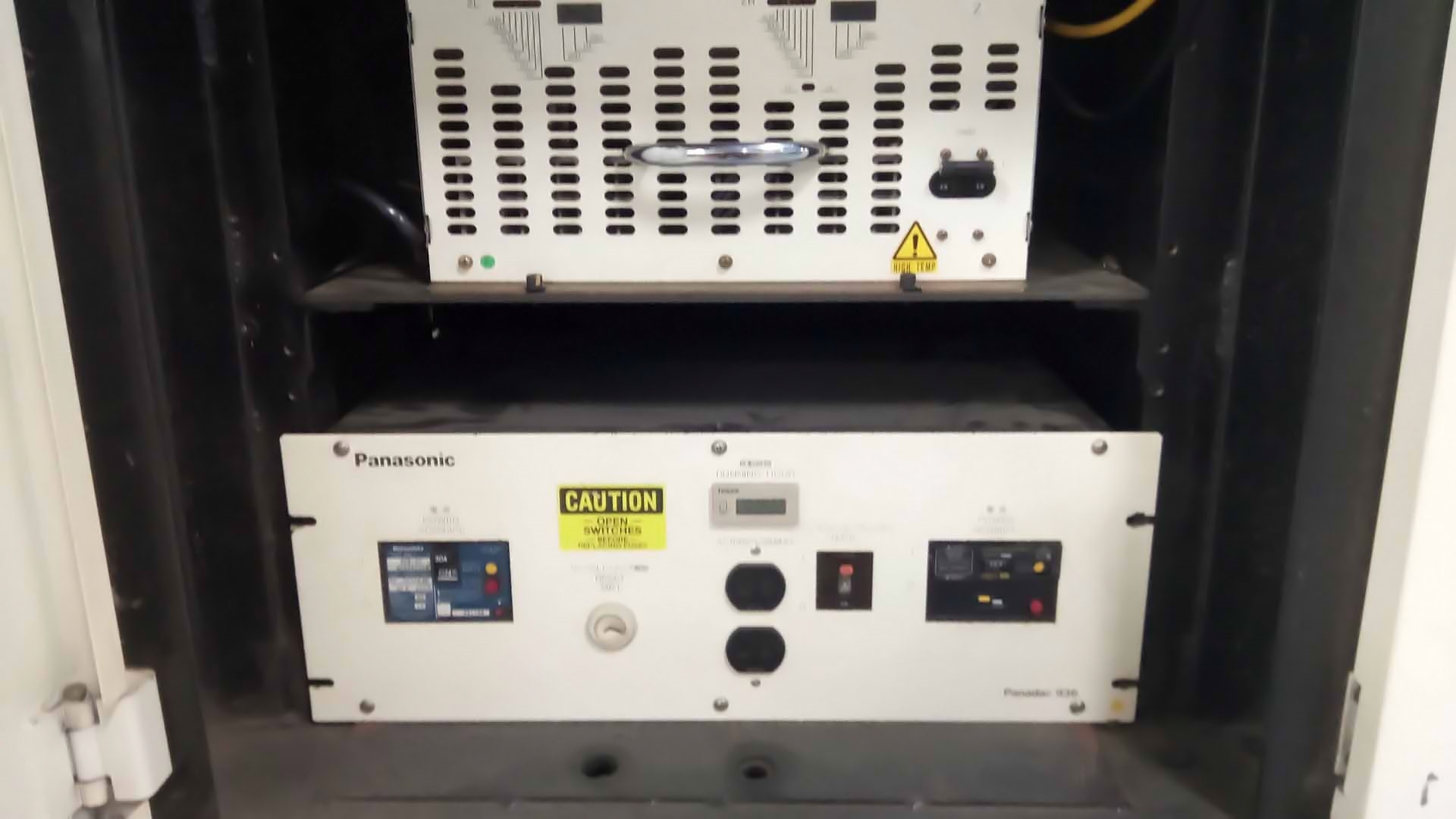

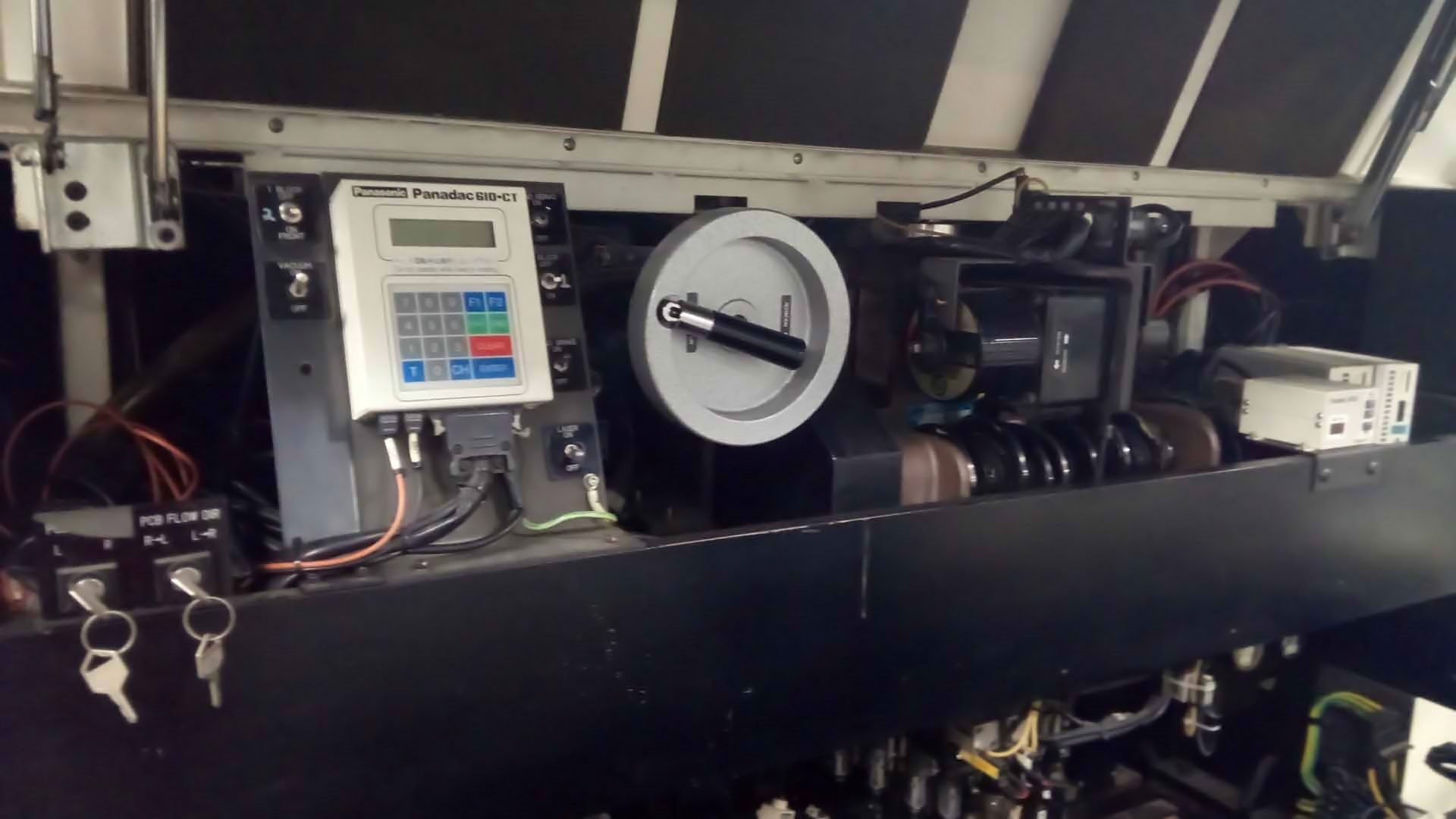

