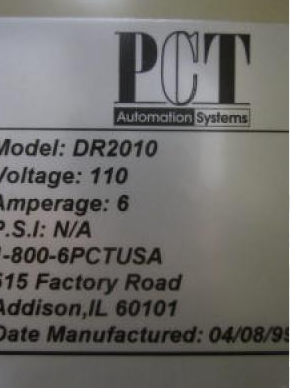

Used PCT DR2010 #163378 for sale

URL successfully copied!

Tap to zoom

ID: 163378

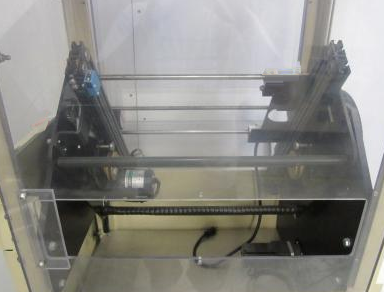

Automation DR2010 Board Flipper

16 inch board capacity

110 volts, 6 amps

~1995 vintage.

PCT DR2010 is a fully automated pc board assembly and manufacturing equipment designed to deliver unparalleled accuracy and precision in manufacturing Printed Circuit Boards (PCBs). The system is integrated into production lines in order to maximize production efficiency and utilize resources such as employees, components and materials. DR2010 includes a conveyor track along which PCBs are transported, enabling a high level of speed and control when moving the boards through each step of the manufacturing process. The conveyor track of the unit, combined with its frame, which supports all the components, ensures a rigid and solid connection between the machine and the PCBs. As the contact is permanent, it ensures that each board is tracked and handled in exactly the same way. The machine also posesses variable speed DC drives to give the precise speed control when needed. The most important component of PCT DR2010 is its vision tool, which is a complete automatic computer vision inspection and part differentiation asset. This helps to identify components on the boards as well as to ensure that every component on a PCB is always placed in the correct position. This ensures that a high level of accuracy is maintained in the manufacturing process. The model automatically checks for any errors on the boards, such as wrong components installation, incorrect polarity or any other faults, allowing them to be corrected before the board is sent for the next step in the manufacturing process. DR2010 also includes a pick & place machine, which is able to pick up components from a bin, place them onto a track and position them accurately onto PALs or other PCBs. The machine is capable of locating components with a precision of 0.005 inches. The pick & place equipment is adjustable, enabling different components and boards to be handled with the same machine. Its robotic arm is also adjustable in order to ensure that components are placed onto a board in the correct positions. PCT DR2010 also includes an intelligent lead bonder, which has the ability to automatically bond lead frames to the board, inspect them properly and provide a wide variety of bond options based on the required parameters. The bonder is adjustable, enabling different components and boards to be handled with the same machine. The system is designed to provide a total solution for pc board assembly and manufacturing. The unit combines all the components mentioned above, with the aim of providing a high level of accuracy and efficiency when it comes to creating PCBs. DR2010 is the ideal machine for businesses that are looking to create high quality, accurate and reliable PCBs.

There are no reviews yet