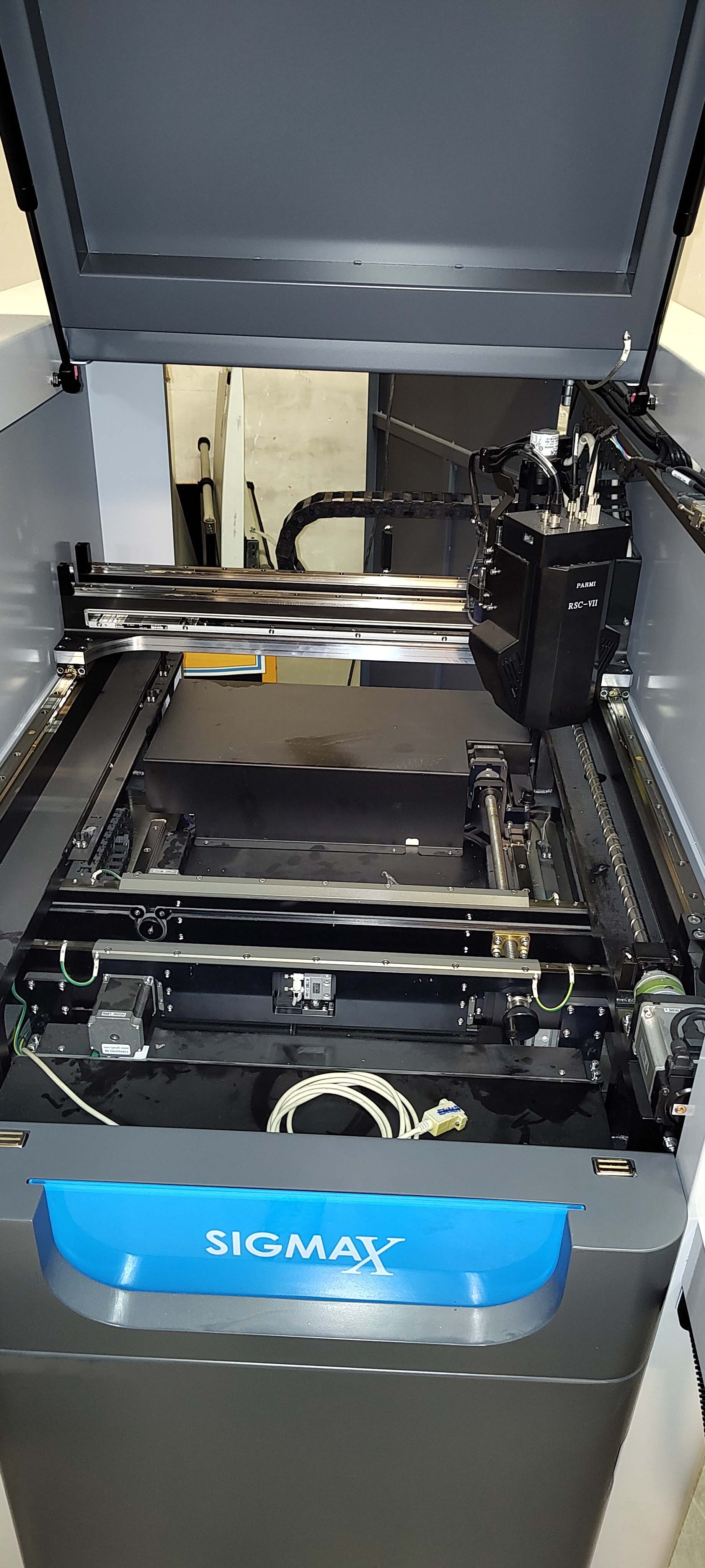

