Used PANASONIC RG131 #9249707 for sale

URL successfully copied!

Tap to zoom

ID: 9249707

Vintage: 2011

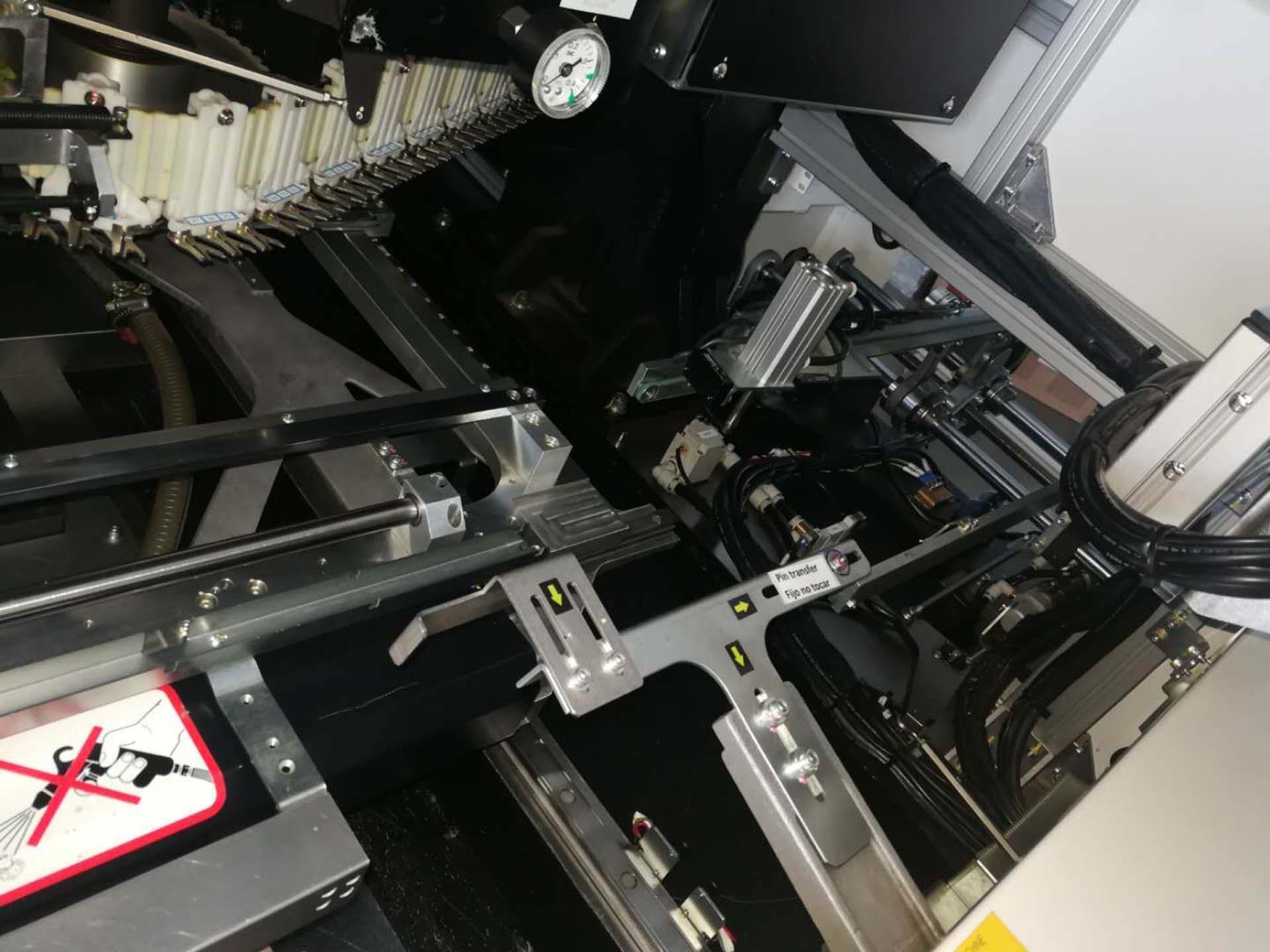

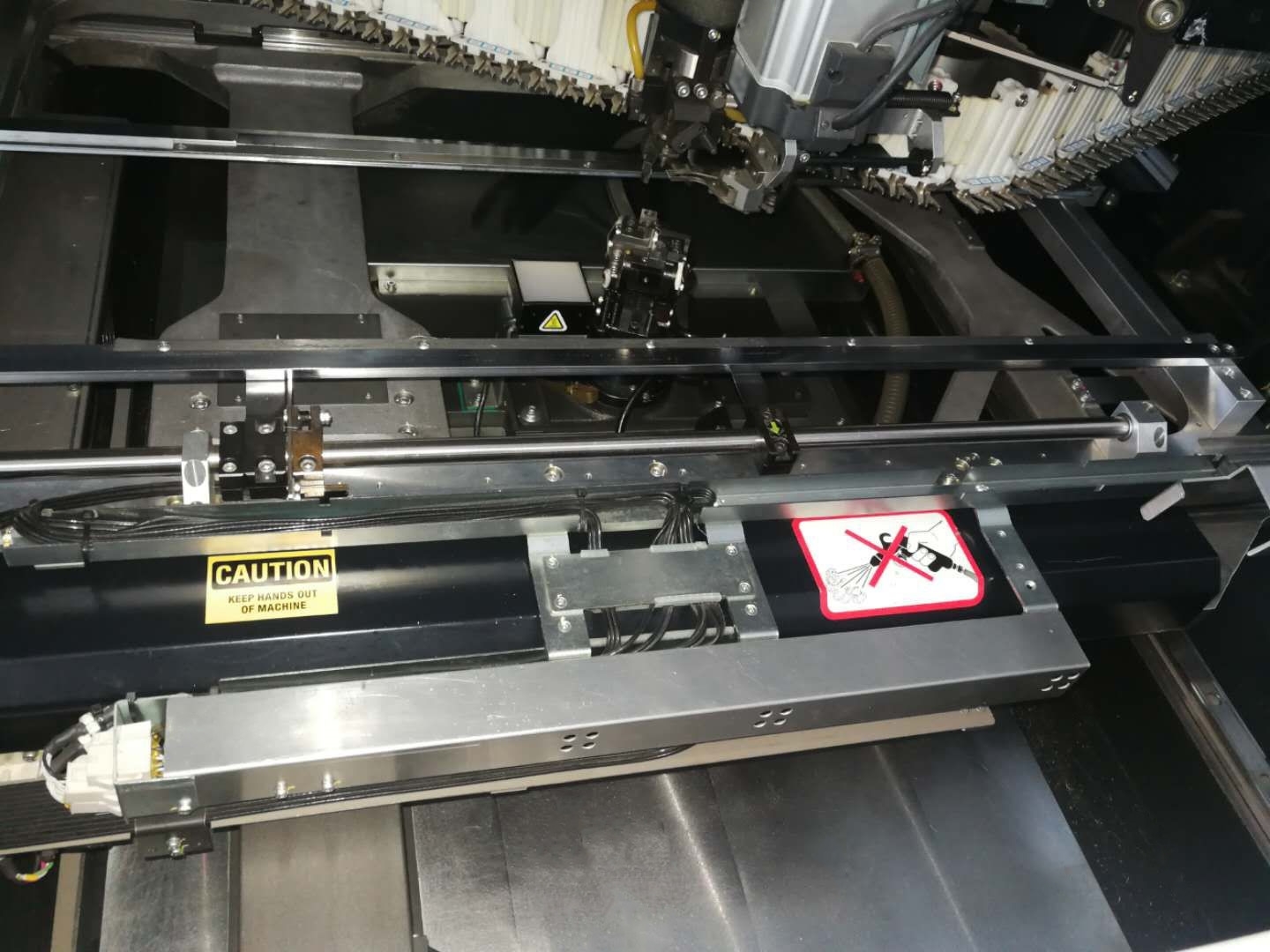

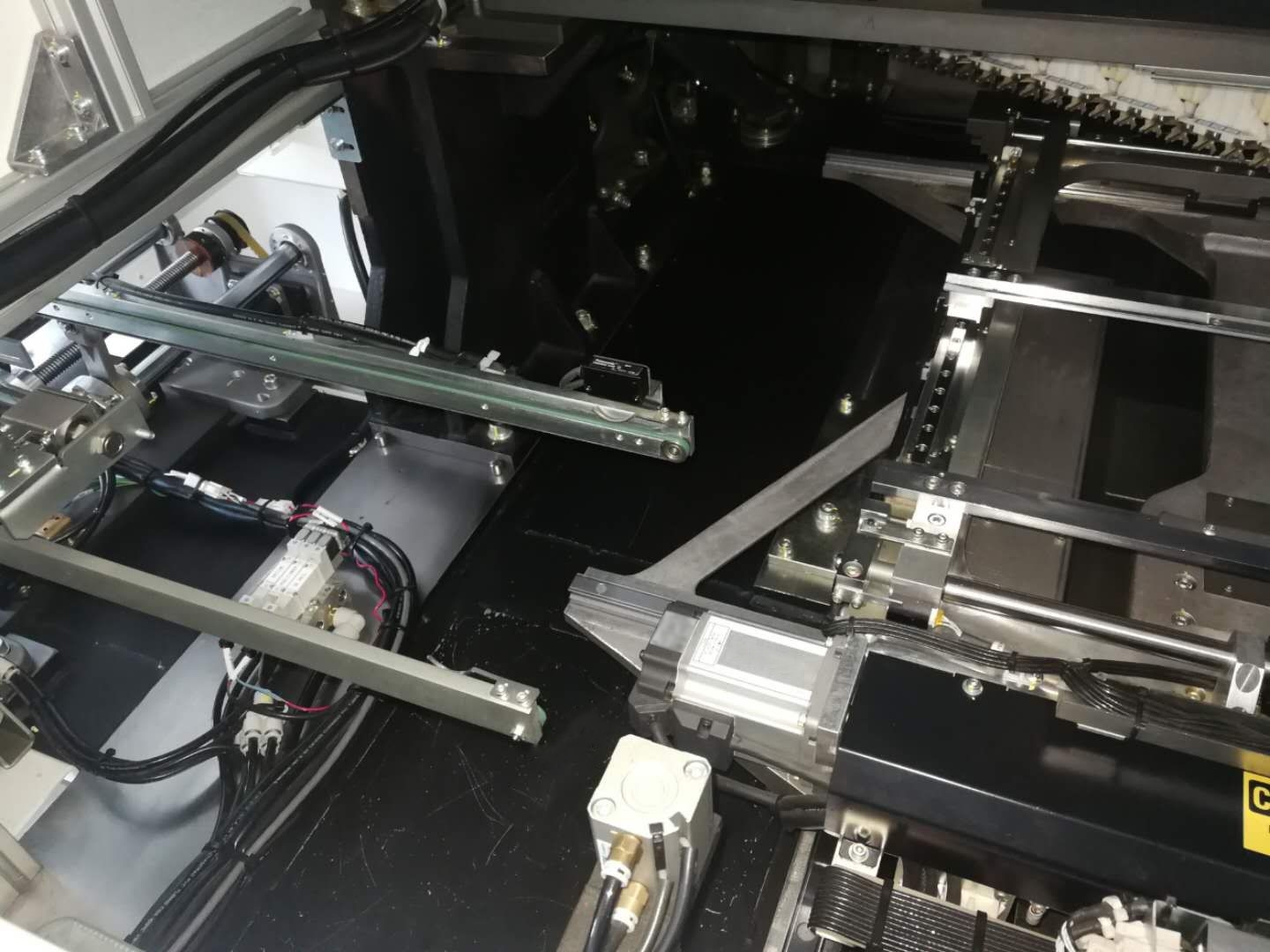

Radial inserter

Model: NM-EJR4A

(80) Stations

2.5 / 5.0 / 7.5 mm Span

With (30) single feeders

PCB Dimensions: 50 mm (L) x 50 mm (W) to 508 mm (L) x 381 mm (W)

Maximum speed: 0.25 seconds/component to 0.6 seconds/component

Number of component inputs: 80 (Connection mode), 40 +40 (Exchange mode)

Applicable components:

Pitch: 2.5 mm, 5.0 mm, 7.5 mm, 10.0 mm

Height: Maximum 26 mm

Diameter: Maximum 18 mm

Resistor

Electrolytic capacitor

Ceramic capacitor

LED

Transistor

Filter

Resistor network

PCB Exchange time: 2 seconds to 4 seconds (Room temperature 20°C)

Insertion direction: 4 Directions (0°, 90°, -90°, 180°)

Pneumatic source: 0.5 MPa, 80 L/min (A.N.R)

Power supply: 3 Phase, AC 200 V, 3.5 kVA

2011 vintage.

PANASONIC RG131 is a pc board assembly and manufacturing equipment designed to provide users with a reliable and efficient solution for high-volume and high-precision applications. The system is