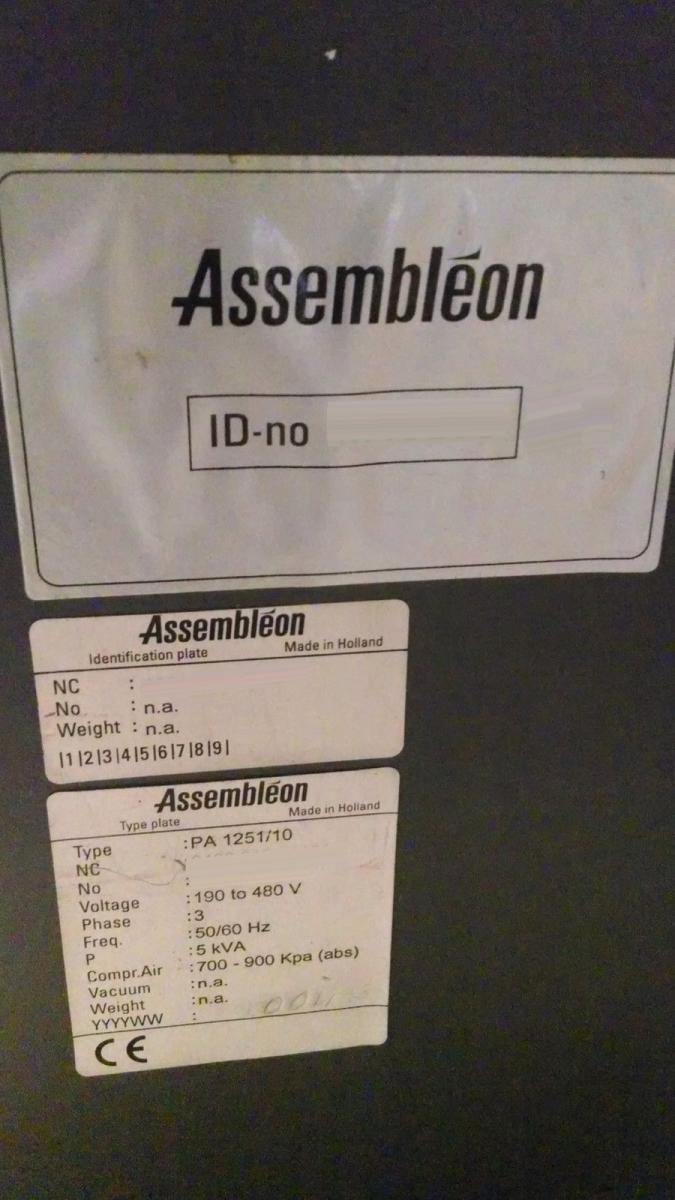

Used PHILIPS / ASSEMBLEON AQ1 #9101908 for sale

URL successfully copied!