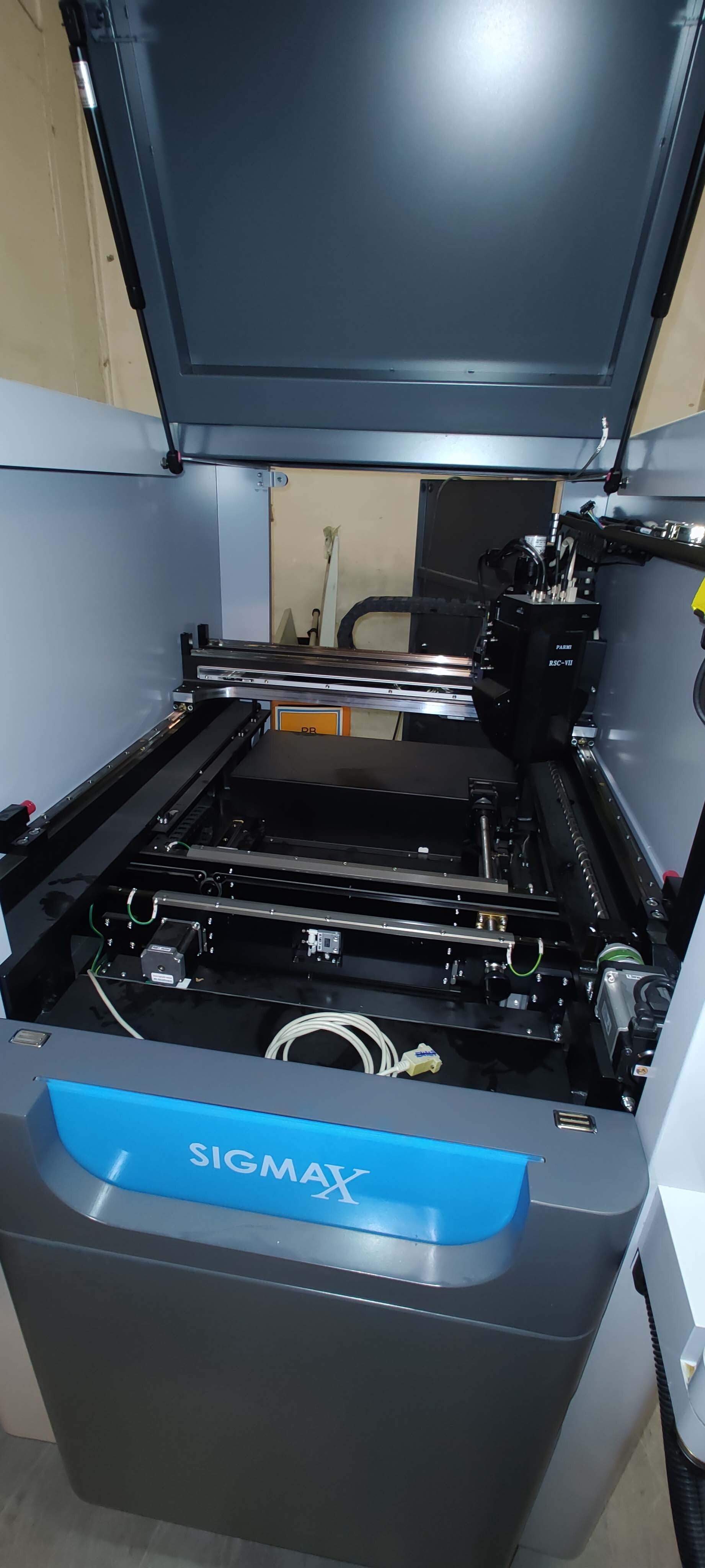

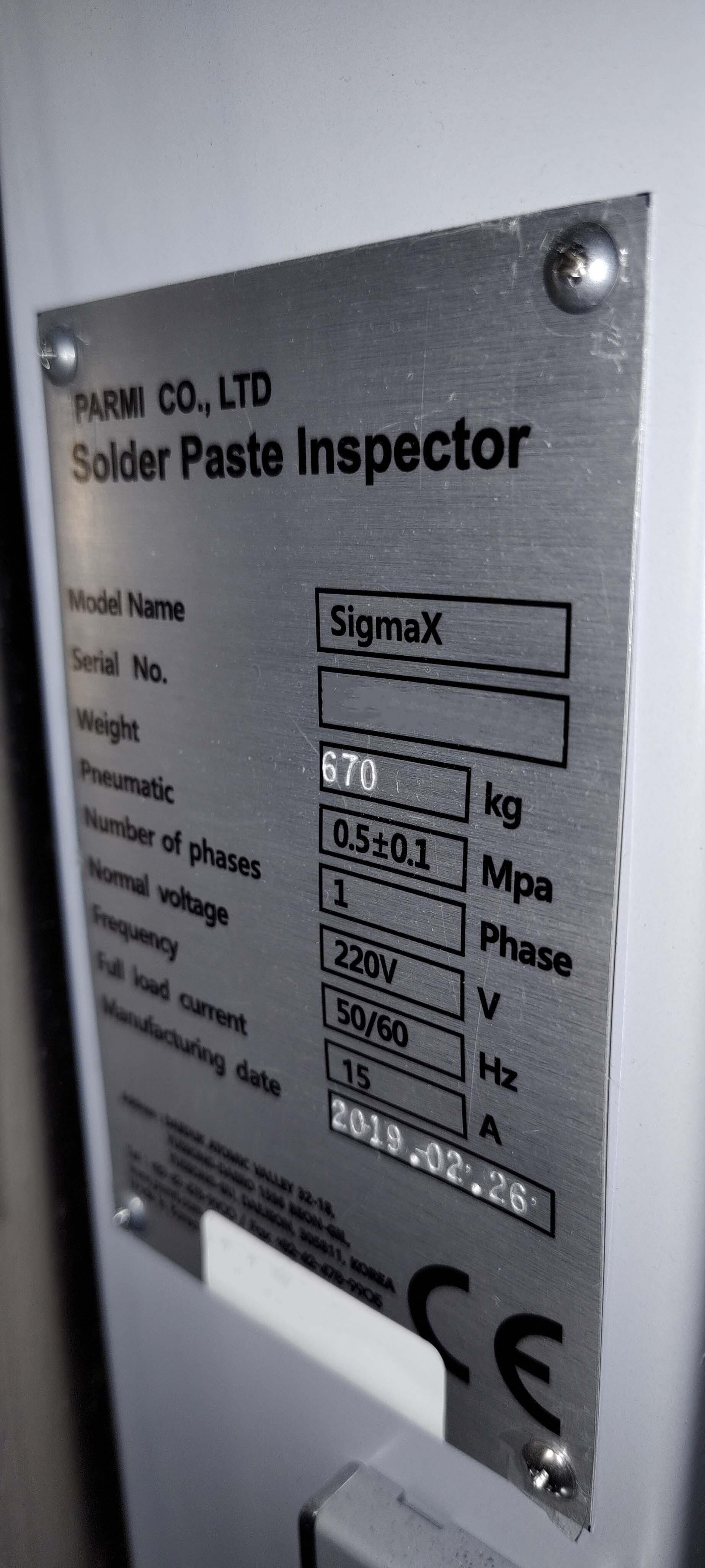

