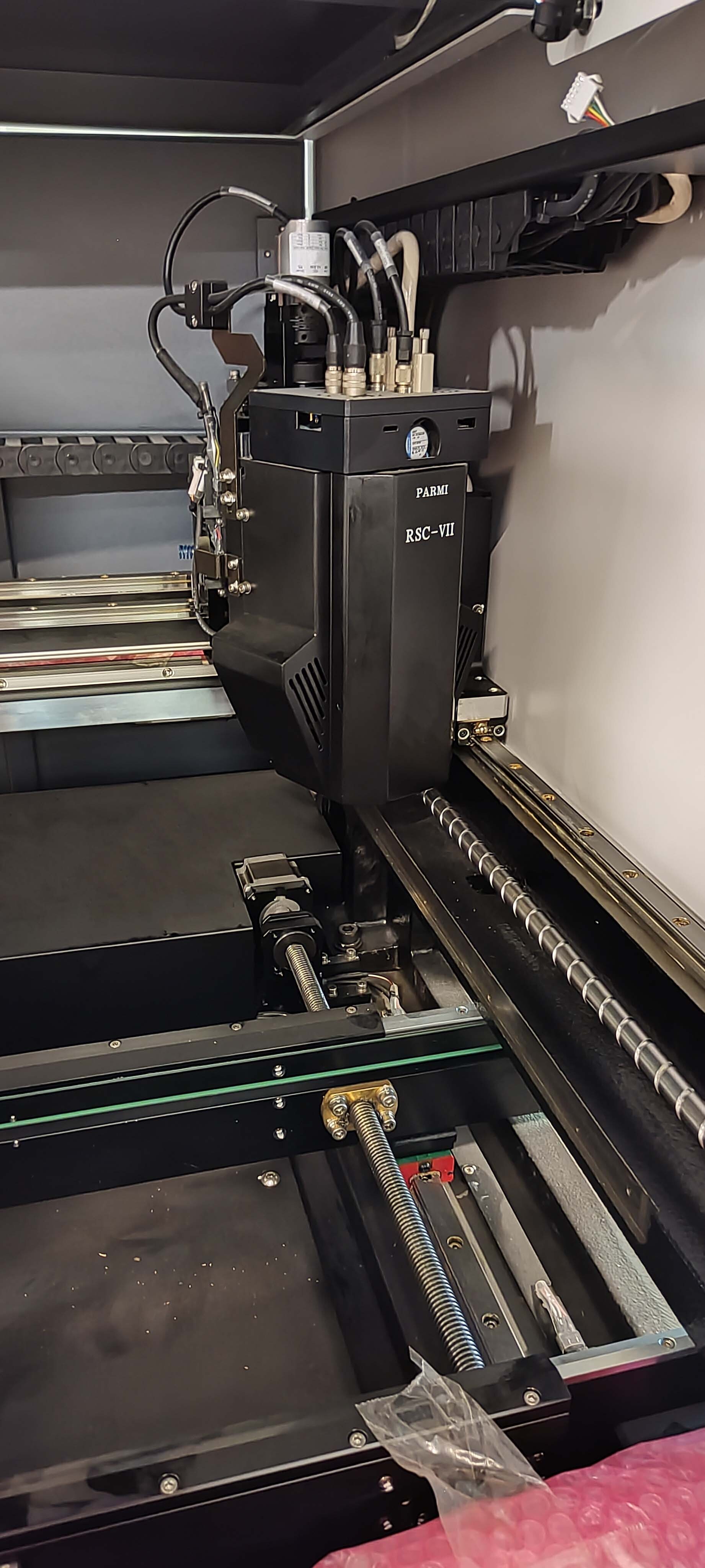

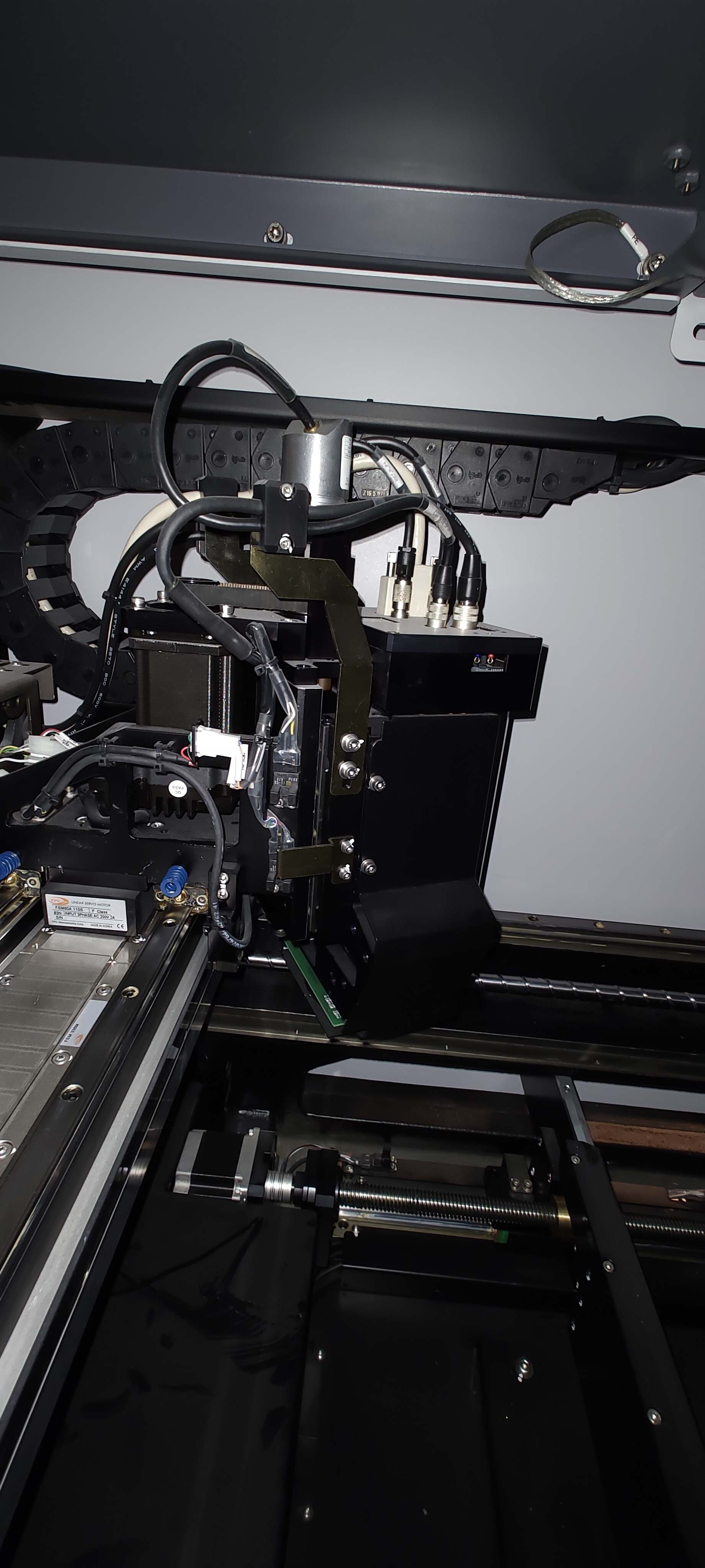