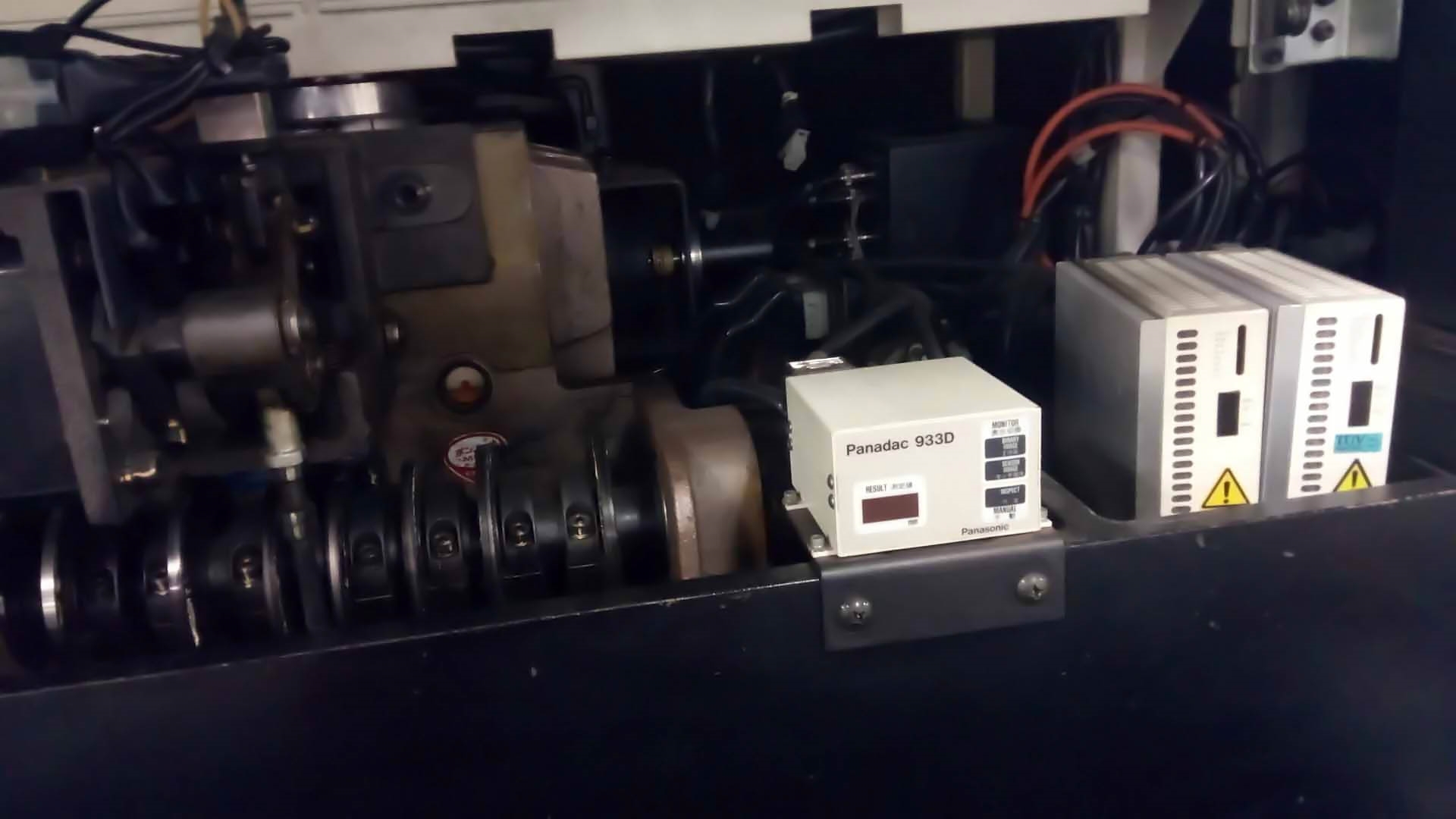

