Used PHILIPS / ASSEMBLEON Opal XII #9174727 for sale

URL successfully copied!

Tap to zoom

ID: 9174727

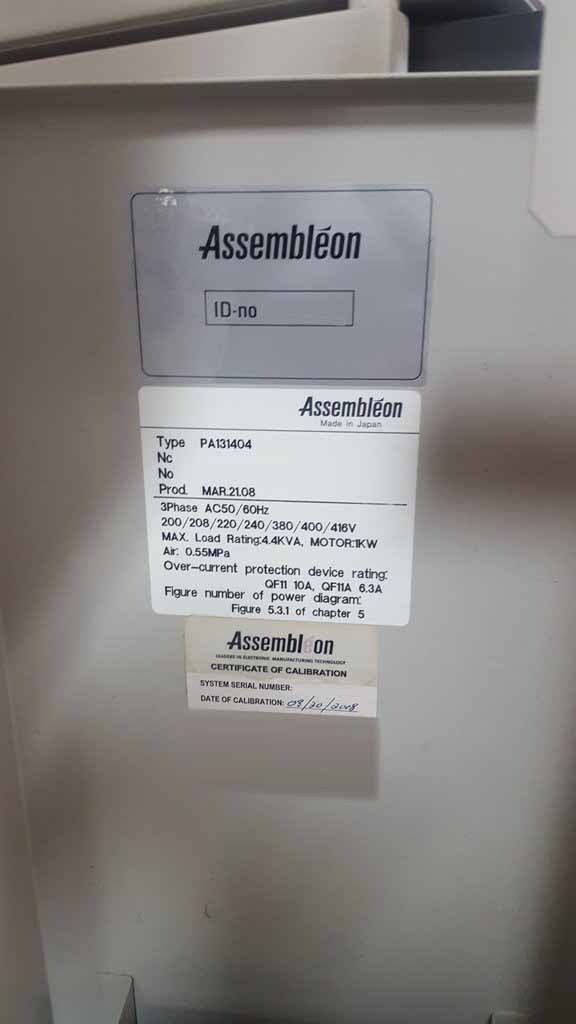

Vintage: 2008

Pick and place machine

01005 BGA

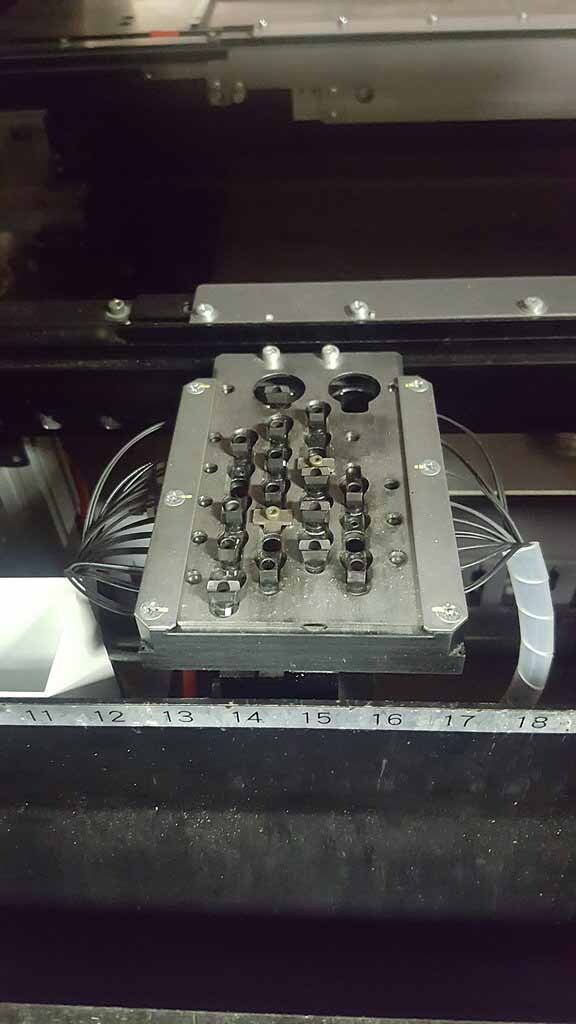

(8) SF Heads

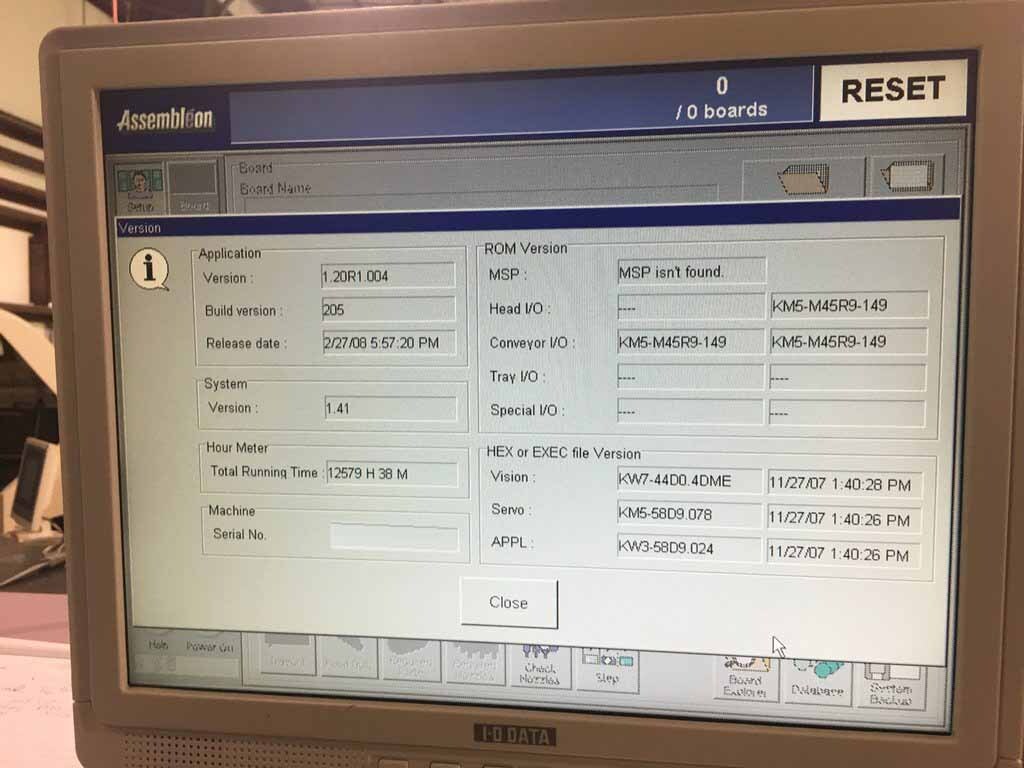

Hours: 12500

CPH: 15400

Max part height: 7 mm

Fine-pitch QFP

BGA

μBGA

CSP Packages

(40) Feeders package:

(32) 8x4 mm

(5) 12 mm

(2) 16 mm

(1) 24 mm

Technical specifications:

Optimal output per hour: 17.7 with (8) heads

IPC 9850 Output per hour: 13.8 with (8) heads

Head design with SF:

One single beam with (8) super fine heads

Placing accuracy at 3 sigma:

(50) Microns for chips

(40) Microns for QFP's

Component range: 01005 (0402) to 45 x 100mm (BGA, µBGA. CSP, Connector, Odds)

Maximum component height: 11mm (0.4")

Tool bit exchange: Automatic nozzle or gripper exchange

Maximum board size (L x W): 460 x 440 mm (18.1 x 17.3")

Minimum board size (L x W): 50 x 50 mm (2 x 2")

Large board application: 650 x 850 mm (25.6 x 33.5")

Board thickness: 0.4 to 4.0 mm (0.016 x 0.16")

Tape feeder positions (8mm): 100 (CLi)

Feeder options: Tape, stick, tray, tube, etc

Alignment principle: Line array camera

Footprint (L x W): 1650 x 1408 mm (5.4 x 4.5 ft)

Operating system: Windows NT

2008 vintage.

PHILIPS / ASSEMBLEON Opal XII is a PC board assembly and manufacturing equipment designed for high-volume production. It comes with a choice of different pick-and-place heads, optimized for speed and accuracy to ensure the highest quality soldering and accurate dispensing of components and soldering paste. PHILIPS OPAL-XII can place components ranging in size from 0201 chips to ultra-thin