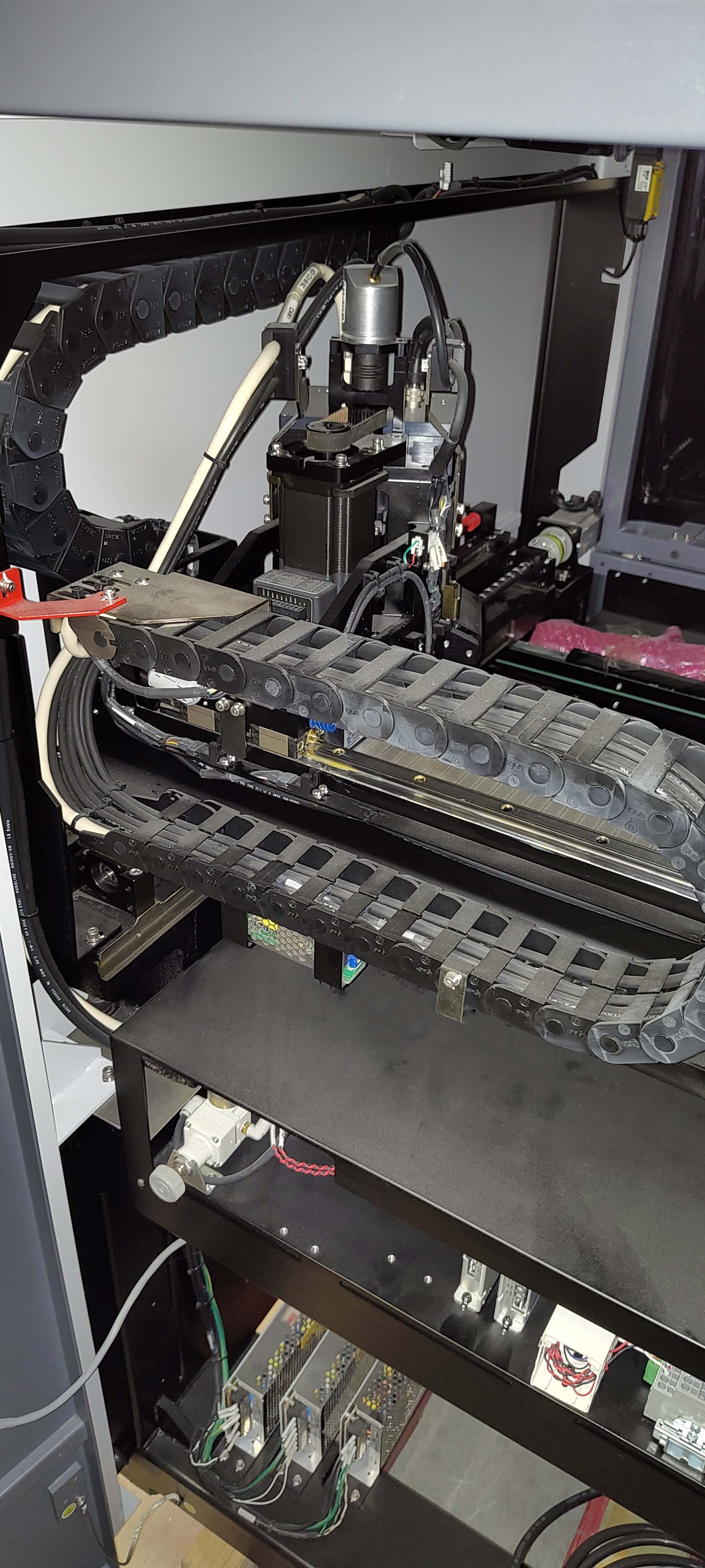