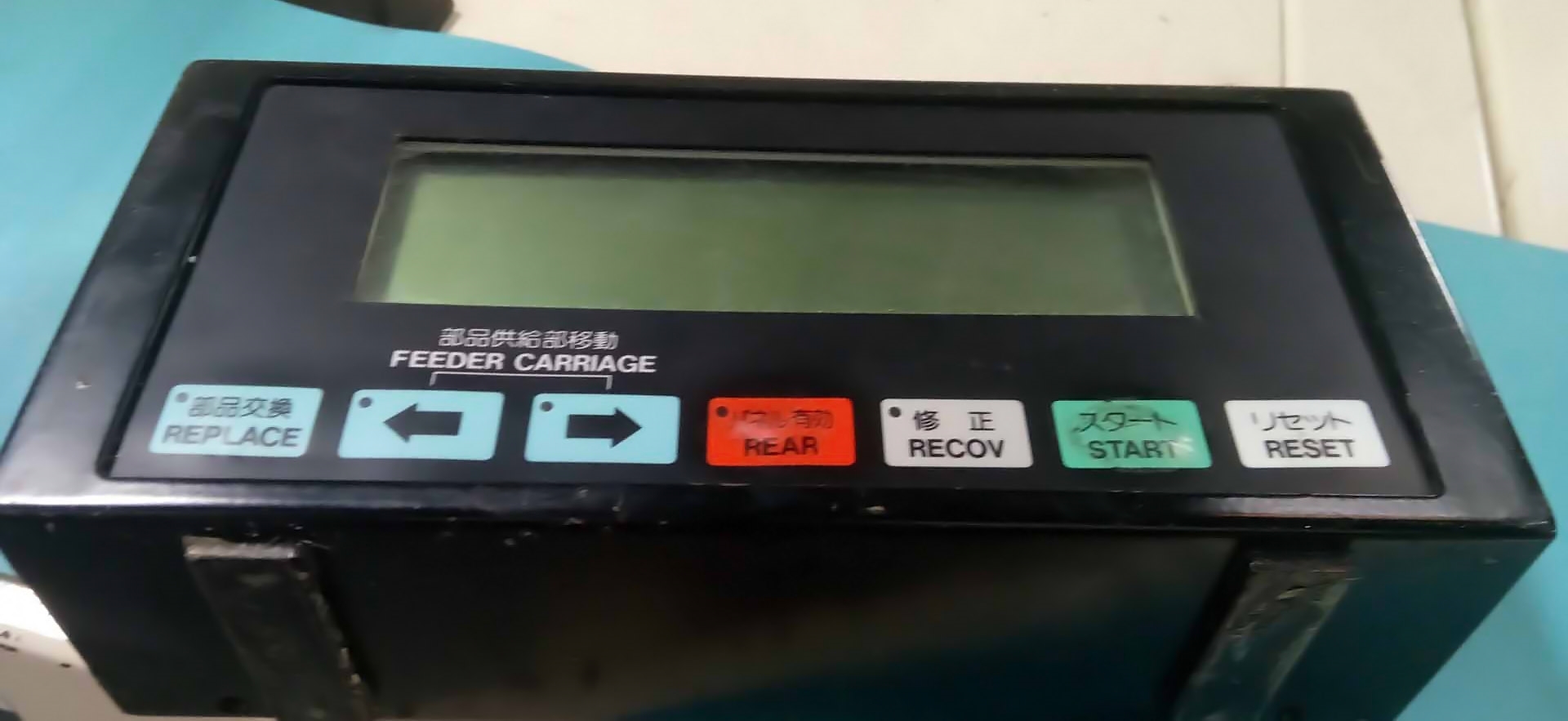

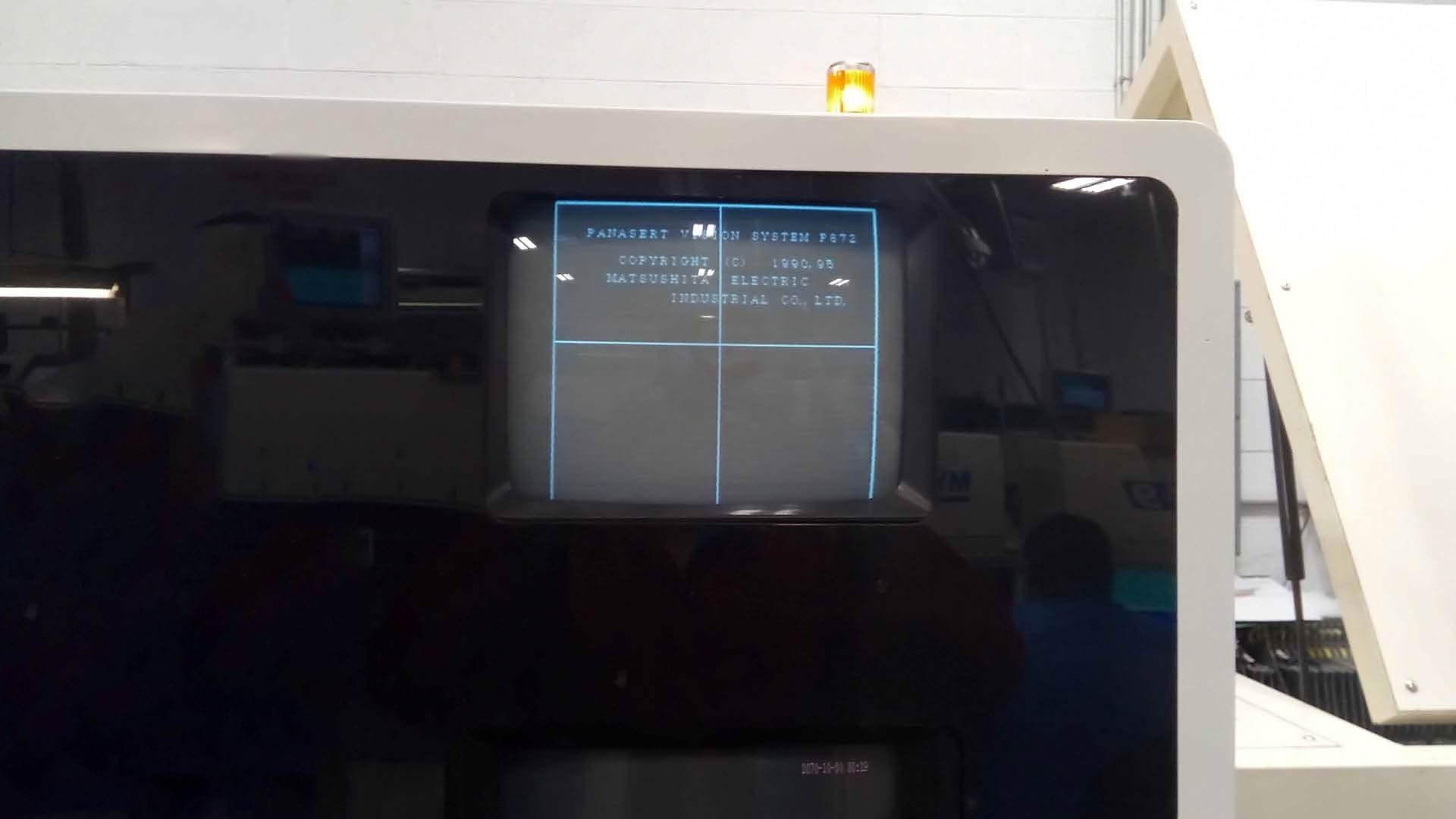

Used PANASONIC Panasert MSH-2 #9220913 for sale

URL successfully copied!