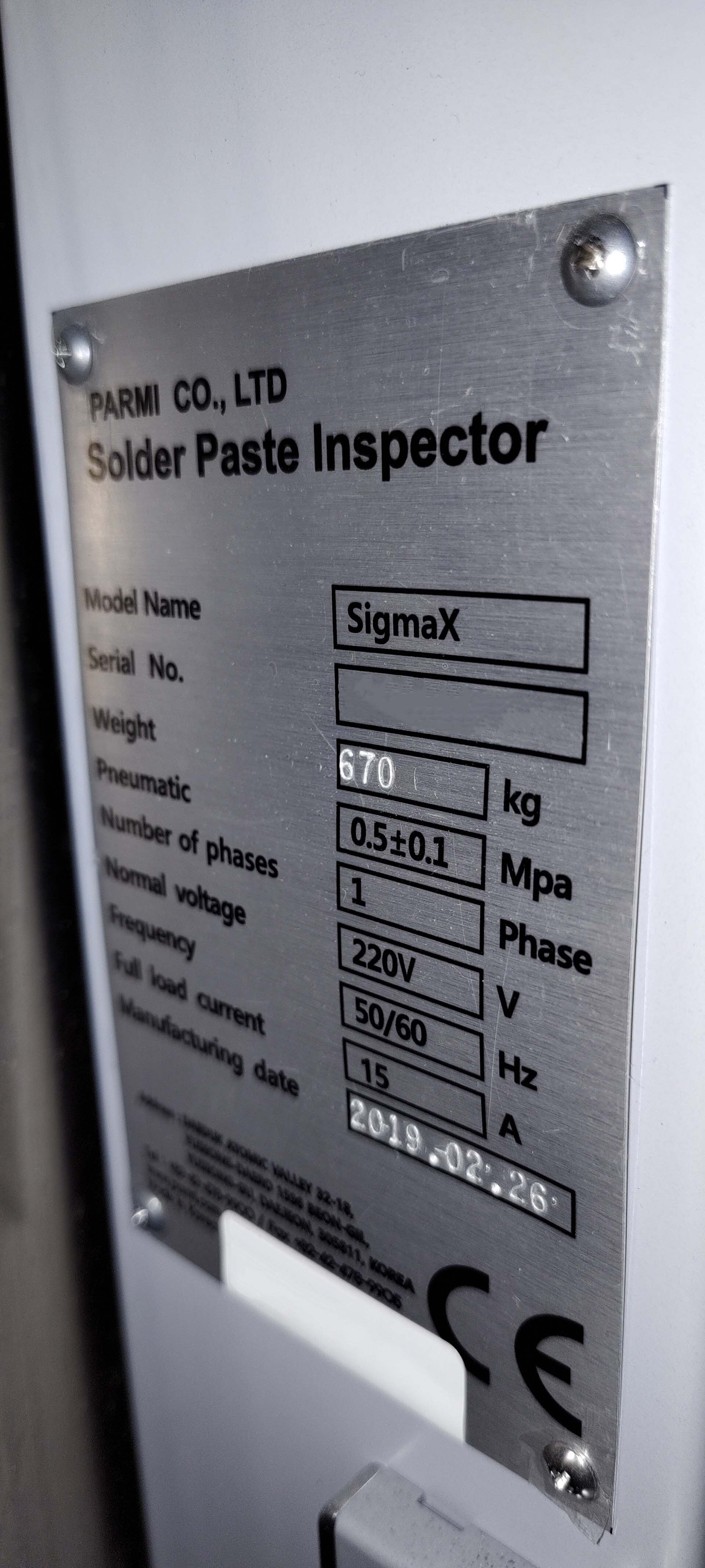

Used PARMI SIGMA X #293667184 for sale

URL successfully copied!

