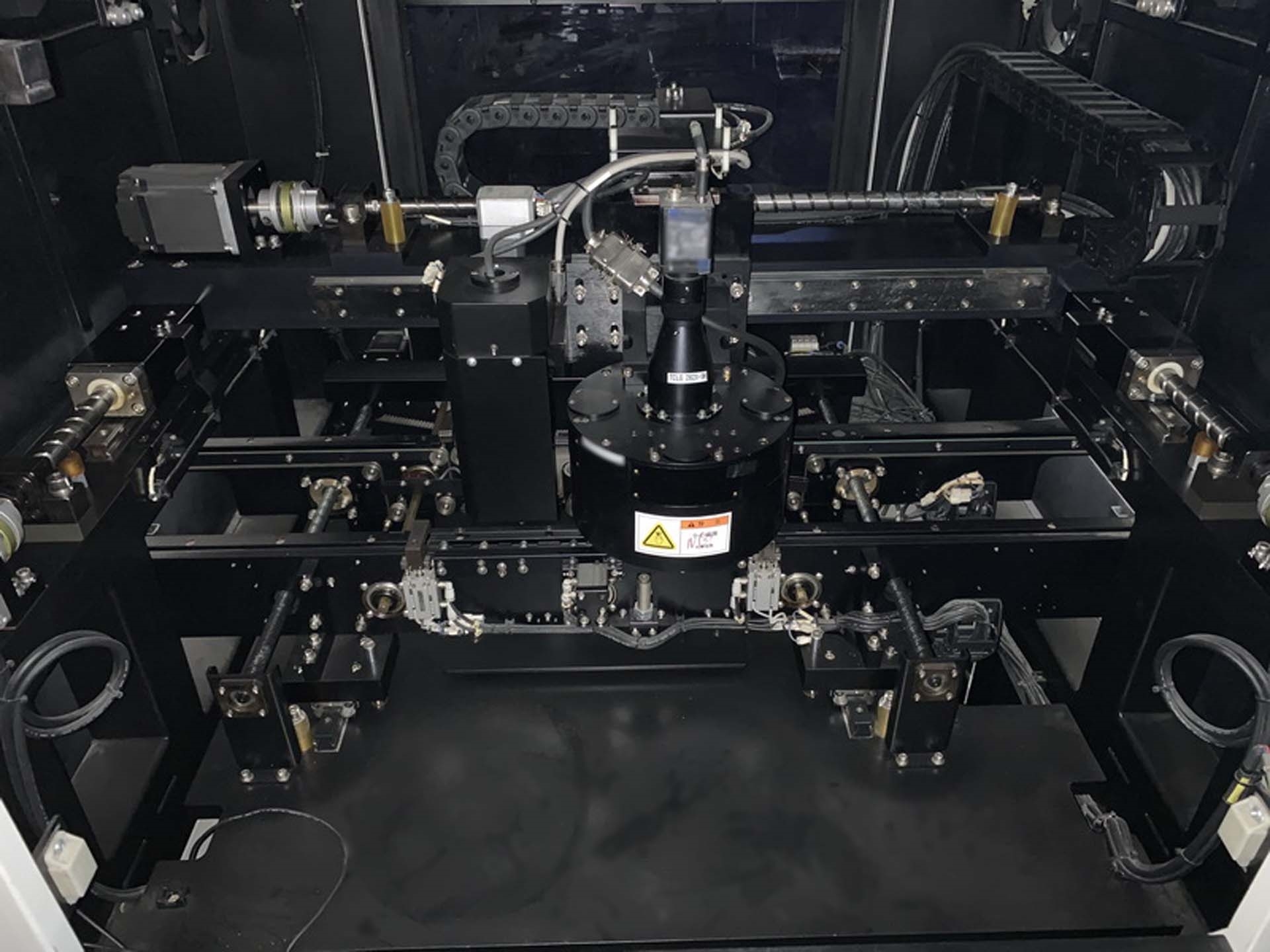

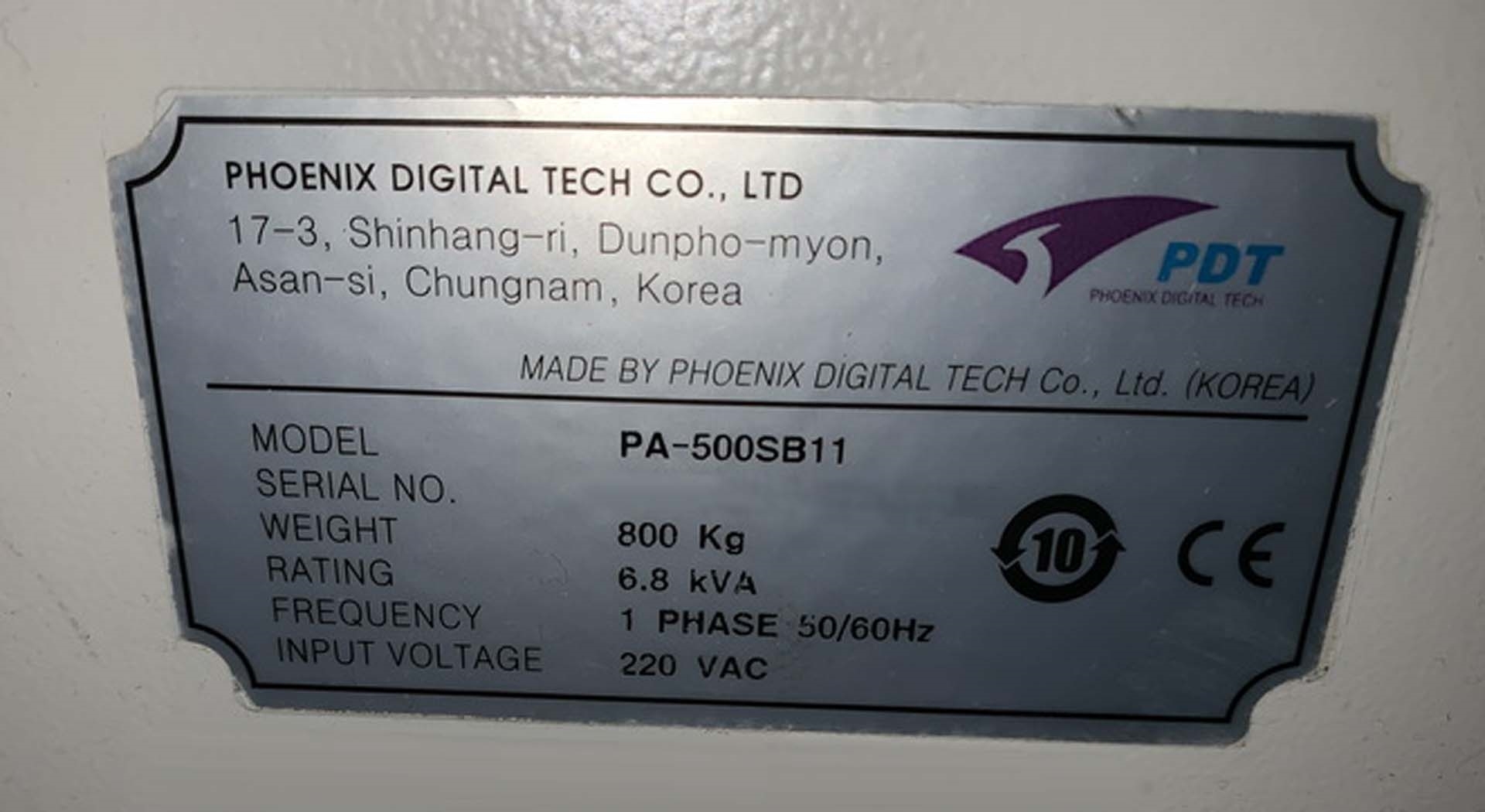

Used PHOENIX PA-500SB11 #9244902 for sale

URL successfully copied!

Tap to zoom

PHOENIX PA-500SB11 is an innovative, advanced equipment for pc board assembly and manufacturing, developed by PHOENIX Electronics. It is designed to increase production efficiency and reduce overhead costs in the production process. This system provides a high degree of automation, while still allowing users to customize components to their own production processes. Designed with a modular approach, the unit can easily scale to meet any manufacturer's specific requirements. The main component of PA-500SB11 is its sophisticated motion control machine, providing superior accuracy while also minimizing downtime due to maintenance. This tool allows users to make precise adjustments to the speed and acceleration of the machine, and includes safeguards that protect against unexpected movements. The included control board provides all the necessary signals for production, monitor machine functions, as well as monitor asset data. In addition, PHOENIX PA-500SB11 comes with a comprehensive range of components, tools, and accessories that are designed to streamline the production process. The model is capable of assembling various types of components including connectors, capacitors, resistors, diodes, and transistor modules. It also comes with an array of production tools, such as pick-and-place tools, check loaders, and test mode controllers. The equipment also includes ancillary components such as a conveyor belt, vacuum cleaner, and microprocessor for efficient production of PCBs. PA-500SB11 comes with a wide range of advanced features to facilitate efficient operation and minimize downtime. The system features automated error detection and diagnostics, which make it possible to identify issues with components quickly, allowing issues to be rectified without wasting valuable production time. Additionally, the unit features a sensing machine that can detect faults with the production process and can be programmed for specific functions. This reduces the chance of costly mechanical faults going undetected. In conclusion, PHOENIX PA-500SB11 is a highly advanced PC board assembly and manufacturing tool that is designed to increase production efficiency while simultaneously minimizing production costs and maintenance time. The asset contains a comprehensive range of components, tools, and accessories that are designed to streamline the production process, as well as advanced features such as automated error detection and sensing systems. This makes PA-500SB11 the perfect choice for any manufacturer looking for a reliable, efficient, and cost-effective model for pc board assembly and manufacturing.

There are no reviews yet