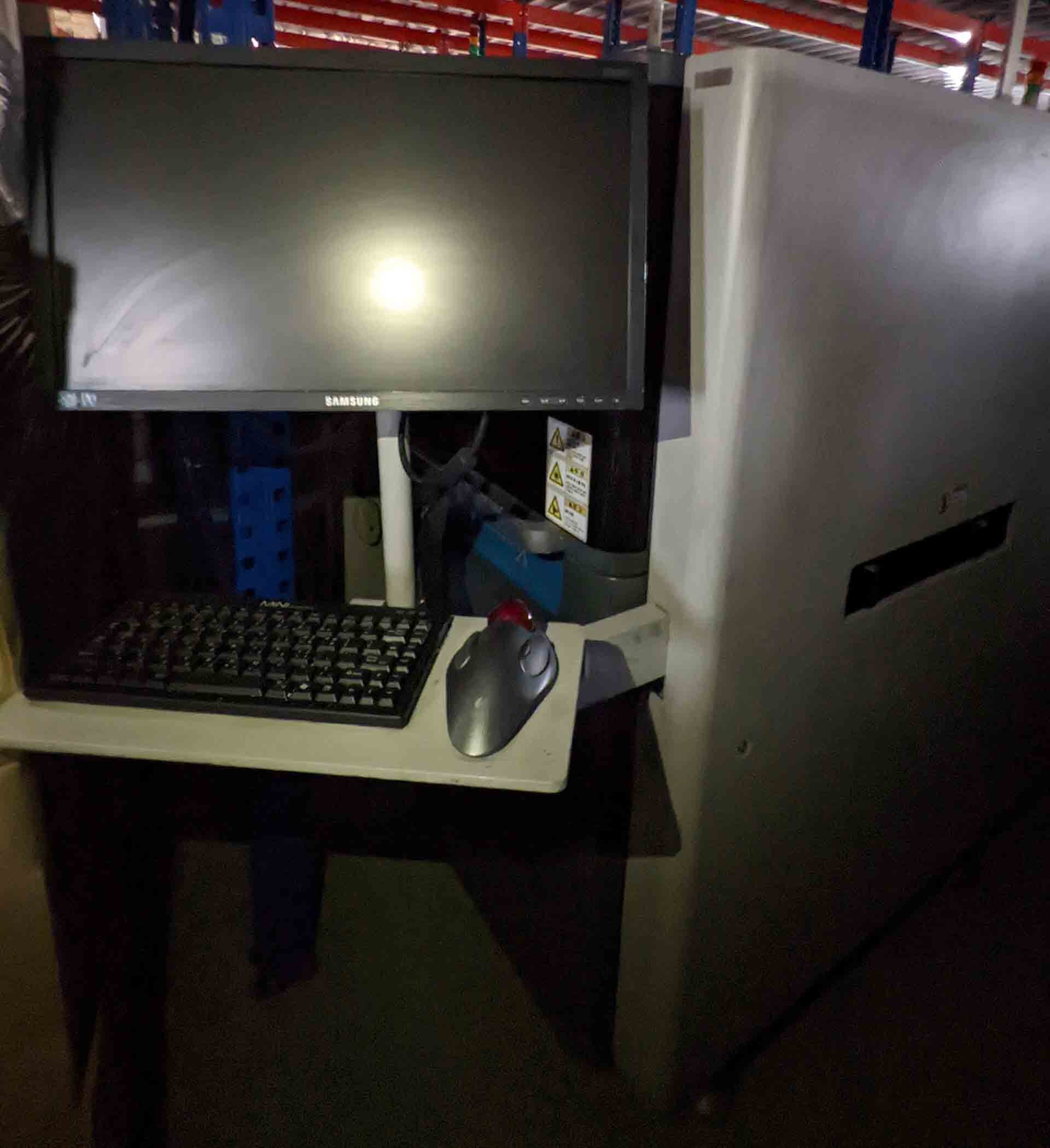

Used PARMI SIGMA X #293604988 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

PARMI SIGMA X is a PC board assembly and manufacturing equipment specifically designed for the assembly and rework of printed circuit boards (PCBs) with mixed component packages. Using its easy-to-use GUI, users can easily select from a wide selection of configurations to meet their specific requirements. Additionally, the system can accommodate parts from a wide variety of suppliers, allowing for great flexibility in component selection for assembly and rework operations. The unit provides a variety of functions for the assembly and rework of actual components, including pick and place, reflow soldering, and rework-alignment. The pick and place tool is able to accurately perform placement of components on a PCB in one step, thus eliminating the need for hand-soldering individual components. This is possible due to the advanced vision machine, which is capable of recognizing components, as well as detecting misalignments and off-cuts. The reflow soldering tool is optimized for soldering SMD and thru-hole components. It is able to provide precision temperature and flow control, as well as highly accurate placement of solder paste and rinsing. Additionally, with its intuitive programming tools, users can create settings for rework-alignment in order to accurately reshape and modify components that have been misaligned. SIGMA X also offers advanced traceability tracking, allowing users to monitor the production and quality of their devices. Its built-in quality tracking tool allows users to identify the location and process flow of components, detecting and minimizing the risk of errors and product malfunctions. Overall, PARMI SIGMA X is an incredibly versatile and reliable asset for PC board assembly and rework, offering users a wide variety of features and capabilities. Its intuitive GUI, powerful functionality, and advanced traceability tracking make it an ideal choice for assembly and rework solutions.

There are no reviews yet