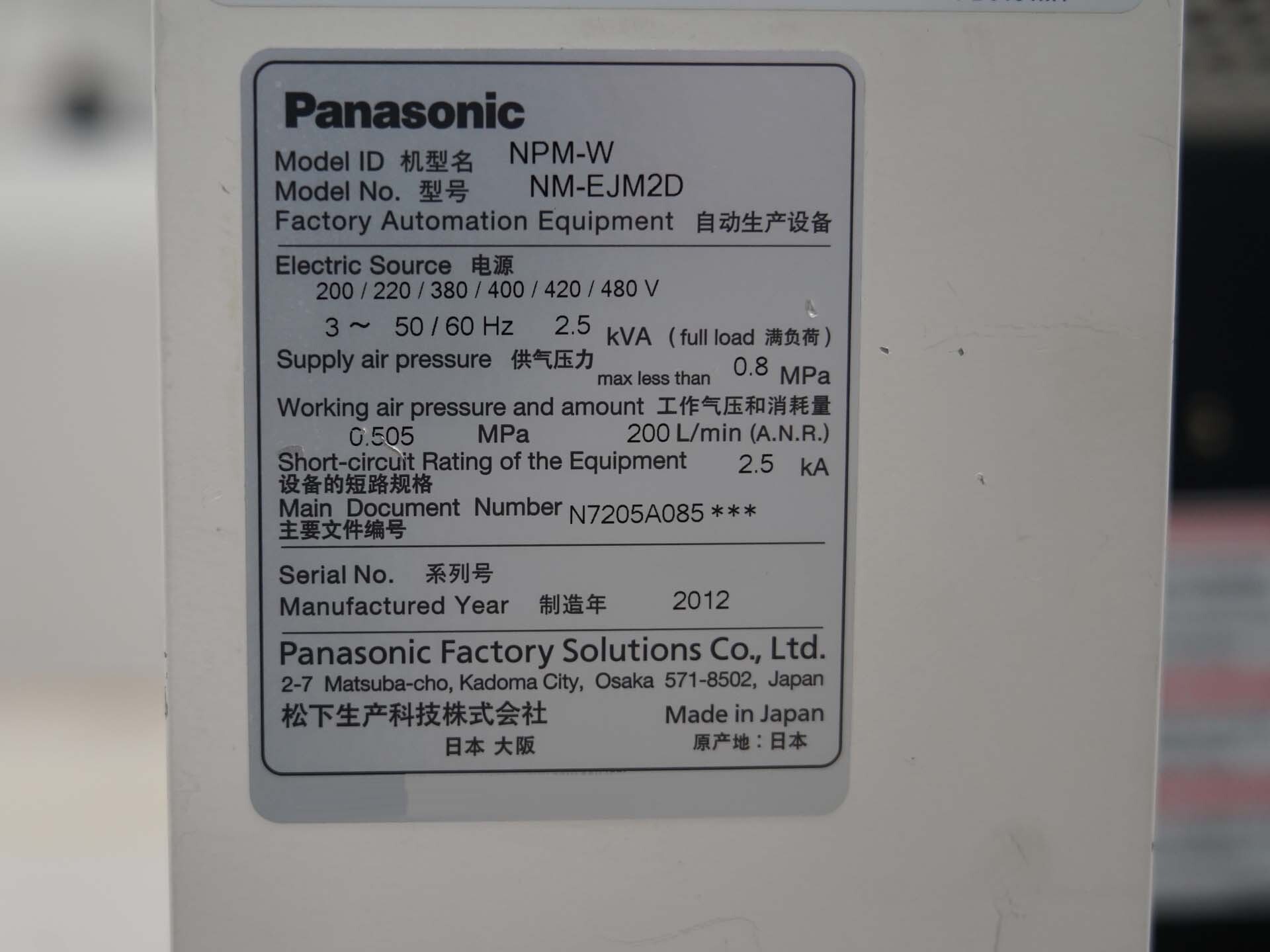

Used PANASONIC NPM-W #293592325 for sale

URL successfully copied!

