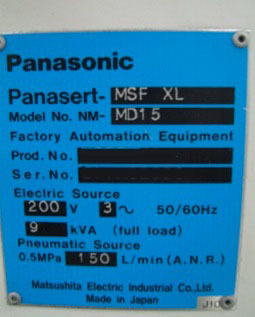

Used PANASONIC Panasert MSF-XL #9072149 for sale

URL successfully copied!

Tap to zoom

ID: 9072149

Vintage: 2003

Pick and place machines

Model No.: NM-MD15

Tray

2002 - 2003 vintages.

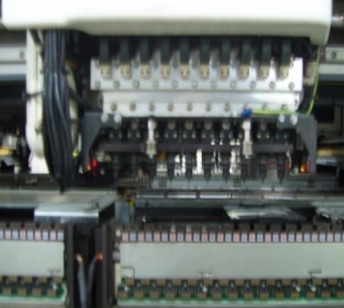

PANASONIC Panasert MSF-XL is an advanced and highly automated pc board assembly and manufacturing equipment which is beneficial for higher productivity, improved accuracy and enhanced dependability of production line jobs. The PC board assembly and manufacturing system is featured with many innovative elements such as high-performance and flexible placement head, computer-controlled precision blowing unit and tri-level lead frame feeder machine. The high performance and flexible placement head is equipped with servo motor based driving force on each axis, allowing for both high-speed and precise placing of components onto the pc board. It is capable of carrying out placement of components from 0201 size up to 55x55mm large BGA, and placement speed is up to 100 components/second. A built-in dual vision camera also ensures high accuracy and efficiency for placement operation. The computer-controlled precision blowing tool is also capable of providing precise fine-pitch placement with a high performance blowing nozzle. The blowing asset is able to achieve a high-precision placement of 0201 size components down to 1.2mm pitch due to its dynamic pressure control technology and Enhanced Plate Accuracy feature. The 1.2 mm pitch feature is suitable for HDI technology and the blowing technology also ensures maximum cost savings and operational efficiency. The tri-level lead frame feeder model increases the production process efficiency and minimizes the cost for lead frame components in high-mix applications. The lead frame feeder equipment is able to regulate the lead frame feed rate according to the desired specification and component density. This allows operators to cycle the lead frames more quickly and securely, thus saving time and money. Panasert MSF-XL pc board assembly and manufacturing system is a top-of-the-line machine that is designed to help with the production process with improved accuracy and better operational efficiency. It is easy to use and maintain with a user-friendly interface and does not require any setup time prior to starting operation. The machine's highly automated features make it perfect for large-scale production environments.

There are no reviews yet