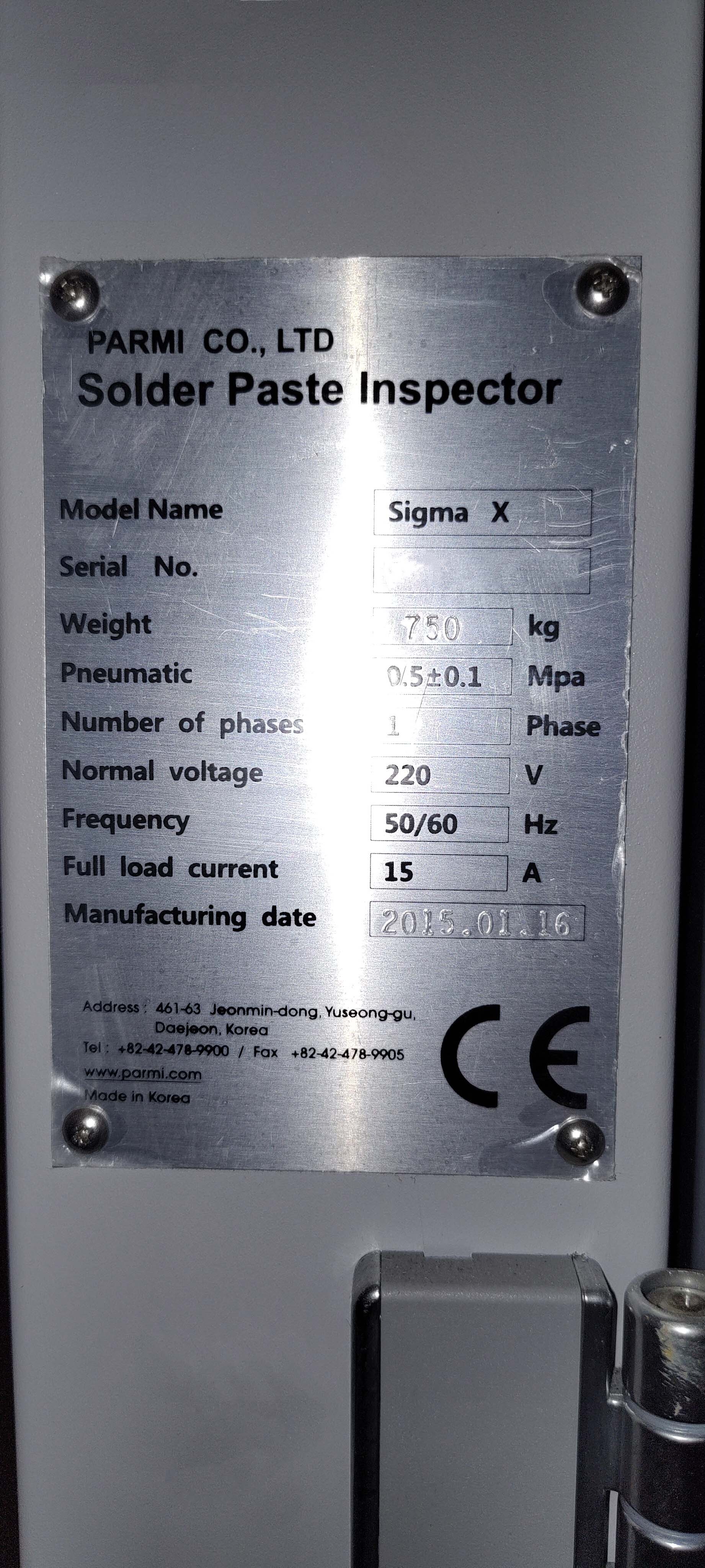

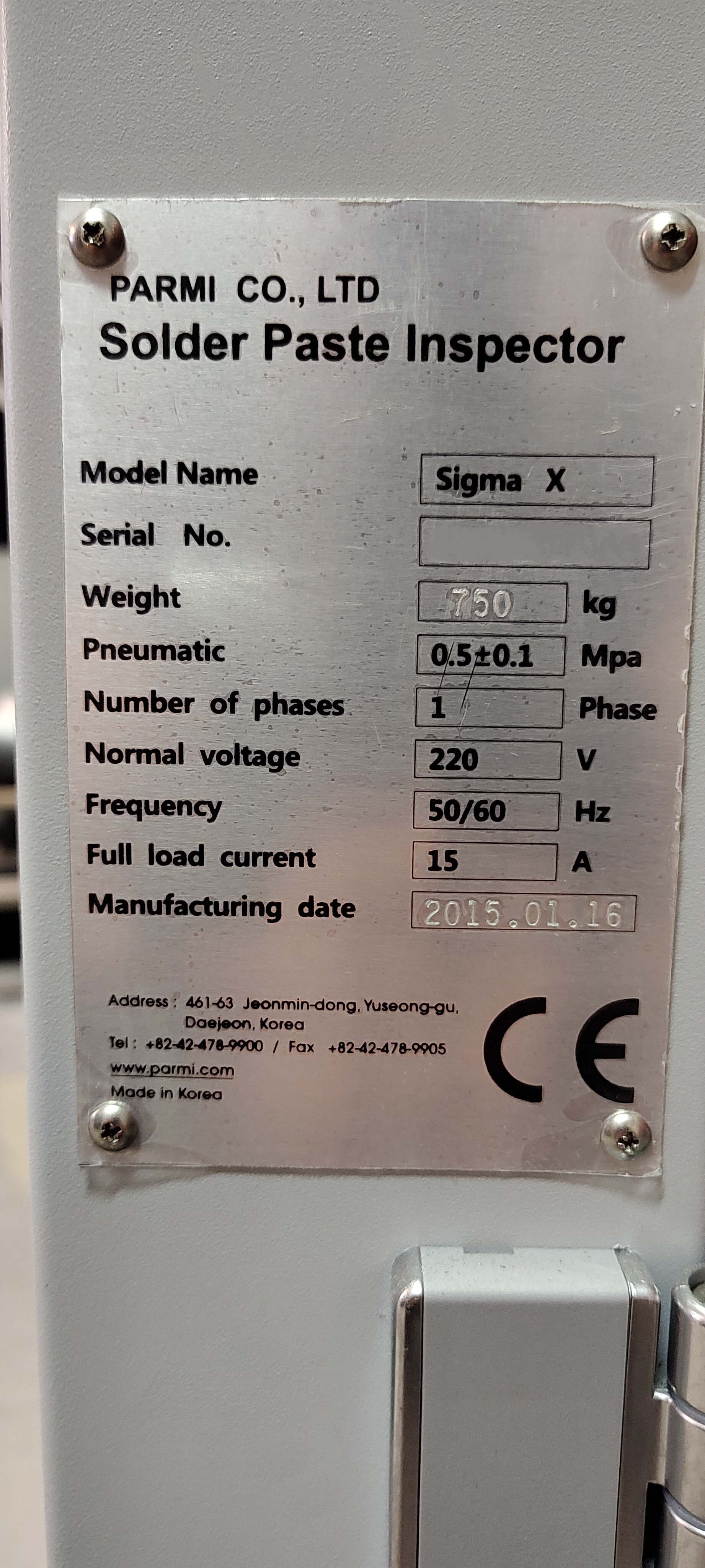

Used PARMI SIGMA X #293667181 for sale

URL successfully copied!

