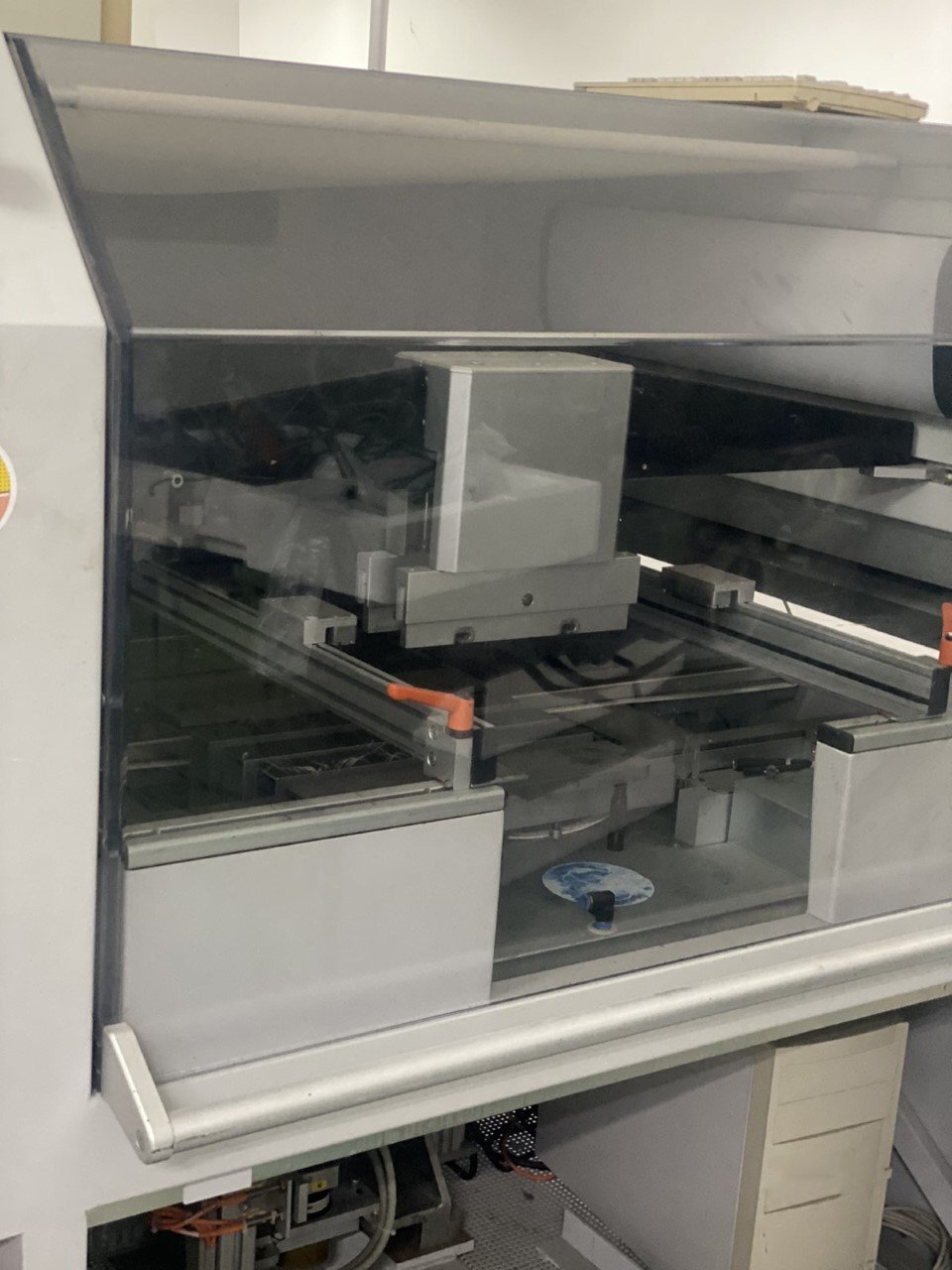

Used PHILIPS / ASSEMBLEON Topaz XII #9244239 for sale

URL successfully copied!

