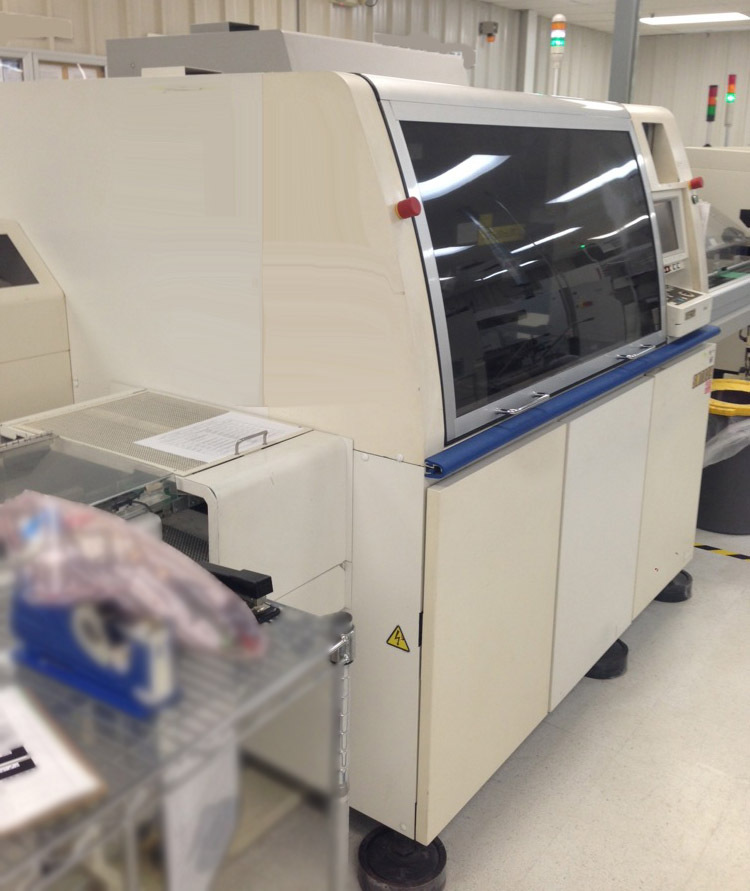

Used PANASONIC Panasert MSR-XL #9074787 for sale

URL successfully copied!

Tap to zoom

ID: 9074787

Placement machine

Model No. NM-HD15

Full Feeder Carriage Capacity: 75x75

(125) Feeders: 8mm.

PANASONIC Panasert MSR-XL is a high-tech PC board assembly and manufacturing equipment designed to offer advanced automation and flexibility in product manufacturing. The system consists of two main components: the Automatic Component Insertion (ACI) and the Mass Storage Retrieval (MSR). The ACI is responsible for the insertion of components into the motherboard for assembly, while the MSR handles the storage and retrieval of components. The unit can accommodate up to 180 different components in its storage and retrieval machine. This tool provides the flexibility to change, modify and assemble the components quickly. The asset is compatible with a variety of boards, from single-side and double-sided designs to multi-layer, surface-mount and through-hole boards. It also supports a wide variety of components, from complex leaded components to simple surface-mount device packages. The MSR-XL is also equipped with several other features such as Auto Lead Probe and Auto Lead Insertion, which allows users to reduce manual lead and chip placement errors, as well as Auto White Balance, which ensures even lighting across the entire assembly line. There is an integrated camera model that gives users the ability to inspect the PC boards throughout the assembly process, providing a reliable method for ensuring quality. Additionally, the equipment can be programmed to handle boards up to 800mm in width, allowing for faster and more exact placement of components. The MSR-XL includes several tools for optimizing the process. These include Visual Assist Technology, which gives users the ability to view assembly information in real-time and can easily be configured to fit the specific assembly needs. Workcell Vision System, which allows the unit to be used with different sizes and shapes of PC boards, and also helps detect errors before they can cause major damage to the assembly process. The machine is also designed to be efficient and durable, with a modular design that allows for quick and easy maintenance and upgrades, and a robotic arm with a long life span. The tool also offers several safety features, such as the three-step robotic arm that protects workers by quickly retracting the arm to avoid possible physical contact with components, and a sensor asset that automatically locks the arm if a problem is detected. Overall, Panasert MSR-XL is an efficient and highly reliable PC board assembly and manufacturing model. Its sophisticated robotic arm and integrated camera equipment allow for precise placement of components and accurate inspection of the finished boards, and its modular design allows for quick and easy maintenance and upgrades. With its wide range of features and tools, PANASONIC Panasert MSR-XL is the ideal system for businesses that need advanced automation and flexibility in product manufacturing.

There are no reviews yet