Tap to zoom

ID: 9101908

Vintage: 2004

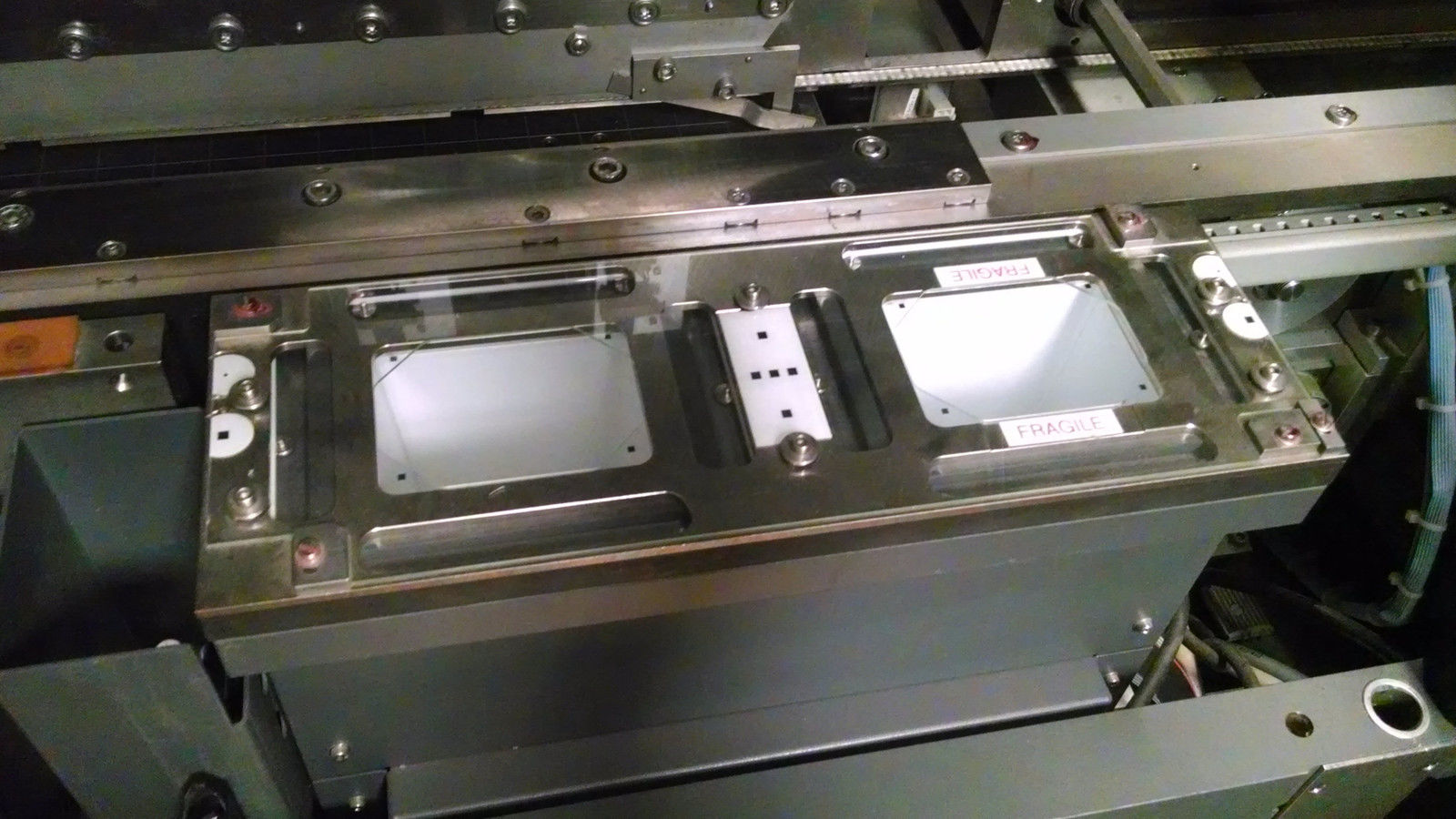

Fine pitch placer

Component range: 0101 - sq44 (or 165x23) mm

