Used PHILIPS / ASSEMBLEON Opal XII #293604362 for sale

URL successfully copied!

Tap to zoom

ID: 293604362

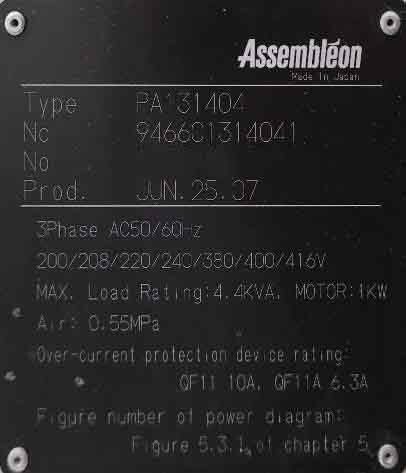

Vintage: 2007

Pick and place machine

Running hours: 9158

2007 vintage.

PHILIPS / ASSEMBLEON Opal XII is a high-speed, automated pc board assembly and manufacturing equipment. This system is designed to assist pc board fabricators in meeting their demands for high-volume, high-quality assembly. PHILIPS OPAL-XII offers a broad production range that is suitable for any fabricator's needs, from high-level assembling to fine-tuned sub-assemblies. The unit is capable of handling through-hole, surface mount, ball-grid array, bumped devices, and chip scale packages. The machine also supports flip-chip placement and place-and-reflow techniques. The tool is designed with a modular layout that allows machines to be added to grow production needs. Additionally, the machine uses a multi-magazine supply asset, allowing the use of multiple reel feeders and tray feeders on the same feeder type. This increases operational efficiency and throughput. ASSEMBLEON OPAL X II is equipped with a state-of-the-art user interface, featuring a graphical robot control model, which simplifies programming and operation. This user interface can also integrate with external databases for item tracking, process control, and operator-friendly programming. The equipment is powered by an internal computer that is programmed to complete tasks quickly and accurately. It is equipped with color cameras and advanced image processing capabilities that enable fast, precise placements. Additionally, it has the ability to perform real-time PCB inspections. Furthermore, PHILIPS / ASSEMBLEON OPAL X II is designed to keep up with the busy production schedules and handle high volumes of orders. Its flexible control system can be configured to meet customer specifications, allowing it to be customized for a company's unique production needs. The unit comes with an array of features that are essential for flawless production. Its automatic tooling machine eliminates the need for manual tooling changes, reducing production errors. The tool also features a self-diagnostic capability that automatically detects problems and sends reports to the maintenance crew. OPAL X II provides fabricators with the power and flexibility needed to meet their production needs. The asset has the capability to quickly handle high production volumes and is equipped with a multitude of features that ensure accuracy and efficiency. The user-friendly interface allows for easy programming, increasing production speed and reducing production errors.

There are no reviews yet