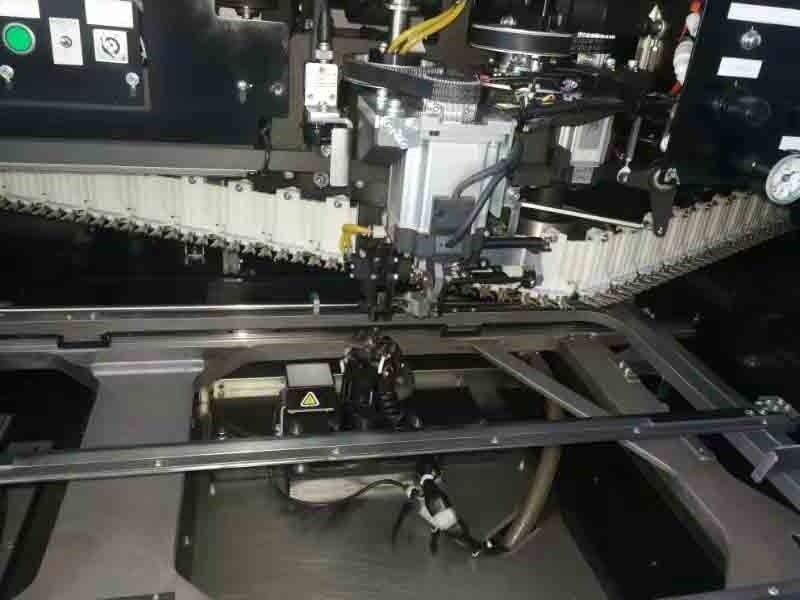

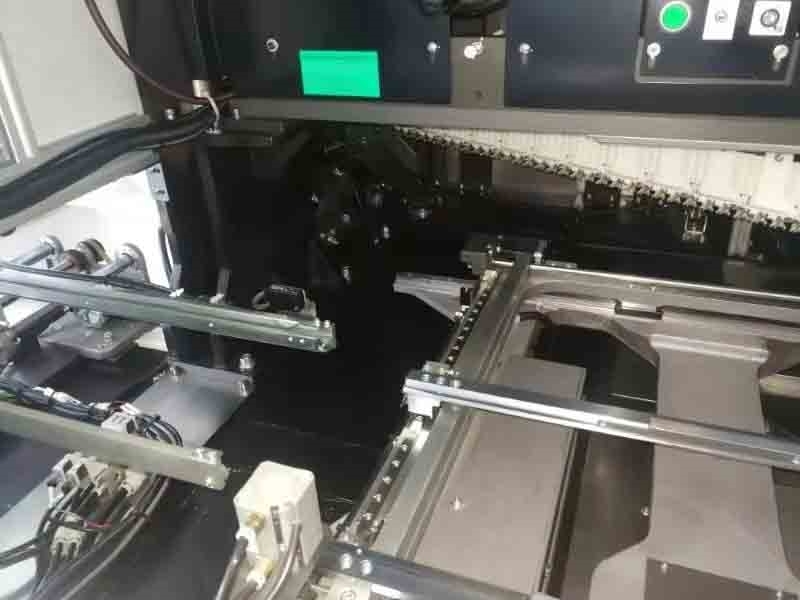

Used PANASONIC RG131 #9171421 for sale

URL successfully copied!

Tap to zoom

ID: 9171421

Vintage: 2012

Radial inserter

Model: NM-EJR3A

(3) Guide pins

(20) Cassettes

(40) Stations with (40) feeders

Tooling: 2.5 mm and 5 mm

Loader and unloader included

2012 vintage.

PANASONIC RG131 is a PC board assembly and manufacturing equipment made by PANASONIC. The system is designed to enable both significant cost savings and dramatically increased efficiency in PCB assembly and manufacturing processes. It is a robust and reliable pick and place unit that can accommodate a wide range of board sizes up to 19" x 19". The machine features a high precision, closed-loop linear motor drive, designed to provide high speed placement accuracy over its entire working area. A fiber based camera tool also allows for simultaneous "top and bottom" vision to ensure parts align correctly before being placed. Using a CAM asset, this model can read and recognize any components' shape, including through-hole components and SMD components, and can quickly adjust its place parameters accordingly. For updating component data in PANASONIC RG 131, an easy-to-use editor is available which can quickly and accurately update the parts data on a flash memory card. With this component library, the machine can quickly adjust its placement parameters as new components are added. In addition, it has a Multi-Block equipment which can handle several block/positioner at the same time, helping multiple pick and place jobs run at the same time which speeds up the machine's efficiency and throughput. RG131 system also has additional features such as a complete range of vision and inspection tools, 3D capability, assembly verification and machine to machine data communication. A wide selection of board support fixtures, vision lighting and carrier feeders are available to customize the unit for specific board assembly jobs, enabling efficient placement of both through-hole components and surface mount devices. In conclusion, RG 131 PC board assembly and manufacturing machine provides a fast and efficient way to accurately assemble boards. Its closed-loop motor drive ensures consistent placement accuracy, while its vision technology ensures precise alignment of parts. Its simple interface and easy component library updating further make it a great solution for PCB assembly and manufacturing.

There are no reviews yet