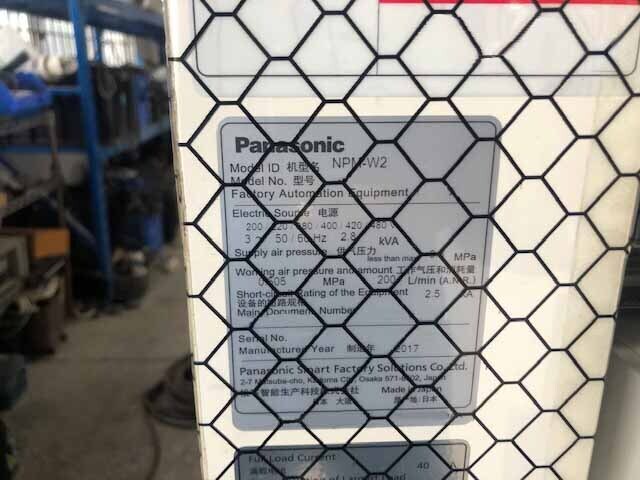

Used PANASONIC NPM-W2 #9280199 for sale

URL successfully copied!

Tap to zoom

ID: 9280199

Vintage: 2017

Placement machine

Head 16+16

(2) Feeder carts

Does not include tray

2017 vintage.

PANASONIC NPM-W2 is a high-speed, multi-functional platform for automated assembly and manufacturing of printed circuit boards (PCBs). This equipment is designed to provide a highly efficient production flow for both conventional and high-density PCBs. The system features a scalable design with a broad range of models offering different levels of board size, thickness and speed to meet almost any production requirement. NPM-W2 unit is equipped with up to 4 independently programmable feeders per machine, with a maximum number of 52 for the higher-end models. The placement head is compatible with almost all component types, including 01005 size parts, making the machine flexible enough to handle a wide range of components. The placement head also features a vision tool for flexible mounting of components, enabling it to recognise different types and orientations of components. The high-speed motion control asset offers up to 132 placement heads with a maximum of 8 pick and place heads per machine. This high-speed machine offers up to 99% placement accuracy, thanks to its advanced precise motion control technology. Furthermore, this model is equipped with a 0.2 second alignment time for more efficient component mounting. The user-friendly design of the equipment enhances the ergonomics of the operation, enabling simpler process set-up and enabling convenient access to various settings and machine options. Additionally, the system also stores data for up to 100 different jobs, making it easy to recall presets. TheNPM-W2 offers an impressive placement rate of 50,000CPH, making it faster than ever to get the boards to market. The unit is backed by advanced and comprehensive software, which provides a total production solution for PCBs. This software includes support for component alignment, auto-placement, process monitoring, data reporting and inventory. Additionally, the machine also includes an innovative machine monitoring and debugging tool, which allows for optimized processes and total board quality management. PANASONIC NPM-W2 is one of the most advanced systems for automated assembly and manufacturing of printed circuit boards available on the market. This asset offers unparalleled speed and accuracy, making it the perfect choice for high-volume production. Furthermore, the intuitive design and comprehensive software make it a must-have for any PCB assembly and manufacturing model.

There are no reviews yet