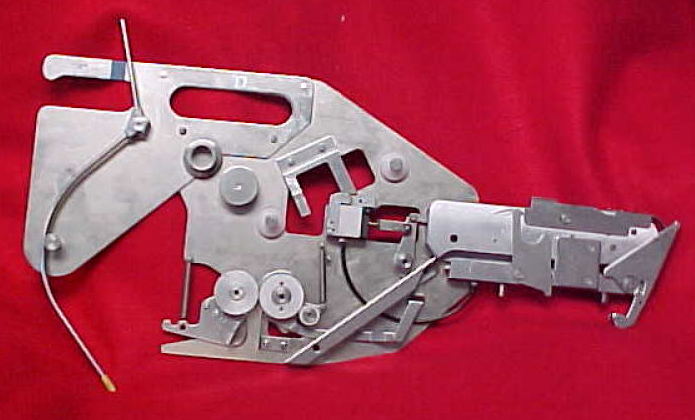

Used PHILIPS / ASSEMBLEON GEM #161289 for sale

URL successfully copied!

Tap to zoom

ID: 161289

Tape Feeders:

(40) 8mm PA 2903/71

(3) 12mm PA 2903/80

(2) 16mm PA 2903/20

24mm PA 2903/30.

PHILIPS / ASSEMBLEON GEM (Global Equipment Manufacturing) is a comprehensive suite of production and assembly tools for Printed Circuit Board (PCB) and SMT manufacturers. This equipment is designed to streamline the manufacturing process and reduce the number of steps needed to complete the job. PHILIPS GEM system consists of software, hardware, and various automated tools and components. The software, known as PHILIPS Manufacturing Platform, utilizes a Modular Component Library (MCL) that allows for easier customization and maintenance of the unit. This library supports a range of production and assembly related tasks like synchronization, data flow management, defect handling, and more. The hardware, known as ASSEMBLEON Factory Automation Machine, is the backbone of the tool. It is interfaced with the software and relies on sensors, servo motors, and PLCs to control the production, assembly, and testing processes. By utilizing this automation technology, ASSEMBLEON GEM asset is able to drastically reduce down time and optimize production speeds. GEM model utilizes a range of automated tools and components customized to fit the needs of a particular project. This includes In-Circuit testers, AOI (Automatic Optical Inspection) machines, surface mount pick-and-place machines, wave soldering machines, and reflow ovens. These tools are used to produce and assemble PCBs with optimal efficiency and accuracy. The software platform also comes with a slew of reporting and tracking systems for monitoring production, assembly, and testing processes. This ensures seamless management of resources, provides real-time feedback, and collects valuable data for future use. Overall, PHILIPS / ASSEMBLEON GEM is capable of streamlining the entire production and assembly process of PCBs and SMT components. It's comprehensive suite of software, hardware, and tools are outfitted with advanced automation and tracking systems, making it one of the most technologically advanced and efficient production and assembly systems available.

There are no reviews yet