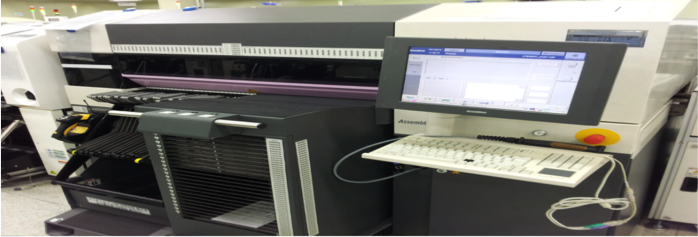

Used PHILIPS / ASSEMBLEON AX201 #9041654 for sale

URL successfully copied!

Tap to zoom

ID: 9041654

Placement machine

Optimal output per hour: 18k

IPC 850 output per hour: 11. k

Placing accuracy at sigma: 20 micron

Component range: 0.4 x 0.2 (01005) to 45 x 45mm/66 x 2 mm, 165 x 2 mm for odd

components (0.016 x 0.008 to 1.7 x 1.7 ”/ 6. x 0. ”)

Maximum component height: 40mm (2”)

Toolbit exchange: automatic nozzle or gripper exchange

Maximum board size: (L x W) 515 x 457mm “)

Minimum board size: (L x W) 50 x 50mm, 50 x 25mm optional

Board thickness: 0. - 6mm

Tape feeding positions (8mm): 212 twin tape, 106 single tape, 76 Jedec

Feeder trolleys: tape feeder trolley, tray trolley, feeder bank

Alignment principle: CCD camera

Placement force: 0. to 40N lower forces possible with restrictions

Communication link: CAMX or SECS/GEM

Footprint (L x W): 1850 x 2240mm incl. trolleys

Single-sided operation: yes (optional double sided)

Running at 220V / 3ph, can be used at 200-480V / 3ph / 47-63Hz

Software: 2013

2007 vintage.

PHILIPS / ASSEMBLEON AX201 is a modern-day PC board assembly and manufacturing equipment designed for high-volume, high-mix production processes in the circuit board assembly industry. It is capable of handling up to two thousand production parts per hour with a fast-switching speed and highly accurate placement accuracy. The system includes a bulk feeder that allows quick loading of boards and components into the assembly area. PHILIPS AX-201 has a dedicated and integrated software platform, combining the functions of line capability and overall control. The software keeps track of all production, control report and stock control, ensuring all components are in the right place and the right quantity at the right time. The throughput monitoring and management unit allows operators to identify, monitor and manage potential throughput risks. The machine also includes a set of advanced assembly technologies, allowing for higher quality and higher throughput at an increased assembly speed. ASSEMBLEON AX 201 can be setup for lead-free assembly, with solder dipping capabilities and modular preheating functions. Its components are designed to be compatible with most existing solder-based assembly processes, allowing for easy transitions. AX 201 also includes a range of connectivity solutions, such as WLAN and RFID, allowing for high speed communication with robots and other assembly systems, as well as remote monitoring of the production process. This allows it to be easily integrated with existing production systems and factories, providing superior connectivity between components and process. PHILIPS / ASSEMBLEON AX 201 is designed for ease of use and operability, so that operators can work productively and quickly. It can be easily setup and maintained with an intuitive graphical user interface, providing operational freedom and control. The tool is designed to minimize production bottlenecks and reduce product lead times. PHILIPS / ASSEMBLEON AX-201 is an efficient and highly accurate board assembly and manufacturing asset, designed to meet the ever-growing demands of the circuit board assembly industry. With its advanced features, it promises superior product quality, faster outputs and increased operability, providing manufacturing and production companies with a reliable and cost-effective solution for the future.

There are no reviews yet