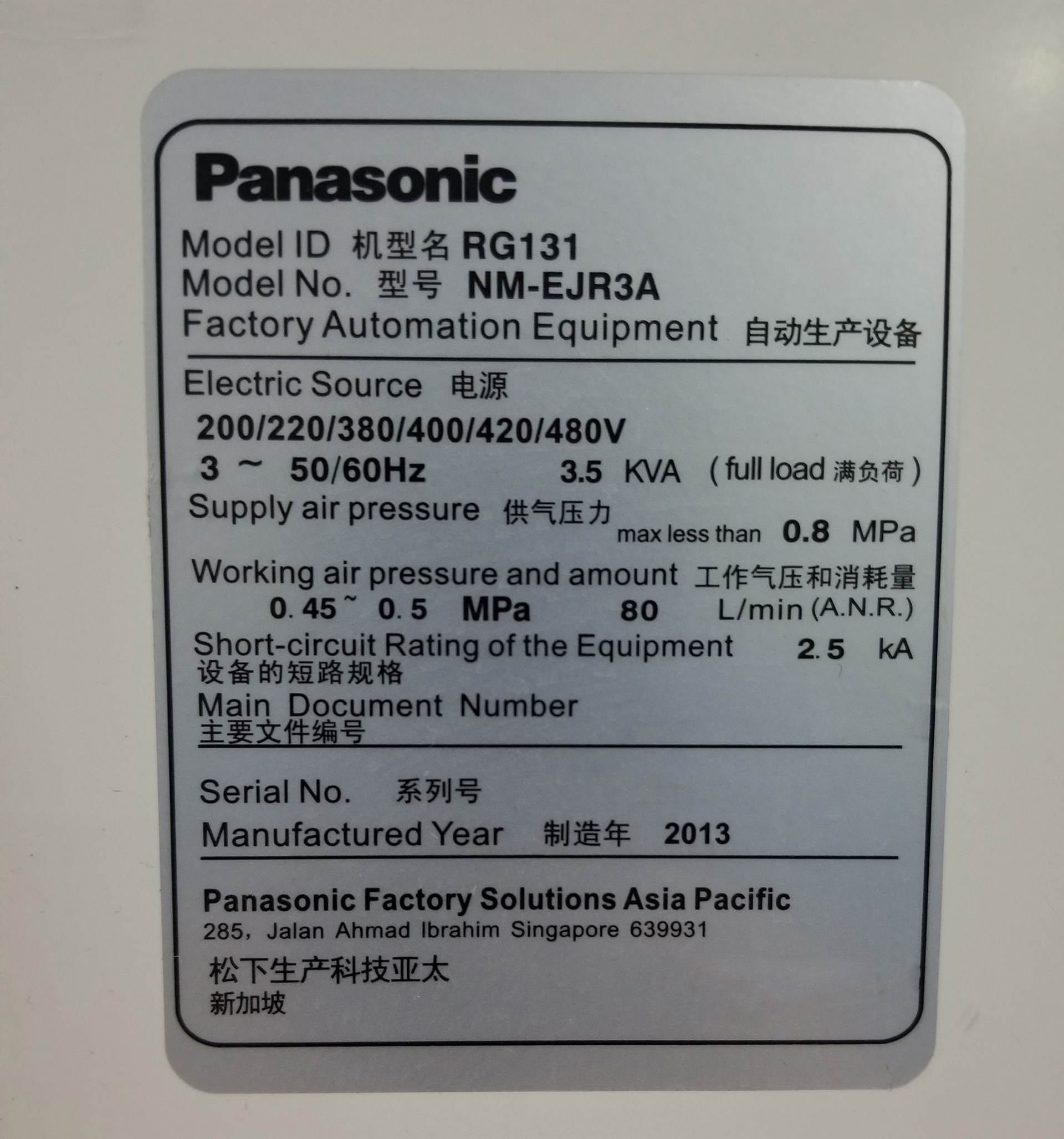

Used PANASONIC RG131 #9249709 for sale

URL successfully copied!

