Used PHILIPS / ASSEMBLEON Topaz XII #9354510 for sale

URL successfully copied!

Tap to zoom

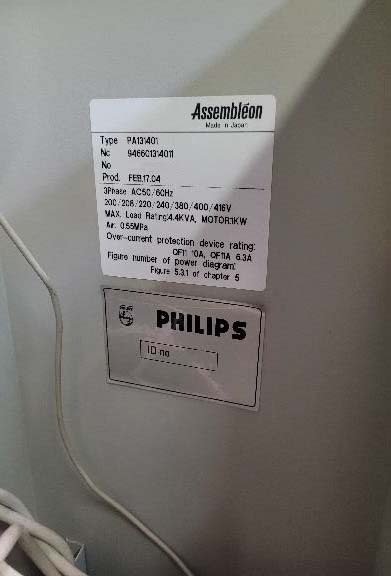

PHILIPS / ASSEMBLEON Topaz XII is a high-speed, flexible and modular pc board assembly and manufacturing equipment which provides an efficient and cost-effective solution for medium to high-volume production output. The system is comprised of two main major components, PHILIPS TOPAZ-XII conveyor and ASSEMBLEON TOPAZ X II pick & place machine. PHILIPS TOPAZ X II conveyor is a Y-channel type feeder which provides high-speed feeds from the in-feed area to the output area. It is equipped with access cover and an integrated vision unit which enable efficient inspection and optimization of board for defects during the production process. This feeder is capable of handling pc board up to 1200mm x 1600mm in size. The conveyor is also capable of handling two-sided boards that are up to 7.4mm in thickness and up to 35kg in weight. ASSEMBLEON Topaz XII pick & place machine is a highly precise, high-speed machine that is capable of placing components to exact locations accurately and quickly. It is equipped with four control boards and two pumpers, which each of them is capable of operating independently depending on the product requirements and also allowing higher component placement accuracy and providing higher top speeds. The pick-and-place machine is fitted with an 8-port nozzle changer and two nozzle racks, allowing up to eight different nozzle sizes to be used for different products. The machine is also equipped with a vision machine and 6D inspection which can perform inspection of critical components such as connectors, sockets, resistors, and capacitors ensuring the proper placement of components and eliminating product defects. The tool has an advanced user-friendly interface based on Windows for easy adjustment of parameters and asset control. TOPAZ-XII has a maximum acceleration of 1G and is capable of placing components at up to 58,000 components per hour with a placement accuracy of +/- 0.02mm. The model also has an auto-alignment capability with a measurement accuracy of 0.1° which ensures correct positioning and consistent accuracy. The equipment further reduces total product production costs and cycle times by reducing repair and reworks processes, eliminating the need for manual inspections and removing the need for any additional resource-consuming activities.

There are no reviews yet