capable of processing boards from 1-19mm in thickness and in sizes up to 1,500mm by 500mm with a maximum board weight of 5.5kg. It offers a range of features including advanced laser vision displacement, integrated soldering and inspection systems, and intelligent software. The unit is engineered to move boards quickly and precisely within the workspace. The built-in laser vision displacement machine is capable of accurately locating and measuring fiducial marks and defining target points for various operations. The tool also provides manual and automatic x-y-z control across four axes, with accuracies up to 0.2mm, and high-precision accuracy feedback. This is done using independent stepper motors, as well as linear and rotary scales. PANASONIC RG 131 asset employs two integrated soldering systems for maximum precision and throughput. It is equipped with an advanced pneumatic soldering head which provides accurate and repeatable operations. Additionally, it also includes an integrated desktop soldering iron which is capable of precise soldering temperatures. The model is also capable of preheating and cooling the boards as required. The equipment is also equipped with a full suite of software tools which allow users to control all of the system's functions, including creating production recipes, quality control settings, and process monitoring. The software also supports remote monitoring, video management, and data logging. RG131 is designed for maximum uptime. The unit is engineered for low power consumption, and it includes features such as an integrated power optimisation machine, and a robust environmental case. It also includes a maintenance mode which can help prevent downtime and improve operational reliability. Additionally, the tool encompasses a wide range of safety features such as a lid interlock asset, an emergency stop switch, as well as electromagnetic radiation protection. In conclusion, RG 131 is an innovative model for automated assembly and manufacturing processes. Its advanced features, intuitive software, and efficient design make it an ideal solution for high-volume and high-precision applications. It provides users with a reliable and efficient solution for their production needs, and its robust design ensures maximum uptime and improved reliability.

There are no reviews yet