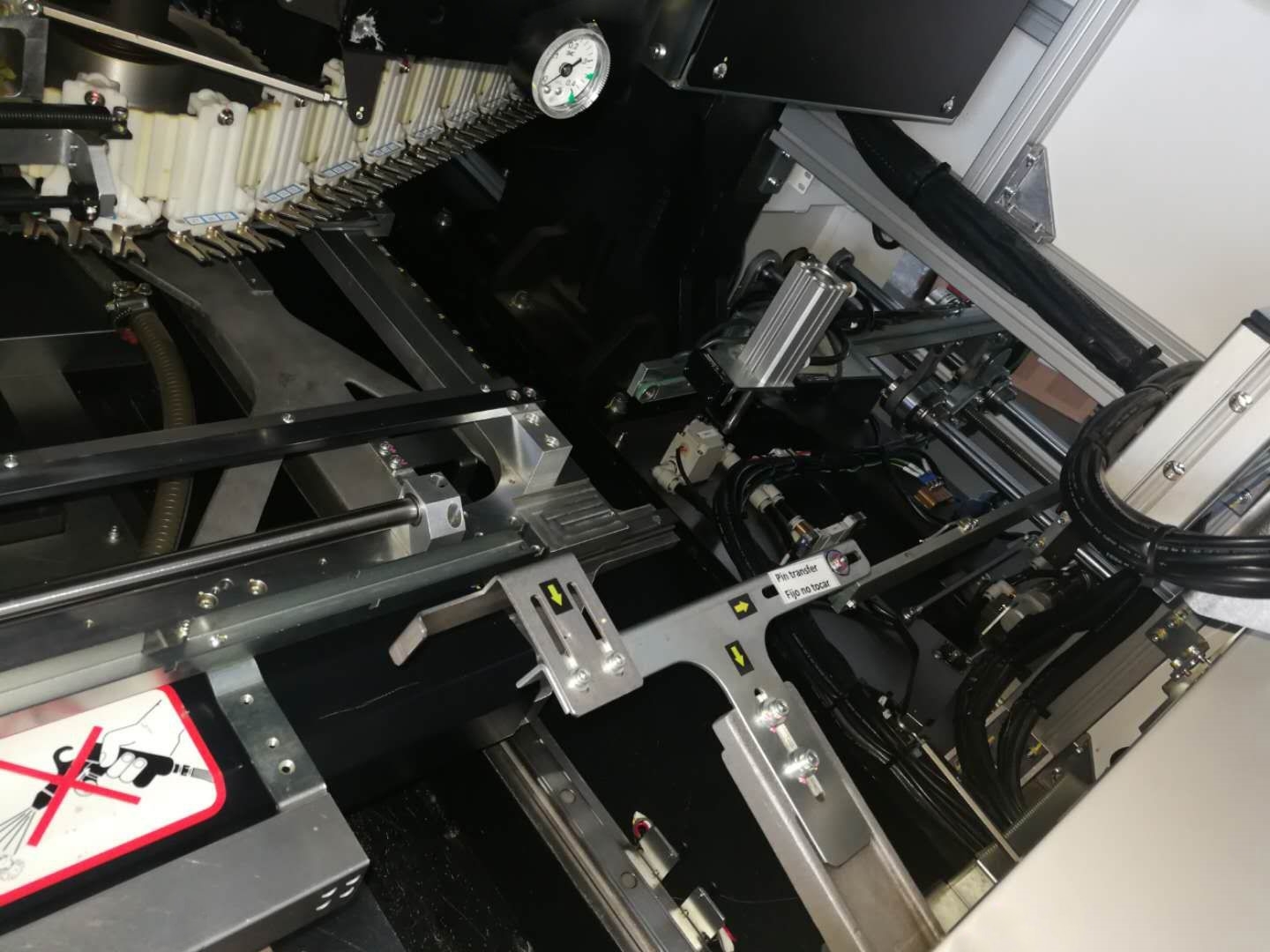

Tap to zoom

ID: 9249709

Vintage: 2013

Radial inserter

Model: NM-EJR3A

(40) Stations

2.5 / 5.0 mm Span

With (30) single feeders

PCB Dimensions: 50 mm (L) x 50 mm (W) to 508 mm (L) x 381 mm (W)

Maximum speed: 0.25 seconds/component to 0.6 seconds/component

Number of component inputs: 40

Applicable components:

Pitch: 2.5 mm, 5.0 mm, 7.5 mm, 10.0 mm

Height: Maximum 26 mm

Diameter: Maximum 18 mm

Resistor

Electrolytic capacitor

Ceramic capacitor

LED

Transistor

Filter

Resistor network

PCB Exchange time: 2 seconds to 4 seconds (Room temperature 20°C)

Insertion direction: 4 Directions (0°, 90°, -90°, 180°)

Pneumatic source: 0.5 MPa, 80 L/min (A.N.R)

Power supply: 3 Phase, AC 200 V, 3.5 kVA

2013 vintage.

PANASONIC RG131 is a PC board assembly and manufacturing equipment designed for high volume production lines. The system offers a comprehensive range of components that make it easy to construct and debug complex designs. It's an efficient unit that can be used to quickly generate assemblies with high-quality parts, cost-effectively and with minimal human interaction. The machine is made up of a number of components that are specific to building and maintaining PC boards. These components include Printed Circuit Board (PCB) blanking machines, component placement machines, multi-function testers, inspection equipment and special sensor detectors. The components are designed to work together to build PC boards that are precise and accurate. PANASONIC RG 131's specialized component placement machines are equipped with powerful 'fly-by-wire' technology that enables the flexible placement of components of any size. This feature reduces errors and minimizes material wastage compared with traditional methods. The tool also features a powerful tracking asset to monitor and control all processes and materials used for assembly, which means that quality control and production are both maximized. The model's specialized inspection equipment includes blowers, X-Ray monitors, cameras and ultrahigh-definition imaging technology that can detect even the smallest defects on PC boards. This helps ensure that every board passes a high standard of quality requirements. The equipment also features a range of specialized software that is specifically designed for the manufacturing of PC boards. This software makes it easy to control all aspects of the production process, from generating packages to controlling the assembly process, with detailed logs and reports so that all these processes can be tracked and monitored. Overall, RG131 is a fast, efficient, and reliable system for assembling and manufacturing Printed Circuit Boards. Its powerful components and software enable it to support high-volume production lines, while ensuring that all PC boards meet high levels of quality and accuracy that is essential for the modern electronics industry.

There are no reviews yet