Tap to zoom

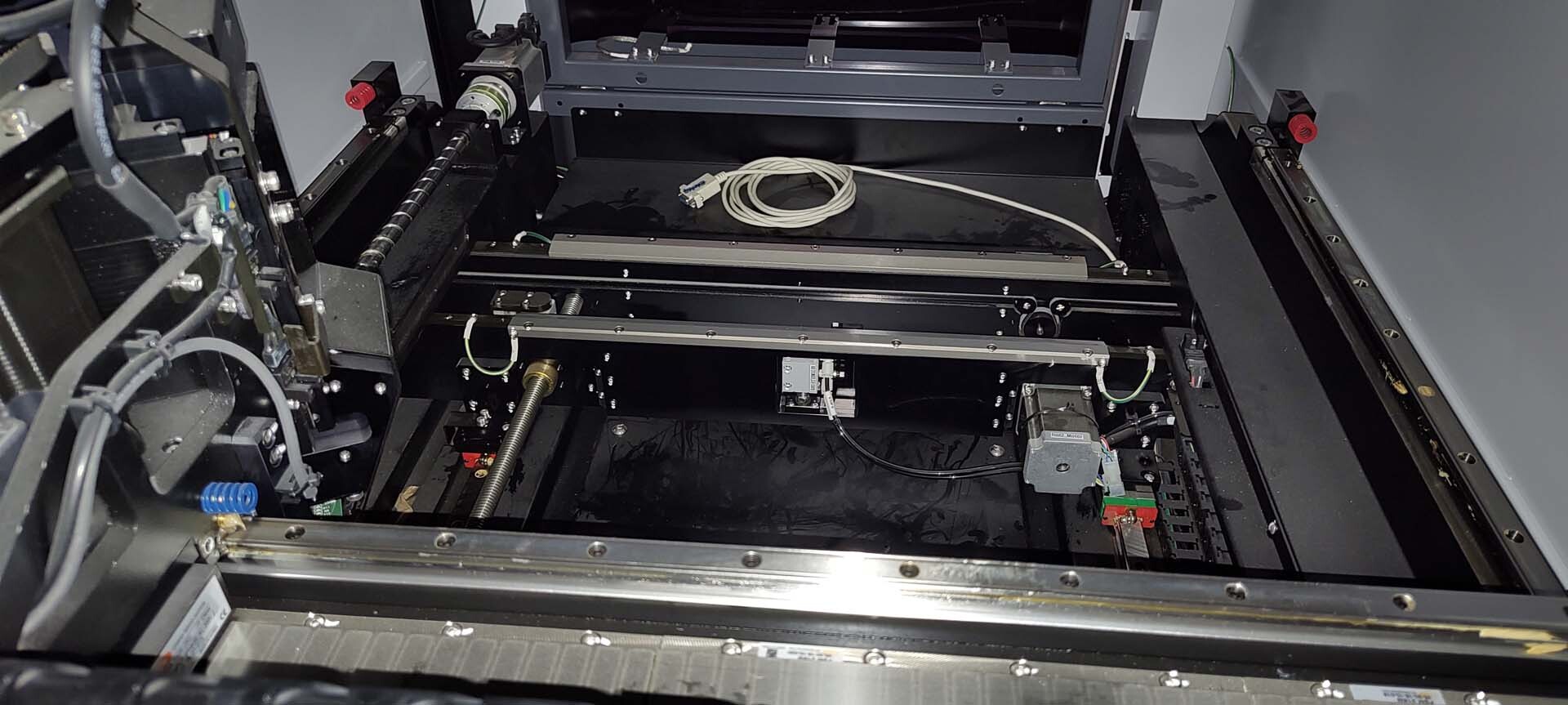

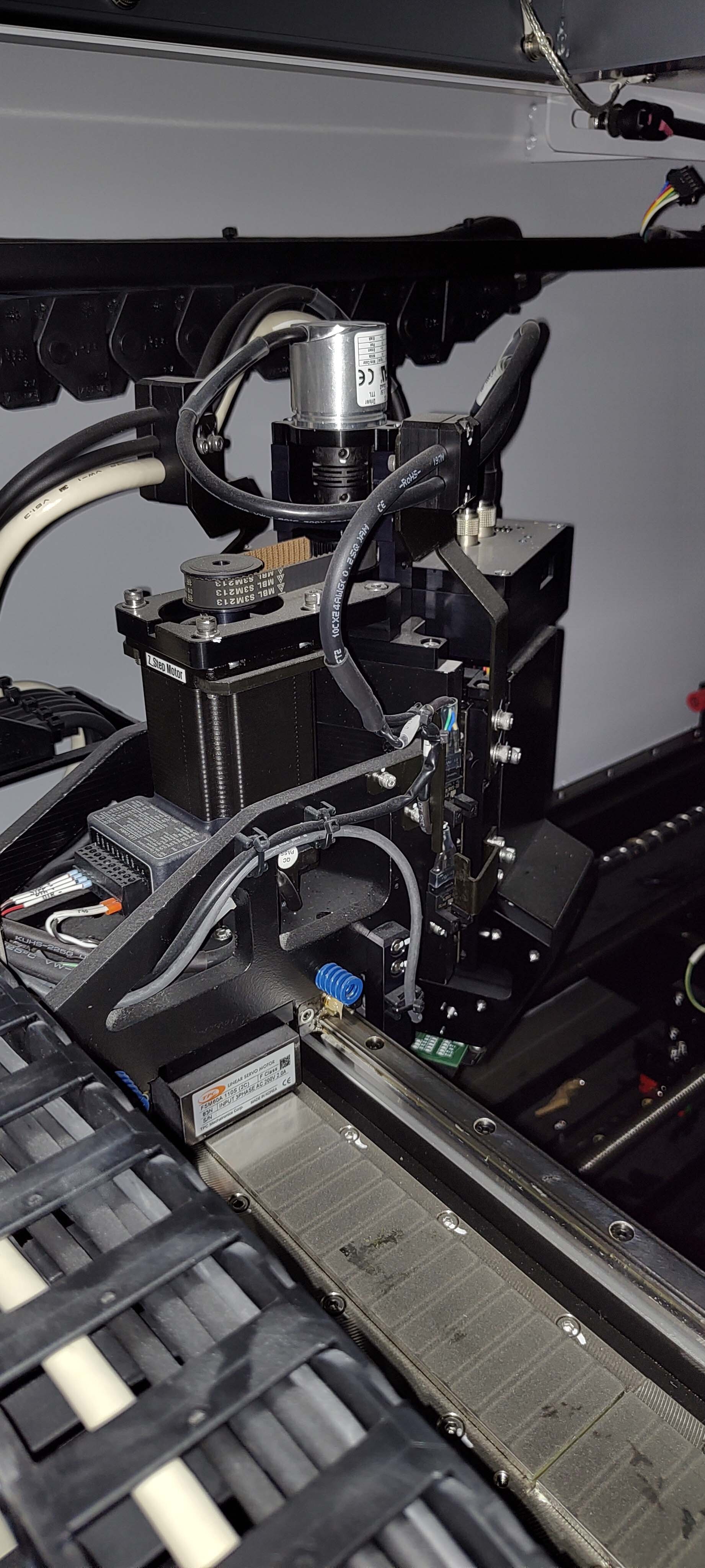

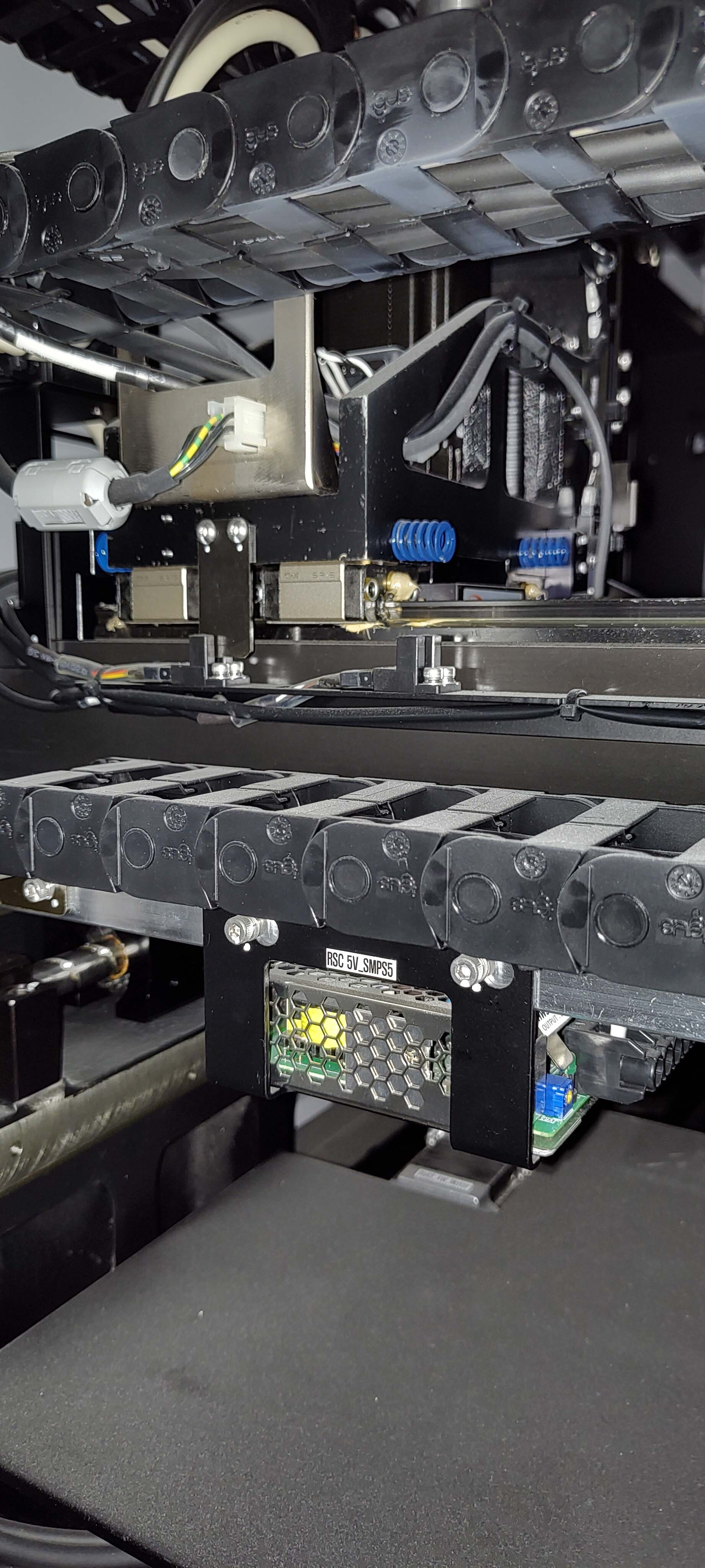

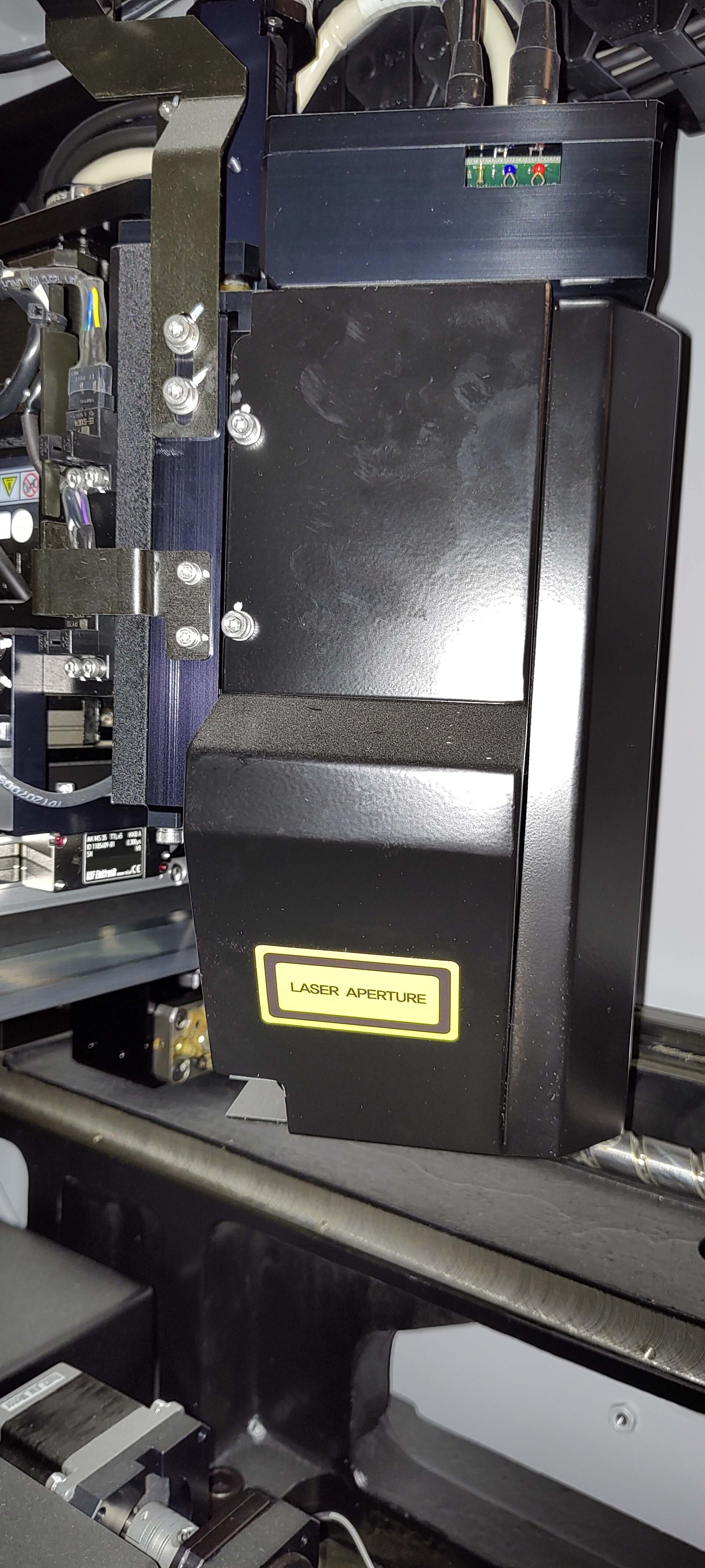

PARMI SIGMA X is an automated pc board assembly and manufacturing equipment that provides automated tools and processes to optimize high-volume, high-mix, and high-complexity customer orders. It offers rapid job programming and setup, eliminates physical programming, and increases the speed of the preparation of customer orders. SIGMA X system includes an integrated machine-vision-based quality control unit that eliminates