QFNs up to 23.5mm². With its wide component range, it can easily handle high-mix, low-volume production runs. ASSEMBLEON OPAL X II is designed with flexibility in mind, featuring a fully adjustable work area suitable for boards up to 510mm x 510mm. A mini-slot feeder interface allows for the placement of small components on tape and strip. The system also features unlimited dual lane capability, allowing two simultaneous board movement for improved throughput. Thanks to an intelligent vision recognition unit and sophisticated inspection routines, ASSEMBLEON OPAL-XII offers reliable performance in even the most rigorous production environments. PHILIPS OPAL X II is equipped with a high-performance, low-maintenance conveyor that is designed to offer consistent repeatable movement. The machine is completed by a variety of thermal and vision based inspection options that identify potential flaws before the completed boards leave the production line. PHILIPS Opal XII also features a comprehensive software suite designed to reduce setup and programming times. The integrated auto-design, auto-programming and auto-verification functions speed up production while minimizing human error. Automated data logging and reporting functions track production performance, resulting in improved process optimization. Overall, PHILIPS / ASSEMBLEON OPAL-XII is an advanced PC board assembly and manufacturing tool designed for the most demanding production runs. With its fully adjustable work area, unlimited dual lane capability, comprehensive software suite, and powerful inspection features, ASSEMBLEON Opal XII is an indispensable tool in any PCB assembly and manufacturing process.

There are no reviews yet