Tap to zoom

ID: 9220913

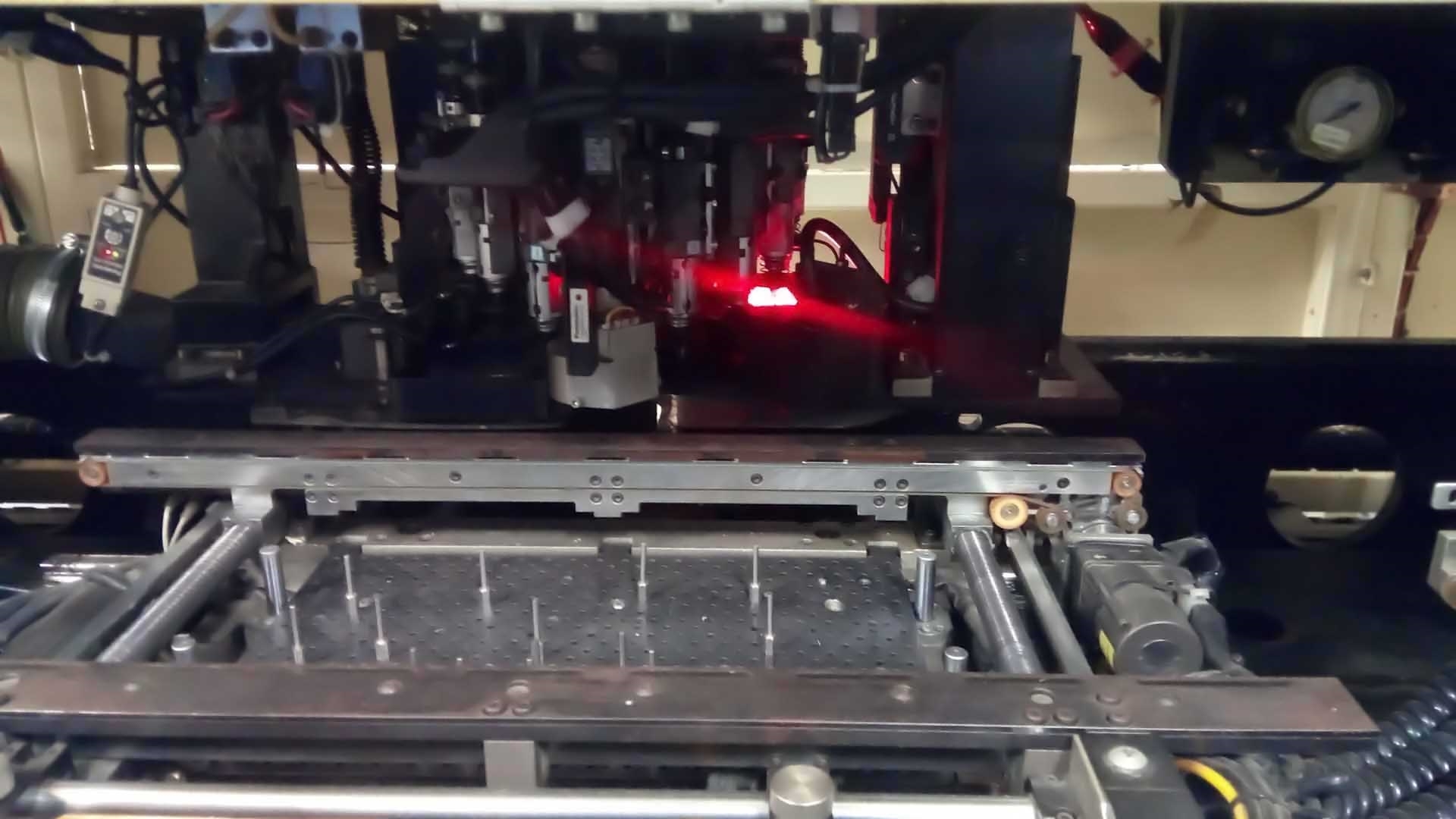

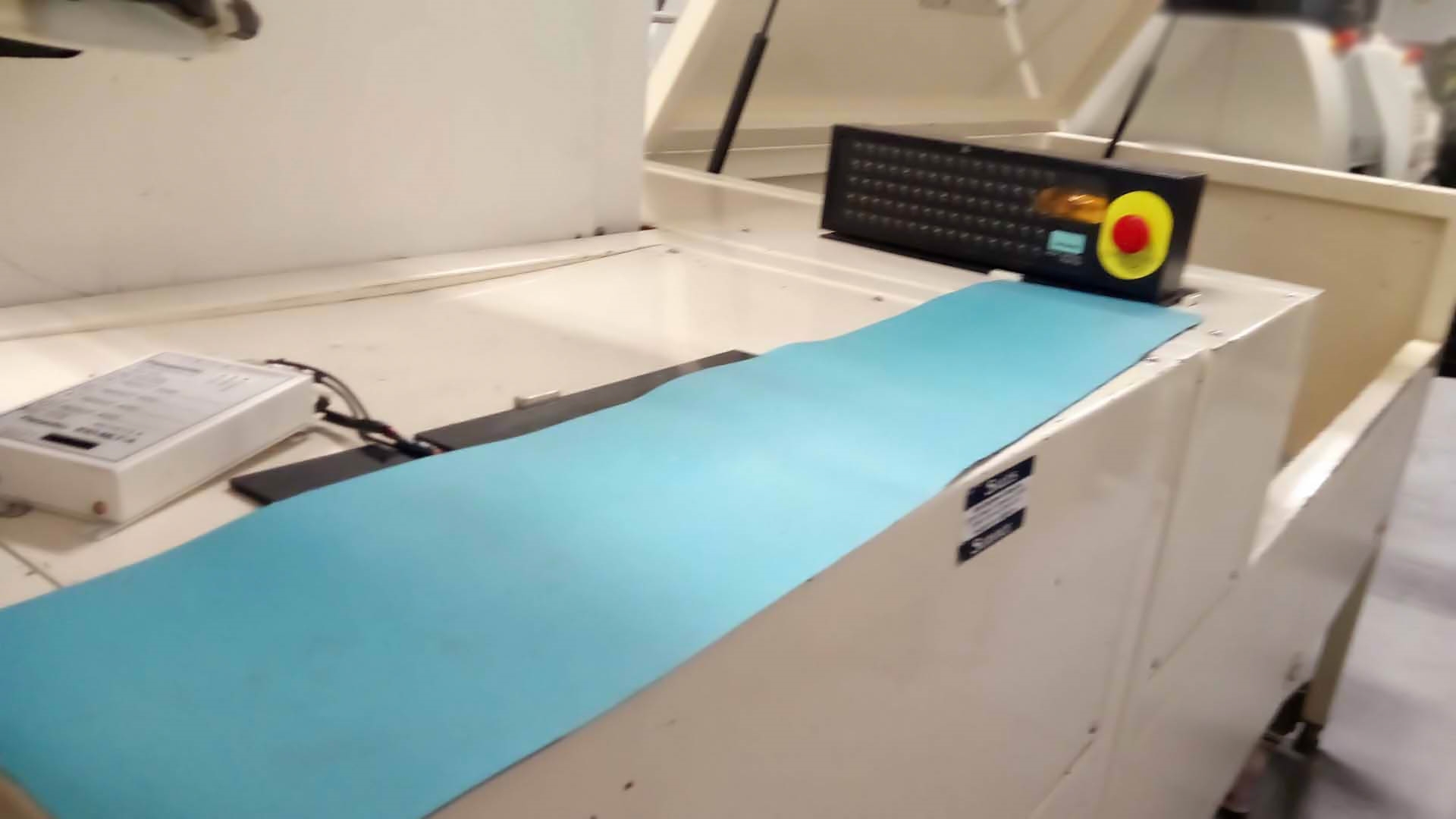

Pick and place machine

Includes:

LCS

(25) CL Feeders

Air: 0.55 mps

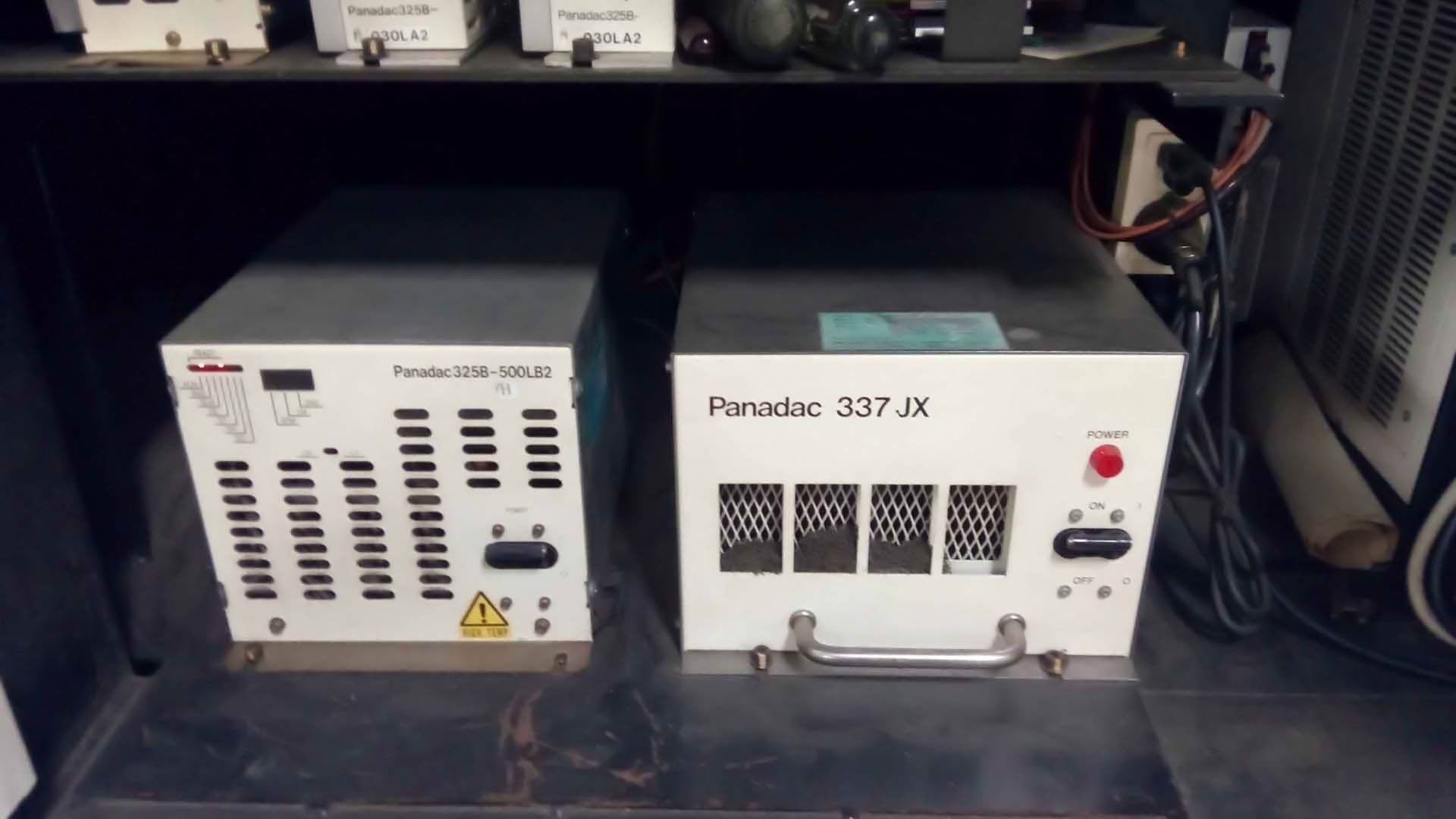

Power supply: 200/208 V, 3 Phase, AC 50/60 Hz, 4.4 kVA (Maximum).