manual quality inspection. It features a color-coded visual board detection and verification machine, as well as die and component placement accuracy records. This tool also features offline tracking of the number of assembly steps, cycle times, and component consumption on each job. The asset can also utilize a variety of feeder types and is optimized for the setup and operation of multi-process SMT applications. Furthermore, PARMI SIGMA X provides real-time feedback to the operator and enhanced production scheduling. It features automatic board loading with board tracking and support for both linear and rotary pick-and-place heads. The model also offers full traceability, enabling one to follow the board through production and verifying its completion. The equipment offers a wide selection of feeders for components, including matrix trays, cut strip magazines, embossed tape cassettes, AX touch screens, and AX on-screen programming. SIGMA X also provides an automated system for capturing and tracking factory-wide data. This unit captures data from all machines in the production line to provide real-time feedback on production performance and line efficiency. The machine provides a full range of reports, including inventory counts, daily production results, and order expenses. PARMI SIGMA X tool offers an easy-to-use, cost-effective platform for process control and improvement. The asset is strong enough to support production goals, while at the same time providing the tools and processes needed to meet rigorous customer demands. It provides quality assurance and traceability throughout the entire production process, helping customers achieve high levels of repeatability, accuracy, and cost savings in their pc board assembly and manufacturing operations.

There are no reviews yet