Tap to zoom

ID: 293592325

Vintage: 2012

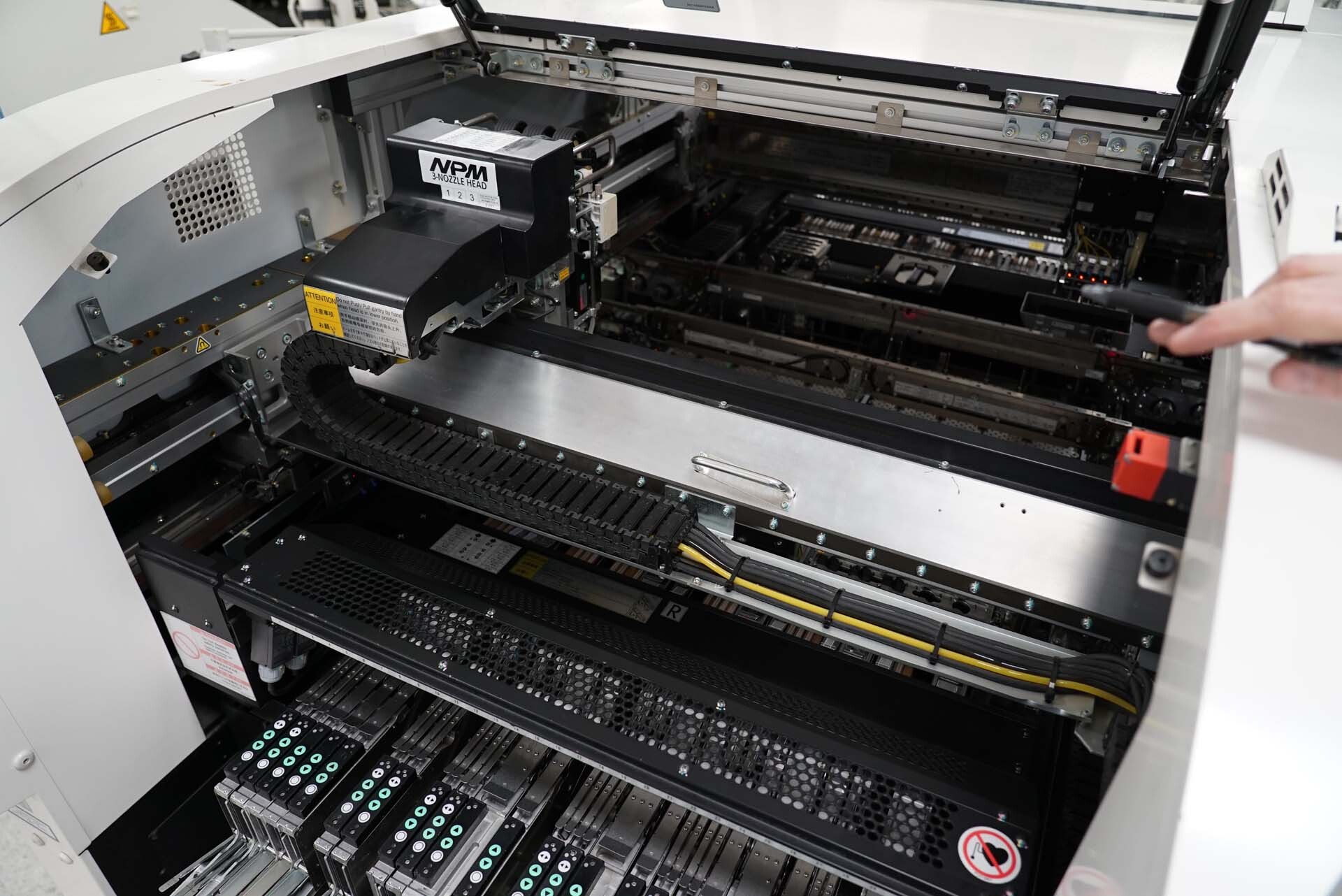

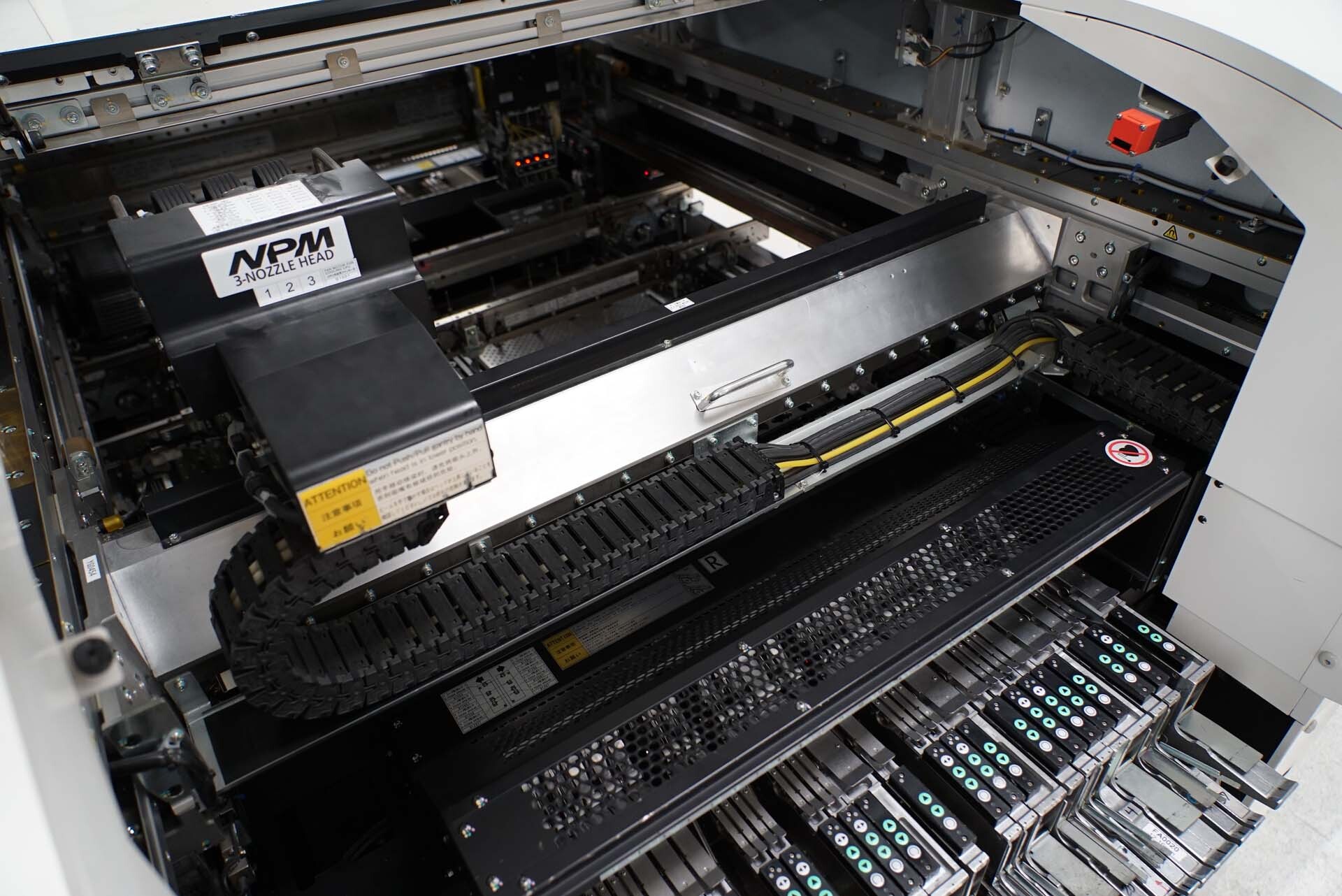

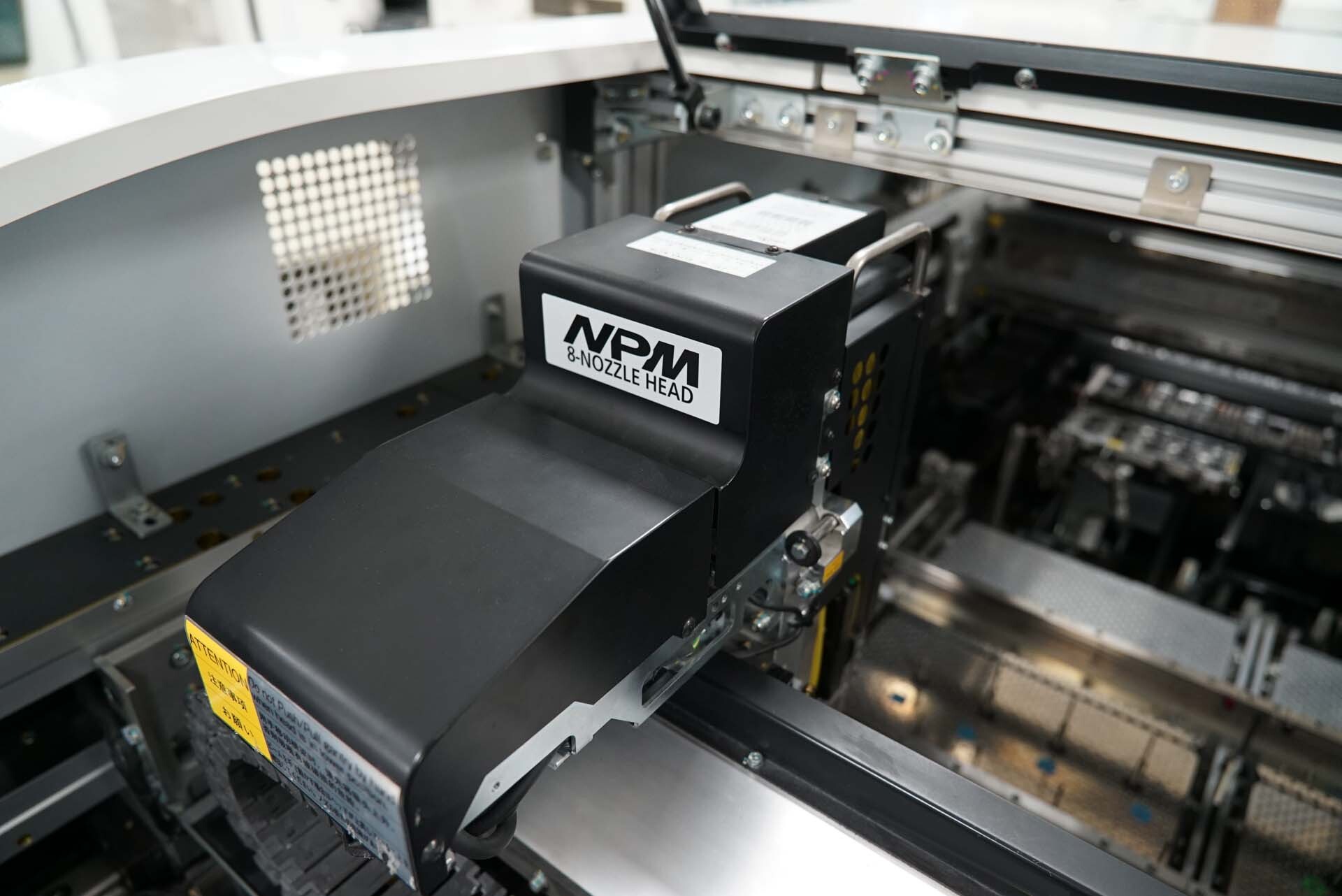

Pick and placement machine

Model no: NM-EJM2D

Stage A: 8" x 3"

(2) Modules

2012 vintage.

PANASONIC NPM-W is a state-of-the-art production equipment designed for PC board assembly and manufacturing. It consists of a fully-automated production line that features a combination of optical, physical, and electronic components that help optimize the production process. NPM-W board assembly line offers high-speed, high-precision, and high-reliability production, with the capability to complete assembly processes of up to 6.6 million parts per hour. The system features advanced pattern recognition technology and advanced robotic arm control, allowing it to perform fast and accurate production