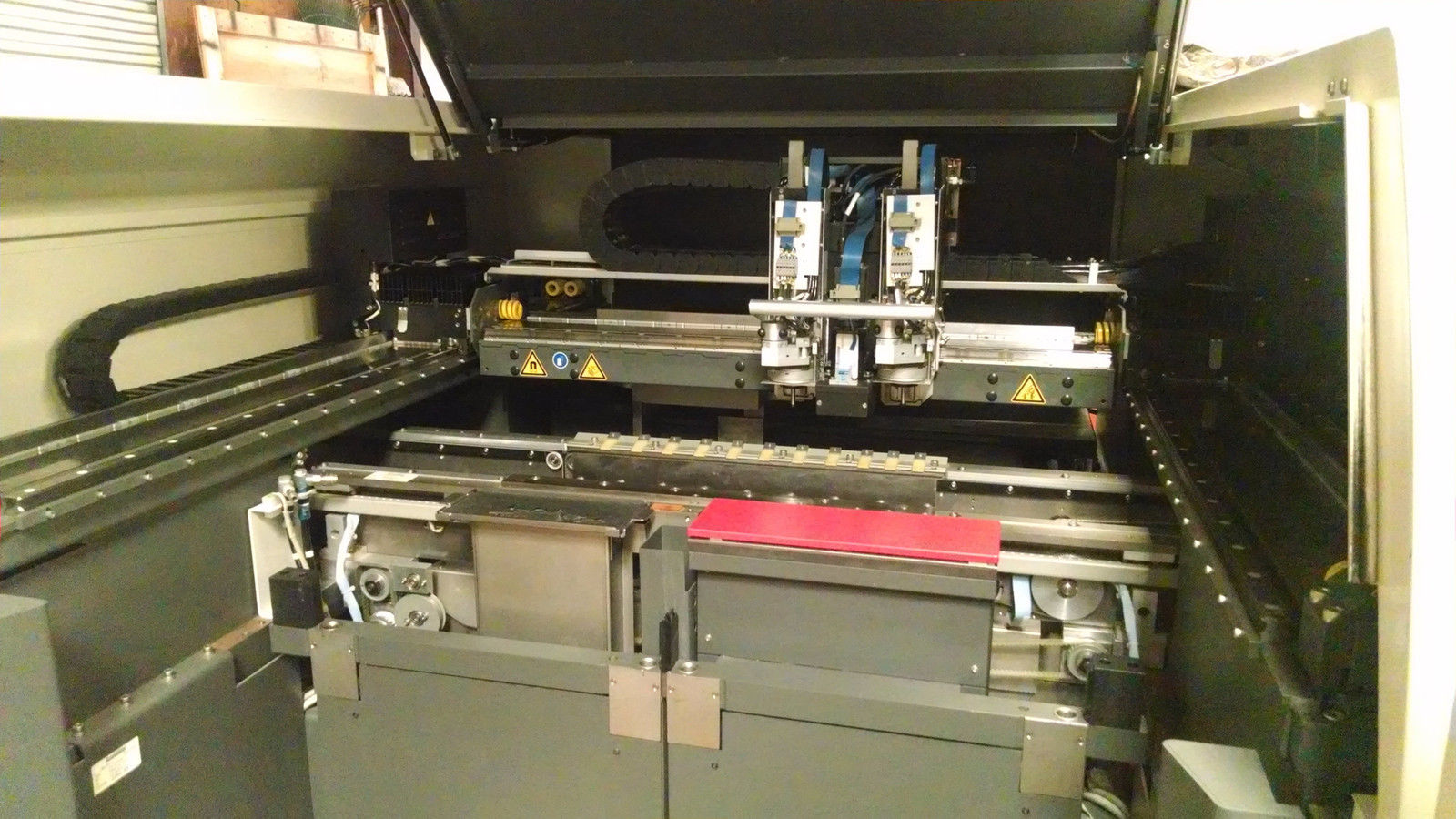

Board size: 50x50 - 460x508mm

Board thickness: 0.3-7mm

Tape feeder slots: 100 (8mm)