Tap to zoom

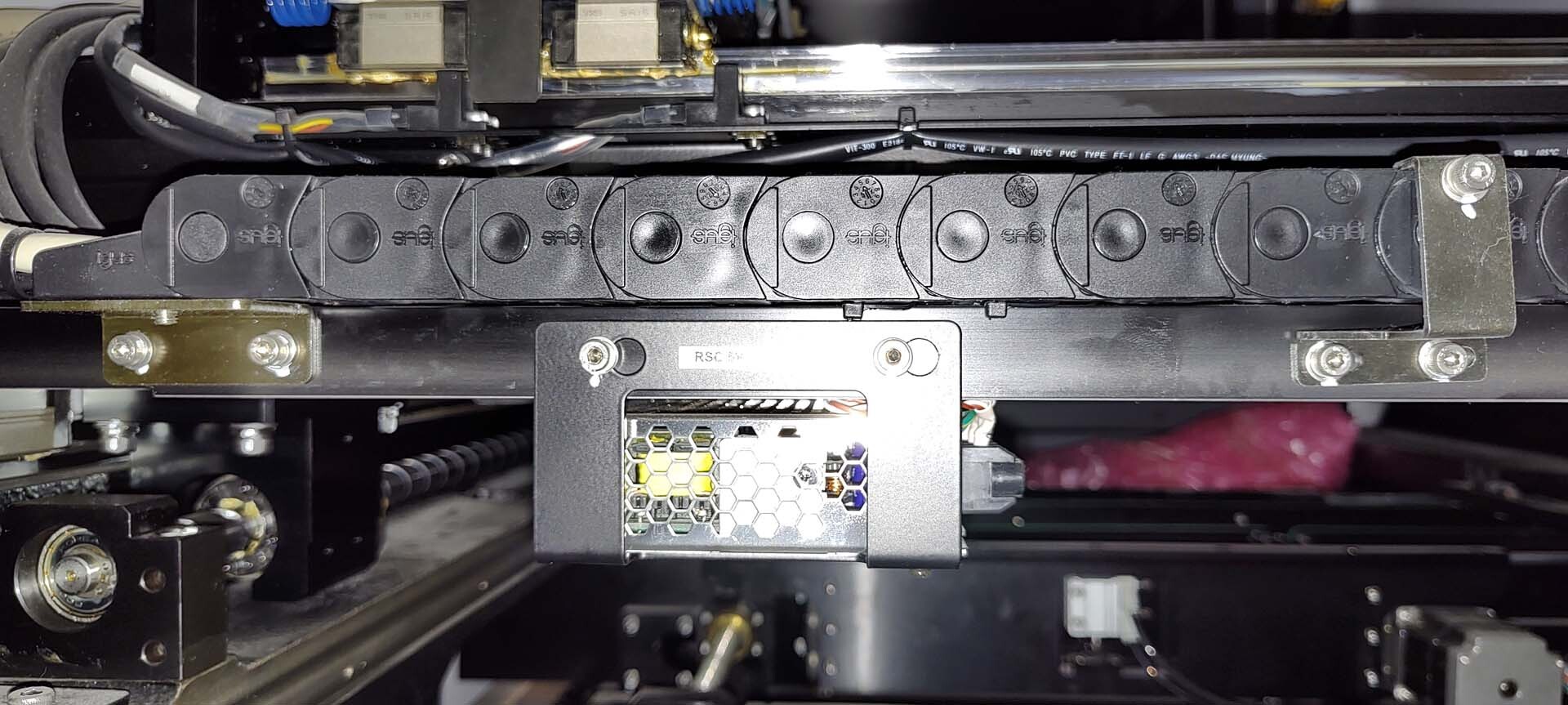

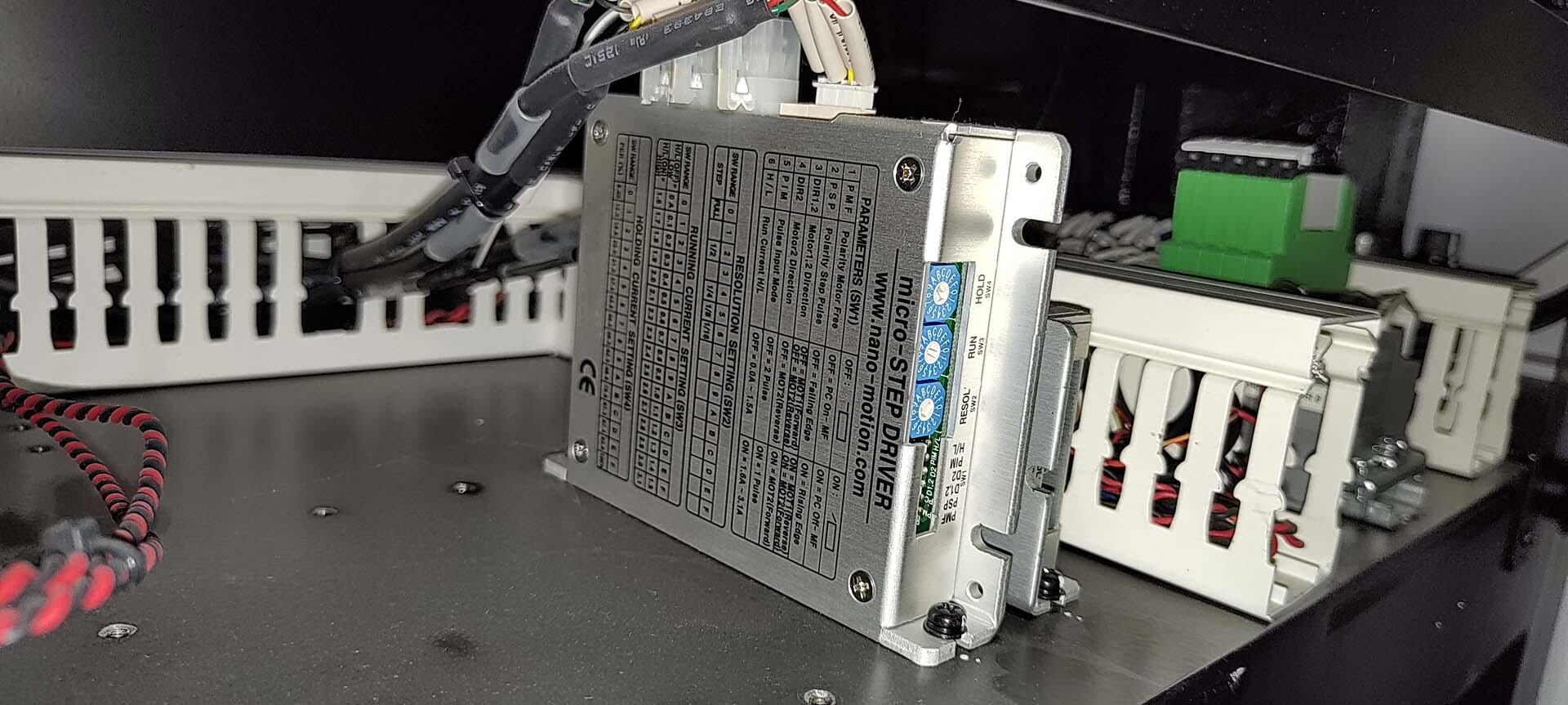

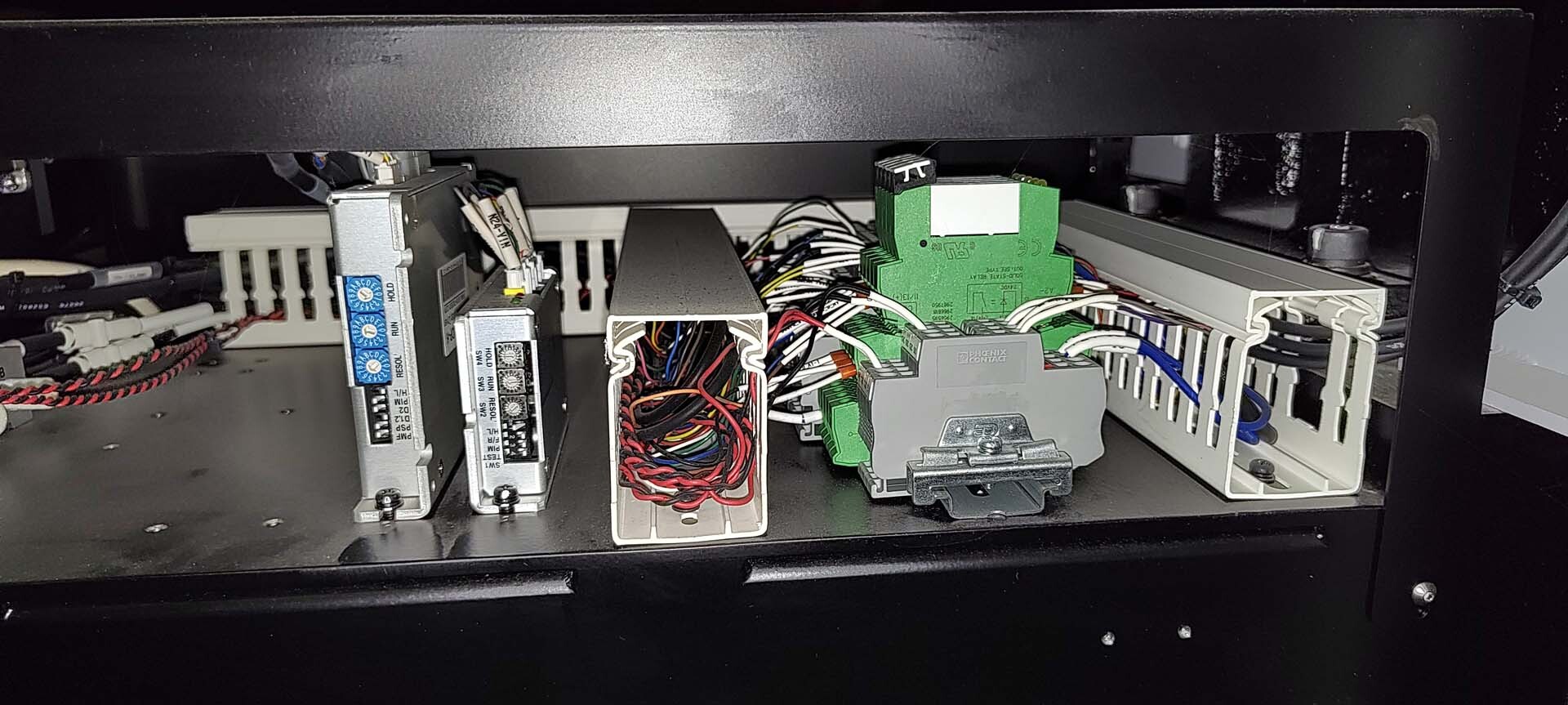

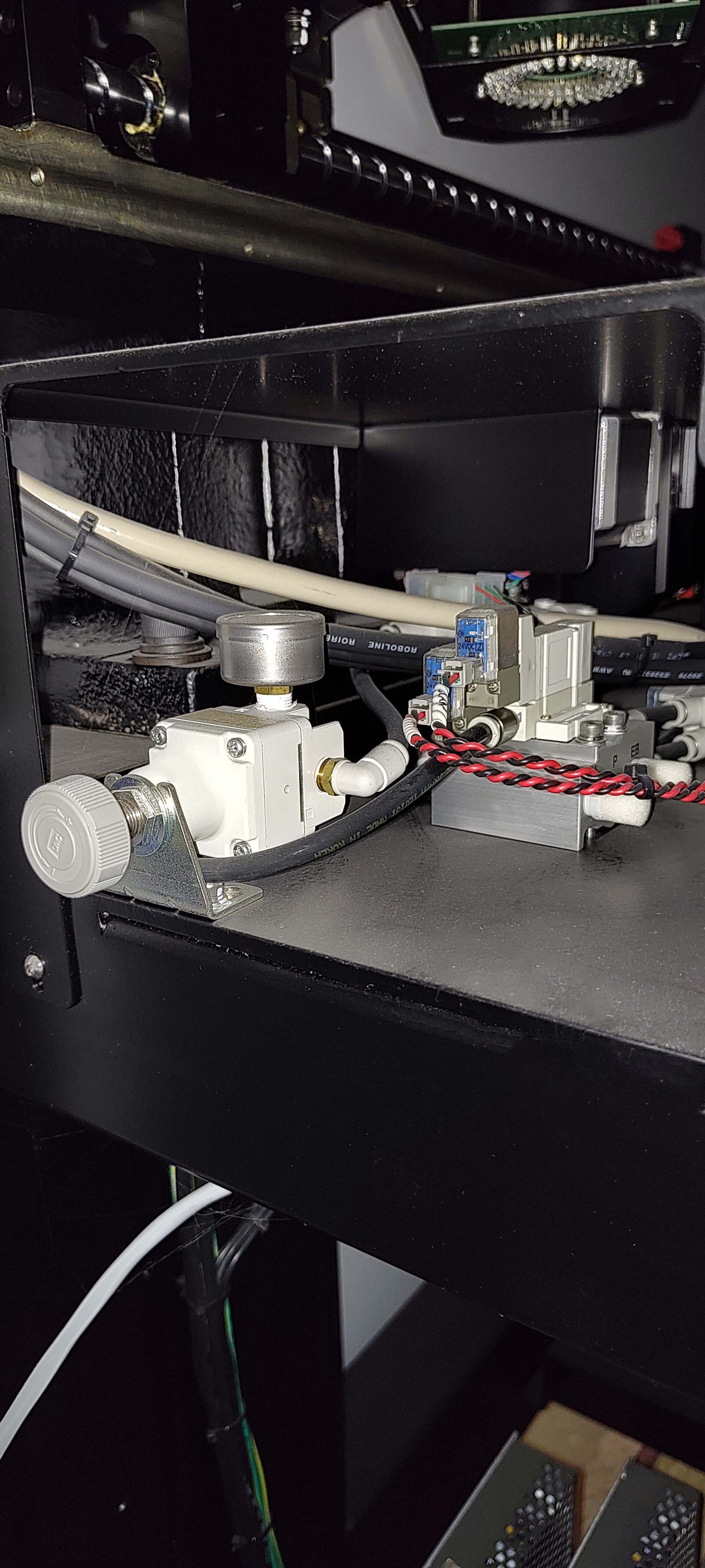

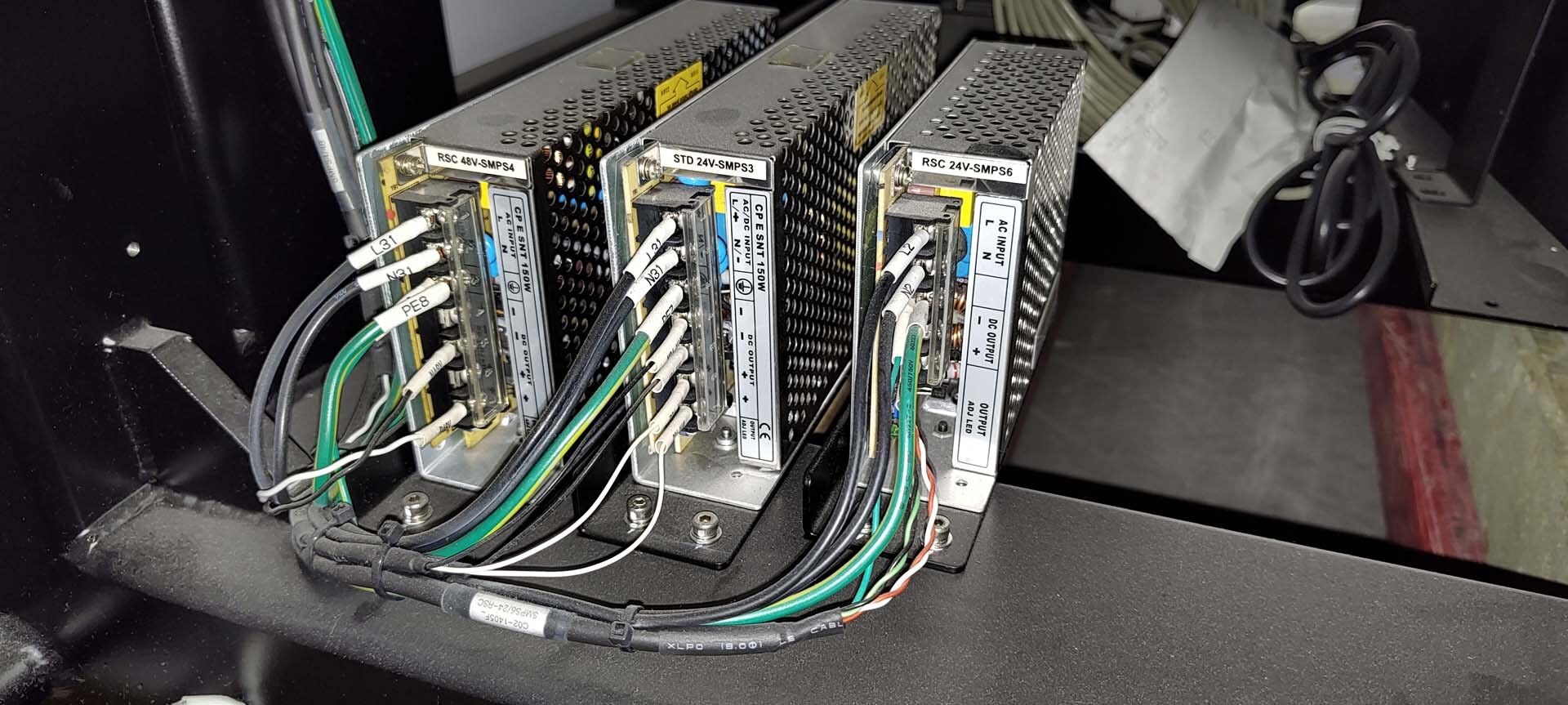

PARMI SIGMA X is a dynamic, automated PC board assembly and manufacturing equipment that accommodates each unique project's needs. Designed for continuous, high-quality production, it uses the latest technologies to streamline assembly and manufacturing processes. The system is composed of several manufacturing and assembly components, all of which offer various advantages. Starting with material loading, the unit efficiently manages all components entering the work site. From here, the entire assembly process is done with robotic arms and integrated with a finely tuned CAD/CAM machine that guides each step of the operation. This allows for combined man-machine operations at a high level of precision. Downstream of the material loading tool, SIGMA X comes with several tools for the assembly and manufacturing processes, such as the solder paste printing of circuits, placement of components, pick-and-place, dispense/stencil, and more. All of this is seamlessly integrated with an automated soldering asset, as well as a 3D vision model that allows for inspection. Finally, downstream and downstream/Supportive quality assurance inspections can be programmed in with built-in features such as a programming tool for automatic wiring inspections, as well as an inspection tool and imagery recognition that evaluates components placed on the board. Moreover, it also comes with an X-Ray inspection that is used to detect potential shorts but also for general verification of the assembly process. In a nutshell, PARMI SIGMA X is a perfect fit for any organization looking for a robust PC board assembly and manufacturing equipment that can effectively streamline and automate the entirety of the production process, while maintaining the utmost level of precision and quality assurance. It boasts a set of tools and features that can be tailored to meet ever-evolving production requirements.

There are no reviews yet