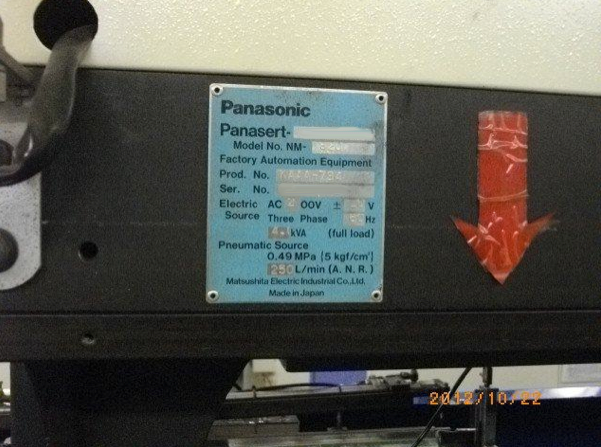

Used PANASONIC RH3 NM-8224B #9017550 for sale

URL successfully copied!

Tap to zoom

ID: 9017550

Vintage: 1998

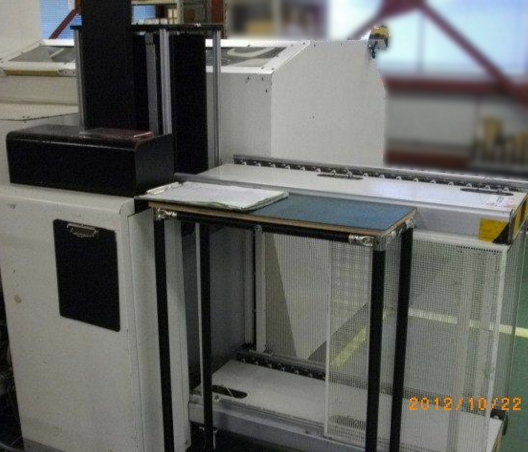

Radial inserter

With loader and unloader

Right to left

Front rail fixed

Soundproofing/safety full cover

Board size M: max 330×250mm

Tact: 0.36 sec(4 steps swiching)

Self-correction camera

Bourd entry: pusher type ( loader)

Bord exit: pusher type (unloader)

V-cut /2 toolings: (2.5/5.0mm insertion)

Components carriage: 62 kinds

Anvil: 35 degrees

AC servomotor

Auto-recovery

Bad mark

Cassette feeder: TTL 56 pcs

Cassette feeder 5.0mm: (52) pieces

Cassette feeder 2.5mm: (04) pieces

Cut dust catcher

Rail-width auto-adjust

RS232C

Large size components: D13/Hn21/L22.5/W1

1998 vintage.

PANASONIC RH3 NM-8224B is a high-performance PC board assembly and manufacturing equipment that is capable of quickly and accurately assembling small to medium-sized printed circuit board assemblies (PCBAs). It is capable of assembling SMD, through-hole, components and connectors. The RH3 uses a multi-axis spine-based system to achieve fast assembly rates and smooth production. It can be equipped with up to 8 heads for component loading, up to 4 heads for pick and place, and 4 heads for soldering. The RH3 has a 12" touchscreen interface for easy programming, with its own visualization software. With this software, users can quickly and easily create and edit process programs and design data, while at the same time monitoring production status. This machine has automatic calibration and error detection capabilities, allowing for rapid diagnostics and accuracy. It also features memory slot capabilities for production lot recall, for quickly editing production jobs or executing recall orders. The RH3 is capable of handling a wide range of components, from fine pitched 0402 size components to large 14x14mm parts. It has an optional I/O conveyor that allows it to be connected to other machines for automatic component transfer and load locking. A rail mounted 1M camera for 2D vision inspection unit is available. This feature ensures accurate placement of small components and helps to reduce re-work or repair costs. The RH3 also has an optional feeder management capability that supports a variety of feeder trays and ensures efficient material usage. A two-axes flying camera option is available, which can be used for off-line programming and laser mark inspection. This significantly speeds up engineering for new products. Additionally, the machine is capable of working in both near-infrared and laser soldering operations to meet a wide range of soldering requirements. RH3 NM-8224B is a highly advanced and reliable PC board assembly and manufacturing machine. It is capable of handling various components for assembly, testing, and inspection, and features easy programming and recall capabilities. Not only does it provide a smooth and reliable workflow, but it is well suited for both small and medium-sized production runs.

There are no reviews yet