Tap to zoom

ID: 9244239

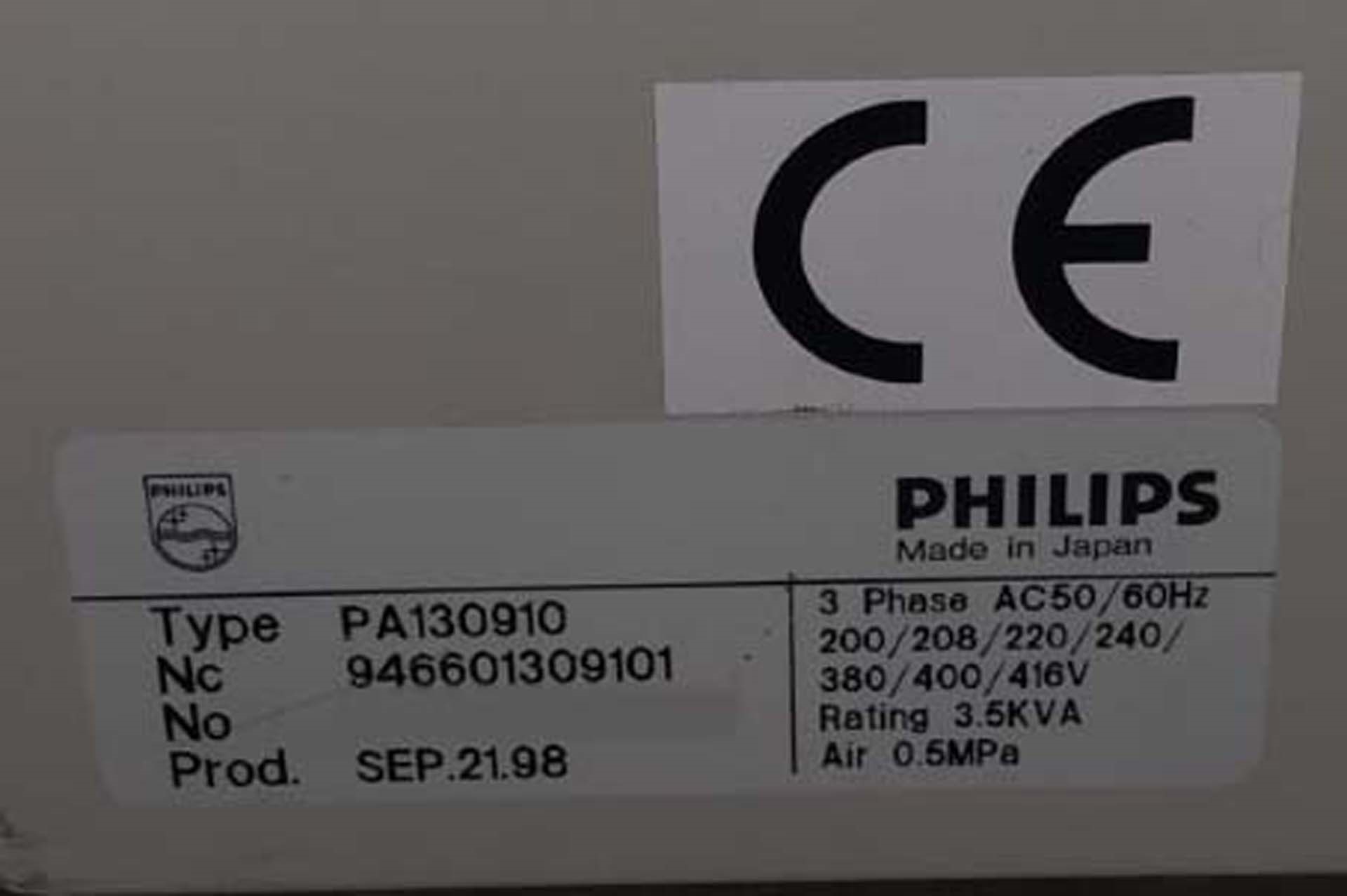

Vintage: 1998

Pick and place machine

Eclipse II

Printer

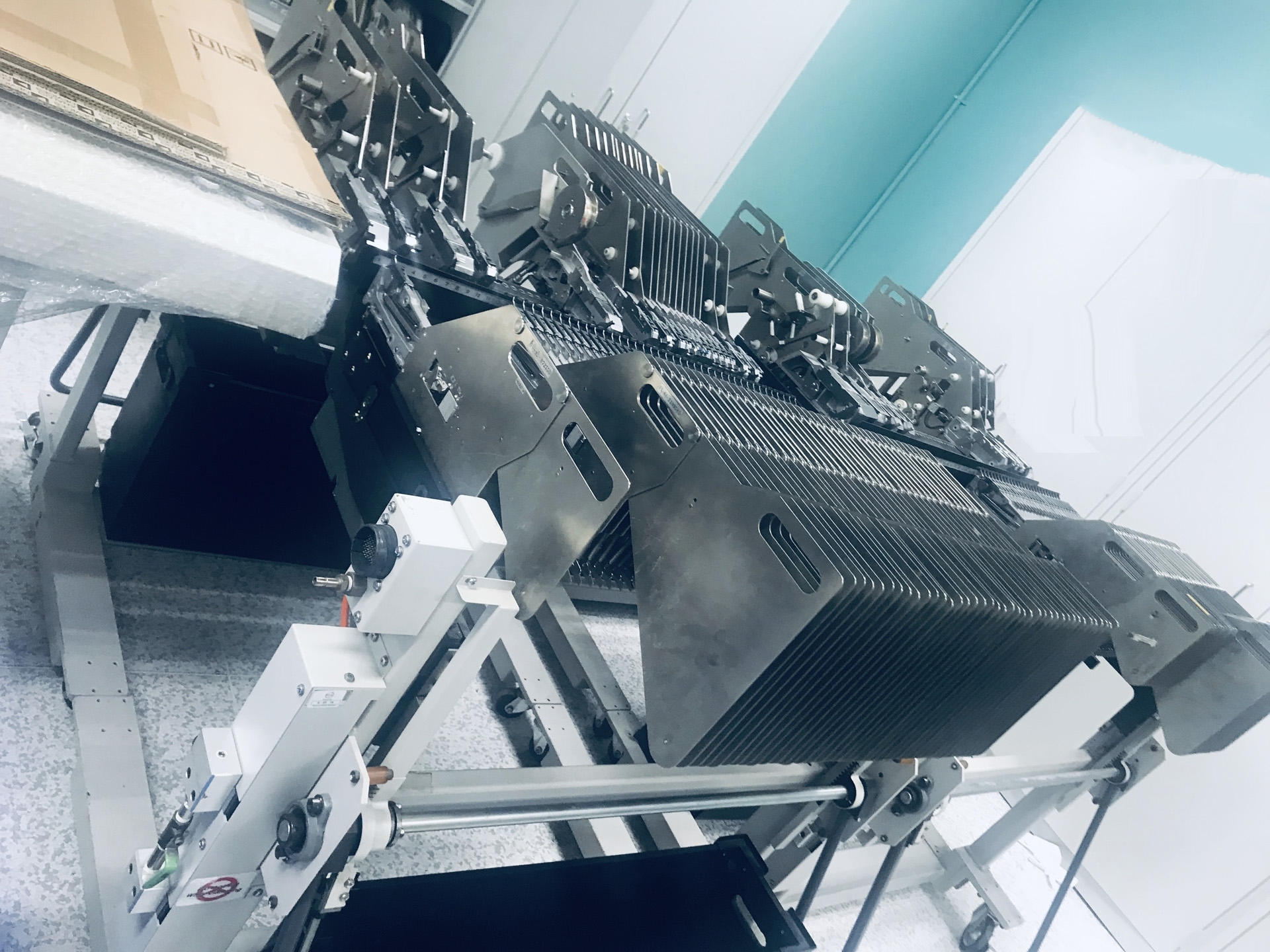

(150) Feeders

1998 vintage.

PHILIPS / ASSEMBLEON Topaz XII is a next-generation "PC Board" assembly and manufacturing equipment designed to provide scalable, advanced productivity and flexibility through its advanced modular architecture. The system features plug-and-play modules, making it simple to integrate into existing production environments. The modular tray permit various board sizes and larger parts to be accommodated with ease. Traversing speeds have been significantly increased with the introduction of intelligent servos. The smart feeders are now powered by the PACE software module, leading to greatly improved feeder performance, faster setup times and improved throughout. PHILIPS TOPAZ-XII incorporates a 3-axis gantry robot, making it easier and more efficient to pick and place components onto and from boards. Component recognition is vastly improved through the use of advanced CMOS imaging and optical sensors. The unit can also easily be integrated with AOI, X-Ray or SPI systems for complete automated optimization on the factory floor. The onboard diagnostic module allows users to monitor and analyse machine performance more accurately, allowing for faster troubleshooting and improved productivity. The open machine platform also allows for integration of further software applications, pushing the integration of data between the machine and host tool. Host asset support includes OPC, SECS/GEM and SMEMA standards. ASSEMBLEON TOPAZ X II is also available as a "true" double station machine, with both placements heads working independently to double output per cycle. This option allows efficient throughput for manufacturers dealing with high mix production. Overall, ASSEMBLEON TOPAZ-XII provides advanced manufacturing solutions for an ever-changing production environment. Its modularity, open software platform and efficient design make it suitable for a wide array of production conditions, increasing throughput, cost-efficiency and yielding improved quality.

There are no reviews yet