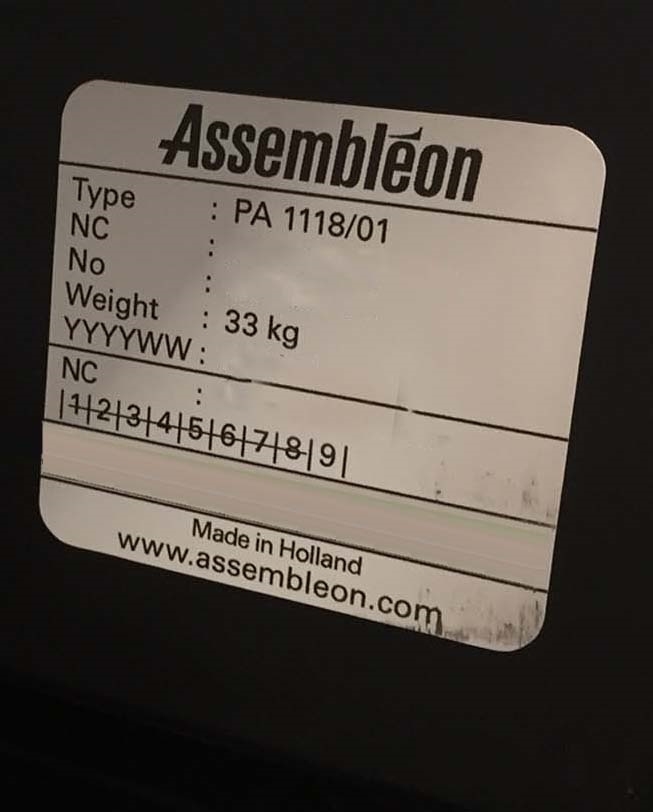

Used PHILIPS / ASSEMBLEON AX301 #9232971 for sale

URL successfully copied!

Tap to zoom

ID: 9232971

Vintage: 2007

Pick and place machine

(10) Robots

60000 cph

2007 vintage.

PHILIPS / ASSEMBLEON AX301 is a state-of-the-art pc board assembly and manufacturing equipment specifically designed to handle the most intricate component placements. PHILIPS AX301 is a high-performance, modular machine capable of operating at speeds up to 40,000 cph, with precision and accuracy that is unmatched in the industry. The machine is built on an innovative platform that provides for alternative process capabilities such as odd-form component placement and automatic optical inspections. ASSEMBLEON AX 301 offers integrated component handling and intelligent feeders that facilitate high throughput. The modular, multi-functional design supports both bottom-side and top-side pick and place for a wide variety of components including 0201s to very large components. The machine is also capable of multiple nozzles to allow split loading of components for higher placements speeds. The advanced equipment control system offers precision motion control and multiple placement programs. The machine is designed with advanced placement technology such as Cognex vision systems and advanced dual camera stereoscopic alignment. Each component is precisely photographed and recognized by the machine to ensure accurate component placement. The intuitive software and intuitive easy-to-use touchscreen interface allows users to quickly configure and control the placement process. The machine also has an integrated barcode scanner for efficient work-in-process tracking. PHILIPS / ASSEMBLEON AX 301 utilizes advanced technologies such as the Access Flexible automated buffer board optimization software. This tool allows users to maximize efficiency by setting up multiple feeders and optimizing cycle time while maintaining peak accuracy for component placement. The built in trouble-shooting unit alerts operators of errors and helps quickly identify and remedy any issues. ASSEMBLEON AX301 also features a modular work platform and custom manufacturing set ups which facilitate optimal product manufacturing performance. The modular platform allows for easy integration of processes such as fiducial recognition, singulation and wave soldering. The machine is also capable of simultaneous bottom-side and top-side soldering, enabling higher accuracy and throughput. The machine also allows for automated component inspection and optional solder paste inspection. Overall, PHILIPS AX 301 pc board assembly and manufacturing tool is a powerful machine that is unmatched in performance, accuracy and reliability. It provides users with an easy-to-use interface, advanced features, and an integrated buffer board optimization software, all designed to maximize efficiency and throughput. The robust machine is ideal for high-volume and intricate pc board assembly and manufacturing operations.

There are no reviews yet