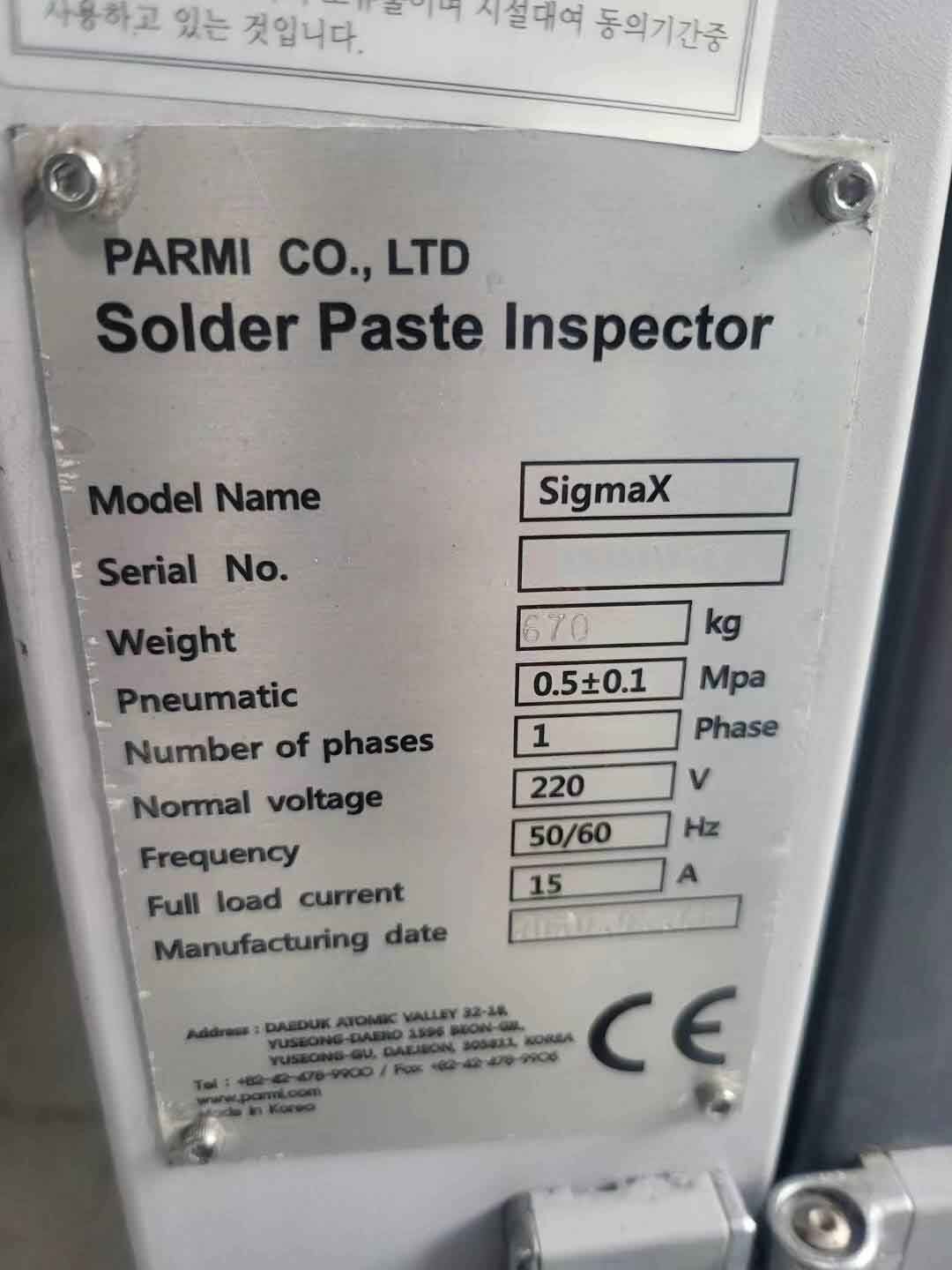

Used PARMI SIGMA X #293626808 for sale

URL successfully copied!

Tap to zoom

PARMI SIGMA X is an advanced PC board assembly and manufacturing equipment that enables the production of high-quality printed circuit boards (PCBs) in large volumes. The system consists of three core components: a placement machine, a reflow oven and an inspection unit. The placement machine is responsible for placing and soldering electronic components to a printed circuit board. It uses an advanced vision machine to detect and place components accurately, and a precision pick-and-place head to ensure that each component is placed accurately. The reflow oven is responsible for creating the heat profile needed to solder components to the PCB. It uses a convection-style heating tool that produces precise, repeatable results. Finally, the inspection asset is used to ensure that each board is built to exacting standards. It incorporates advanced image analysis software that can detect even the slightest errors in solder application, component placement and PCB fabrication. SIGMA X provides manufacturers with an automated, reliable and accurate manufacturing process for printed circuit board assembly. Its advanced placement machine ensures that components are placed with precision and accuracy, while the reflow oven ensures that the solder joints are of the highest quality. In addition, the inspection model allows for the verification of each PCB before final shipment, ensuring consistent product quality. Combined, these components make PARMI SIGMA X the ideal solution for mass producing high-quality printed circuit boards in large volumes.

There are no reviews yet