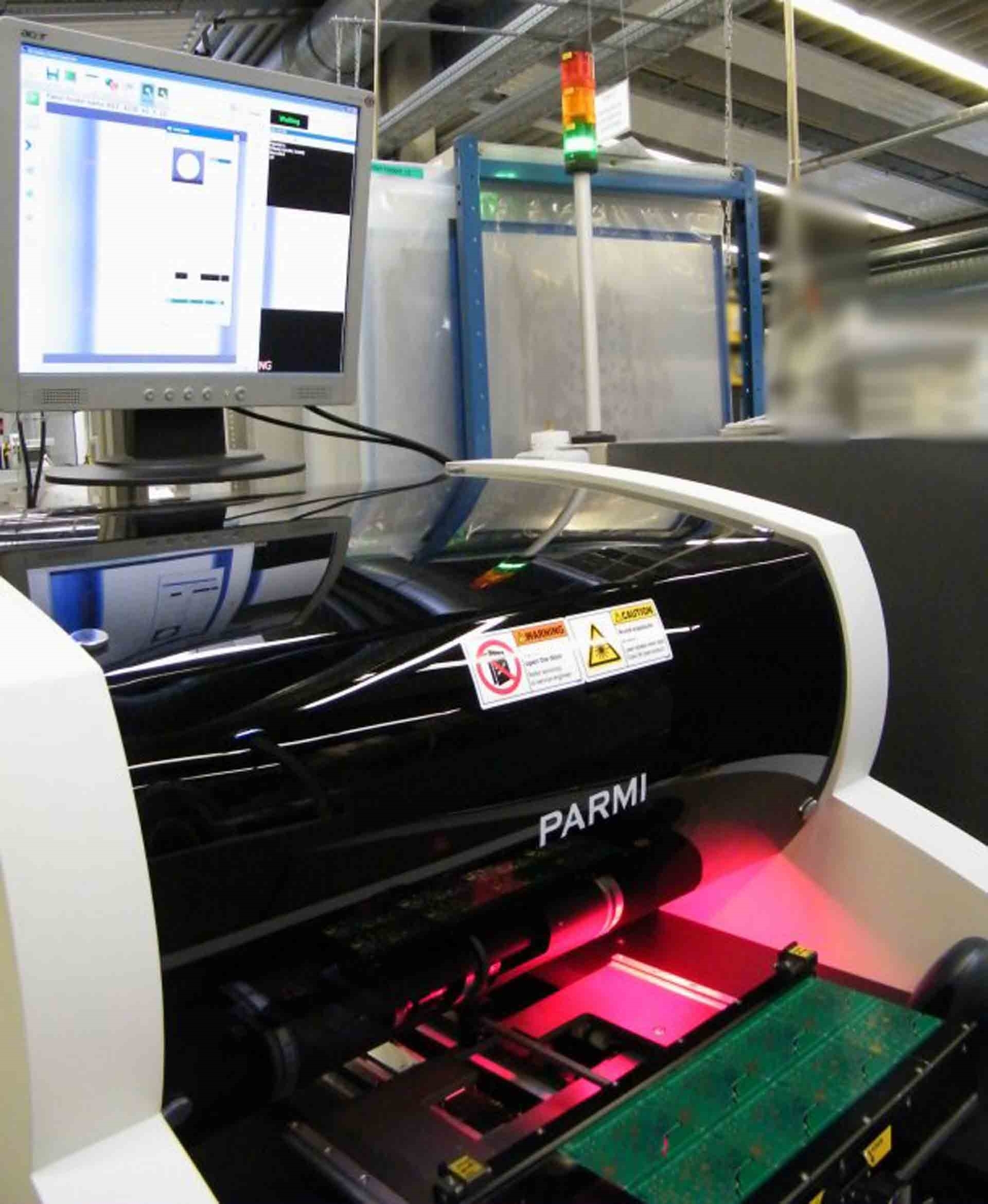

Used PARMI SPI 50T #9240122 for sale

URL successfully copied!

Tap to zoom

ID: 9240122

Solder paste inspection system

Measuring principle: Laser optical triangulation

Camera type: High frame rate C-MOS sensor 18 x 18 um pixel

Resolution:

Scan: 20 µm

Lateral: 18 µm

Height: 0.2 µm

X-Y Robot:

Sensor head in X-axis

PCB Guide unit in Y-axis

Computer: Pentium IV 3.0 GHz

Memory: 2 GB

Operating system: Microsoft Windows XP Professional

LCD Display, 17"

Input: Keyboard & mouse

Voltage: AC 220V

GERBER RS-274X Interface

Barcode: 1D, 2D.

PARMI SPI 50T PC Board Assembly and Manufacturing equipment is designed to perform high-quality assembly and manufacturing of printed circuit boards. It is a high-capacity automatic programming station that supports both direct programming, as well as in-circuit serial programming. SPI 50T system is compatible with multiple programs, such as I2C, SPI, and 1-Wire. It has up to four available programming headers for all programming needs, making it ideal for manufacturing large volumes of PCBs. The unit uses a production-level, high-speed programming process that can handle over 200 units of PCBs per hour. It is designed for high speeds, superior performance and improved safety features, such as a static sensitive technique that prevents static electricity from damaging components. Additionally, the machine features an automatic adjustment function, allowing for faster and more accurate programming. PARMI SPI 50T employs a user-friendly control panel for effortless programming, as well as highly reliable programmable and accurate data transfer. Additionally, the tool has an integrated power supply, eliminating the need for external power sources. The asset is powered by a single-phase AC power supply, and can operate in either manual or automatic mode. The model is equipped with multiple programming heads and is capable of performing a range of functions, such as pre-programming, programming, assembly, and PCB board testing. The programming heads are equipped with a motion controller that allows for productive, optimized programming cycles and improved overall production efficiency. It can support a wide range of programming requirements, such as automation and constant streams of product numbers. The equipment is also capable of programming more than one PCB at the same time, allowing for a more efficient production run. The system also features a dry-ITM module, which provides protection against static electricity, dust and moisture for the printed circuit boards and programmable ICs. SPI 50T PC Board Assembly and Manufacturing systems is designed to provide an efficient and cost-effective solution for manufacturing and programming printed circuit boards. It is perfect for high-production and high-quality requirements, and is able to handle large volumes of programming tasks with a minimum of downtime. The unit gives reliable and consistent performance, and ensures maximum safety for components and programming heads.

There are no reviews yet