Used PHILIPS / ASSEMBLEON Topaz XI #9077571 for sale

URL successfully copied!

Tap to zoom

ID: 9077571

Pick and place machine

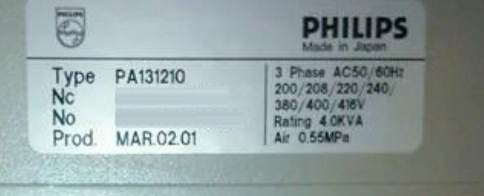

Model No.: PA131210

(38) Feeders:

(33) 8 x 4mm

(3) 12 x 8mm

(1) 16 x 8mm

(1) 12 x 4mm

2001 vintage.

PHILIPS / ASSEMBLEON Topaz XI is a multifunctional PC board assembly and manufacturing equipment that offers a highly customizable system for high-volume production of PC boards. The unit includes fully integrated components such as an intelligent feeding machine, a powerful vision-image guided processor, and the latest in robotic automation technology. These components work in unison to realize efficient production line throughput and ensure high-quality fabrication results. PHILIPS Topaz XI utilizes a smart vision-guided processor for accurate part identification and placement on the line. This processor utilizes innovative algorithms to identify components and efficiently locate them on the board. The resulting high accuracy in placement contributes significantly to the overall performance of ASSEMBLEON Topaz XI. In addition to vision-guided technology, the tool also incorporates robotic automation systems to aid in part placement and corrective action. The configuration of the robotic arm and its overall range of motion takes into consideration the entire process in order to maximize board production efficiency. The asset also includes an intelligent feeding model that produces its own feeder tapes. This feature provides increased flexibility and shortens the process cycle time, resulting in faster runs without sacrificing quality. Topaz XI also boasts a powerful software for programming, manual teaching, and operation control. The user-friendly interface and real-time debugging features make programming complex parts and components simpler and more efficient, resulting in improved production time and cost reduction. Overall, PHILIPS / ASSEMBLEON Topaz XI provides an advanced, but reliable manufacturing equipment to meet the demands of high-volume PC board production. The integration of robotic automation, intelligent vision-image guided processor, and smart feeding system ensures efficient and accurate workflow that maximizes production line throughput. The latest programming software further simplifies the entire process, resulting in an improved bottom line without compromising the quality of the fabrication.

There are no reviews yet