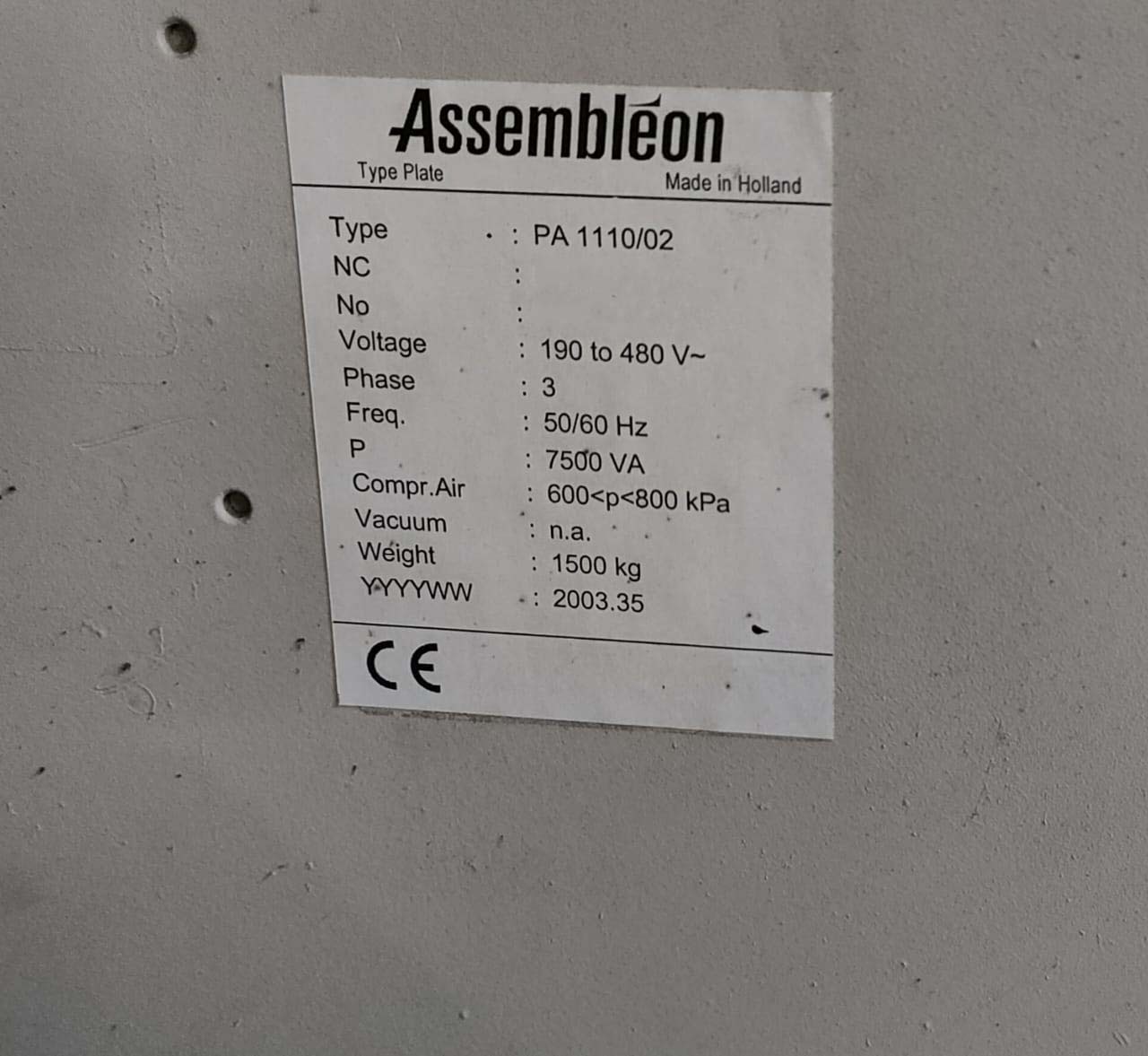

Used PHILIPS / ASSEMBLEON FCM Multiflex #293662940 for sale

URL successfully copied!

Tap to zoom

ID: 293662940

Vintage: 2003

Pick and place machine

(35) Feeders, 8mm

(5) Feeders, 12mm

(20) Nozzles PA 2747/20

(5) Nozzles PA 2747/30

Carrier kit

Carrier adjustment tool

Calibration nozzles

Calibration strips

2003 vintage.

PHILIPS / ASSEMBLEON FCM Multiflex is an advanced pc board assembly and manufacturing equipment designed for high-speed SMT production. The system consists of a suite of tight integrated modules including high-speed pick-and-place, optimised for component placement, as well as BGA, side and edge connector insertion and placement. It also includes a multi-lane, multi-layer conveyor unit for optimal throughput, and automated board handling and storage. High-speed pick-and-place is made possible by the machine's multi-head component feeders with up to 160 positions to hold tape, tube and stick components, and ultra-fast nozzle changers for quick component placement and exchange. The Multiflex also features a patented vision robot which is capable of detecting parts with a 0.038 mm accuracy and providing real-time feedback on camera-based inspection, enabling precise placement of components. The tool can assemble up to 24,000 components per hour, and is equipped with advanced programming software for fast and accurate component placement. The multiflex also features a high-precision placement accuracy of +/- 0.1 mm. In addition, the asset can handle a wide variety of components including 01005 size chips, LF-BGA leadless packages, through-hole components, connectors, and odd-form parts. The Multiflex is also designed for easy maintenance and is fitted with user-friendly software that allows for an efficient setup process and flexible programming. The Multiflex can be used for a variety of applications including single- and double-sided, multi-layer boards. The model also features specialty functions such as component side printing, glue dispensing, and other customized programming functions to ensure a reliable and high quality production process. In addition to the advanced assembly and manufacturing capabilities, the Multiflex also offers stringent quality control measures, including automated optical inspection and in-process testing, ensuring a defect-free manufacturing process. Finally, the equipment is built in line with the latest safety standards, and is designed for easy integration with other devices and machines to create a complete production line. Overall, PHILIPS FCM Multiflex is a powerful and reliable pc board assembly and manufacturing system that offers a comprehensive range of advanced features to ensure precise, defect-free production. With its high throughput, flexible programming, and stringent quality control, the Multiflex is the perfect solution for any high-volume production needs.

There are no reviews yet