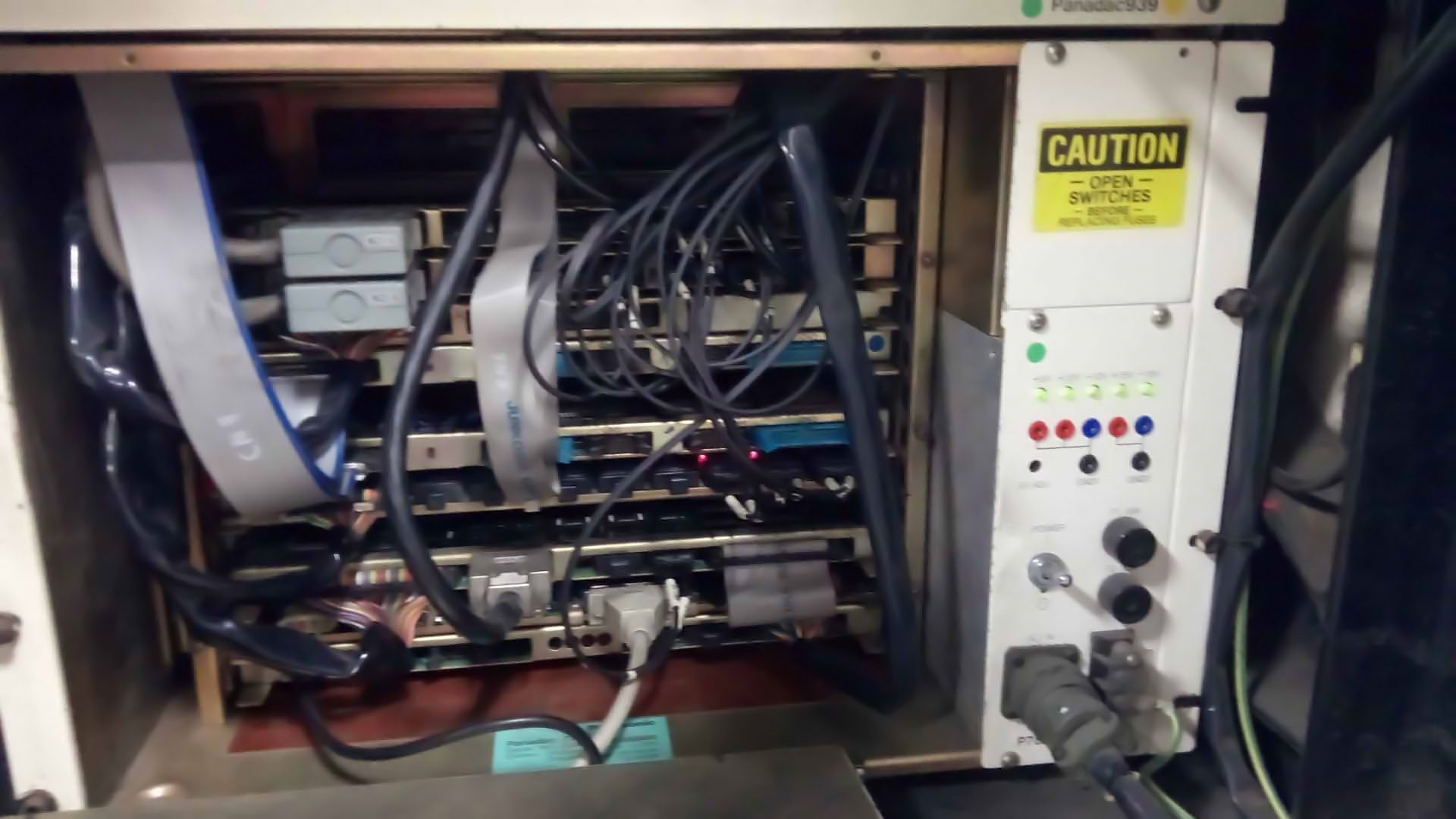

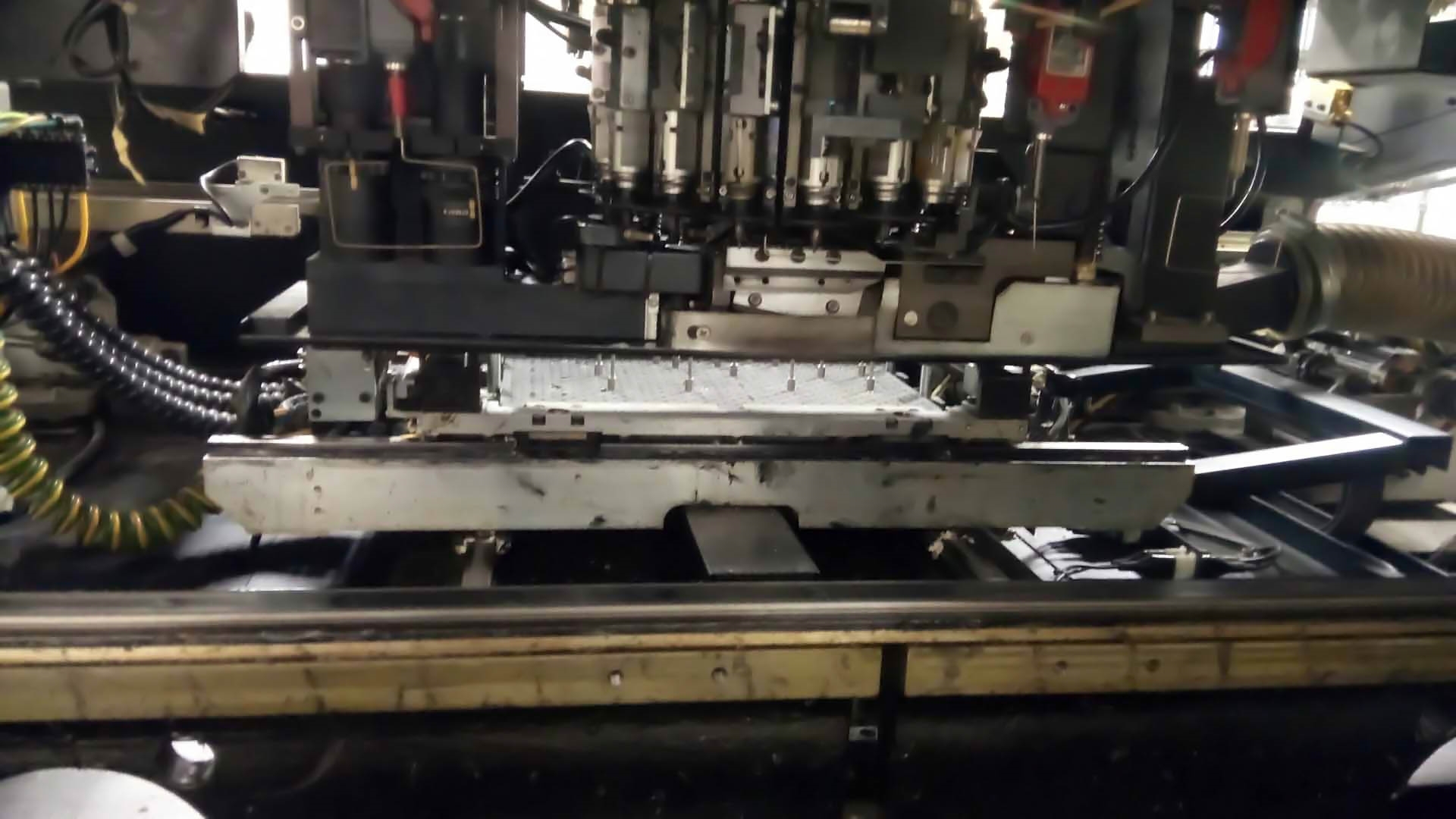

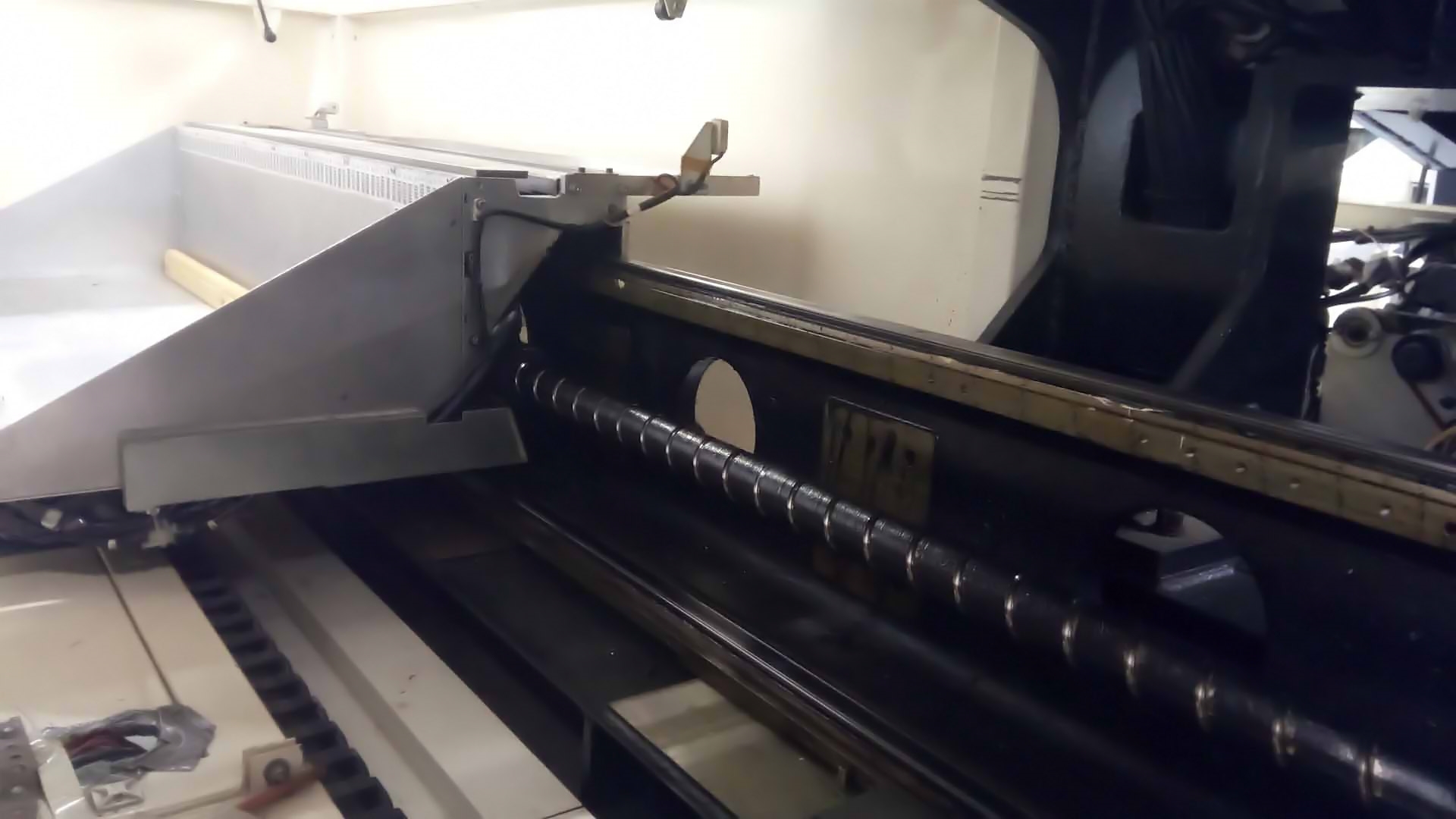

PANASONIC Panasert MSH-2 is a PC board assembly and manufacturing equipment ideal for PCB assembly and manufacturing applications. As an integrated system, it offers functions such as pick-and-place, inspection, and assembly. The MSH-2 is especially designed for small and medium-sized PCB production jobs, and to accommodate large-scale PC board assembly. This unit is equipped with an AC servo and high-speed transfer machine, which offers a precise and fast operation. It is capable of handling a wide variety of components, including BGA, LGA, and QFP, with the intelligent parts recognition feature. It also features fine-pitch components placement, including passive components, which makes it suitable for delicate PCB assembly tasks. Moreover, the MSH-2 boasts optional head rotation for true double-sided assembly, making it ideal for double-sided rigid PCB production. The MSH-2 also features an in-line advanced inspection tool which can detect short circuits and open circuits on both assembled and non-assembled boards. This asset is also capable of performing automatic opto-electronic inspections of component type, position, polarity, and soldering quality on both assembled and non-assembled boards. Additionally, it supports a wide variety of barcode scanners for non-contact traceability of parts and assemblies. Furthermore, the MSH-2 is equipped with an integrated stocker that can store up to 133 different component types, making it an ideal solution for medium to large-scale PCB production jobs. It can also be easily automated by connecting an auto loader/unloader model to reduce manual intervention and maximize throughput. To sum up, Panasert MSH-2 is an advanced integration solution for PC board assembly and manufacturing. It offers precise and fast operation, wide component capability, advanced inspection features, and integrated parts storage. These features make the MSH-2 an ideal equipment for medium to large-scale production jobs, enabling it to perform both automated and manual tasks efficiently and effectively.

There are no reviews yet