processes. Additionally, its User-Friendly Interface (UFI) makes this production line easy to operate and manage. PANASONIC NPM-W unit consists of an MOUNT Unit, INTERLINK Unit, STACKER Unit, and a POWER SUPPLY Unit. The MOUNT Unit is responsible for mounting PCBs onto NPM-W conveyor and is equipped with a Pick & Place head, which is capable of transporting up to 16 feeders at once, with a maximum feeder size of 500mm by 498mm. The INTERLINK Unit is responsible for moving PC boards across the entire line and is equipped with a robot arm that is capable of handling up to three PCBs at once, in addition to handling other tasks such as auto-screening, auto-detection, and part identification. The STACKER Unit is responsible for stacking up the mounted PCBs. The POWER SUPPLY Unit is responsible for powering PANASONIC NPM-W line and is equipped with an 800W power supply. Furthermore, NPM-W machine is equipped with several safety features, such as an emergency stop button and multiple levels of protection to guard against unexpected damage or operation errors. The tool also includes an optional feature for remote monitoring, which allows the user to track production data and troubleshoot any problems in real time. Overall, PANASONIC NPM-W is an advanced board assembly and manufacturing production asset that offers high-speed, high-precision, and high-reliability production. The model is easy to operate and maintain and has several advanced features, such as its pattern recognition technology, ROBOT Arm control, 800W power supply, and remote monitoring capability. This equipment is well-suited for tackling most types of production processes and makes it easier and more efficient for businesses to manufacture PC boards.

There are no reviews yet