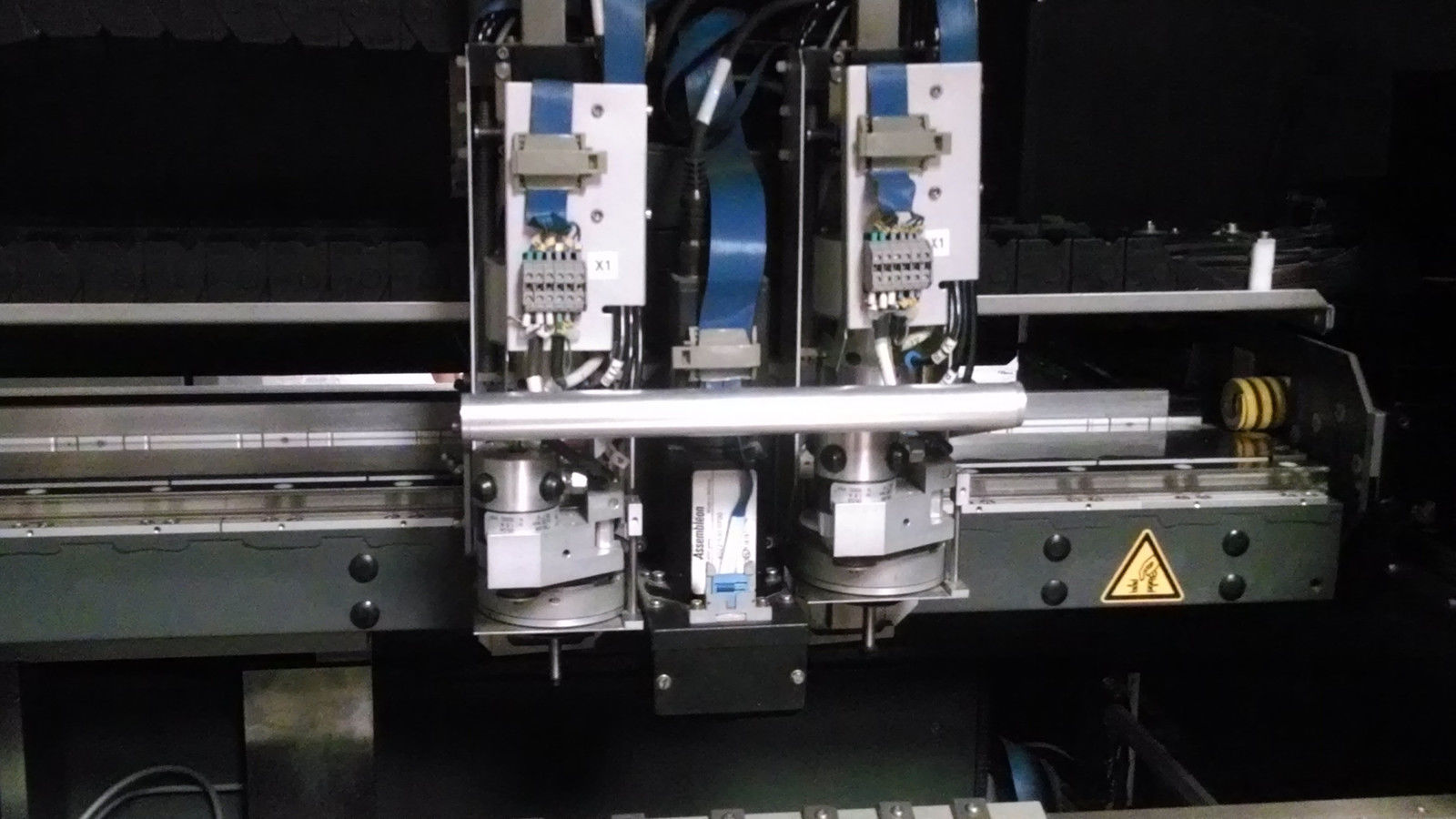

Placement rate: 4,500 (IPC: 3,000) cph

2004 vintage.

PHILIPS / ASSEMBLEON AQ1 is a powerful PC board assembly and manufacturing equipment designed to improve the efficiency and accuracy of the production process. Capable of producing complex designs efficiently, it is an ideal system for mass producing measurable results with minimal downtime. PHILIPS AQ1 is capable of handling processing speeds up to 900 parts per hour, making it a fast and reliable solution for large and small production runs. In addition, its conveyor-mounted Airboard belt unit allows for smooth and accurate positioning of components, ensuring the most efficient assembly process possible. ASSEMBLEON AQ1 features a powerful control machine which includes all the required elements for production automation, including industrial PC, industrial panel, vision tool, printer, board testers, and motors. This asset is designed to provide accurate component placement with optimal repeatability and accuracy. To further enhance accuracy, AQ1 also includes a user-friendly software package, which provides visual feedback and detailed process information. This allows for increased levels of accuracy and feedback on the production status. For the actual manufacturing process, PHILIPS / ASSEMBLEON AQ1 includes several options for both component placement and reflow soldering. Its ModVu fine pitch placement model ensures reliable placement and precise component orientation for accurate assembly. The Fine Pitch equipment is capable of tolerances down to 0.4mm, providing reliable and precise placement of components on the board. Additionally, PHILIPS AQ1 also offers both infrared and vapor phase reflow soldering systems to ensure a seamless production line. Thanks to its production process control, ASSEMBLEON AQ1 provides maximum accuracy and repeatability for both assembly and soldering. Its easy-to-use software package is designed to provide detailed, real-time feedback on the production process, allowing for improved decision-making and product quality control. This powerful system is ideal for both small and medium scale production runs, providing optimal efficiency and repeatability.

There are no reviews yet