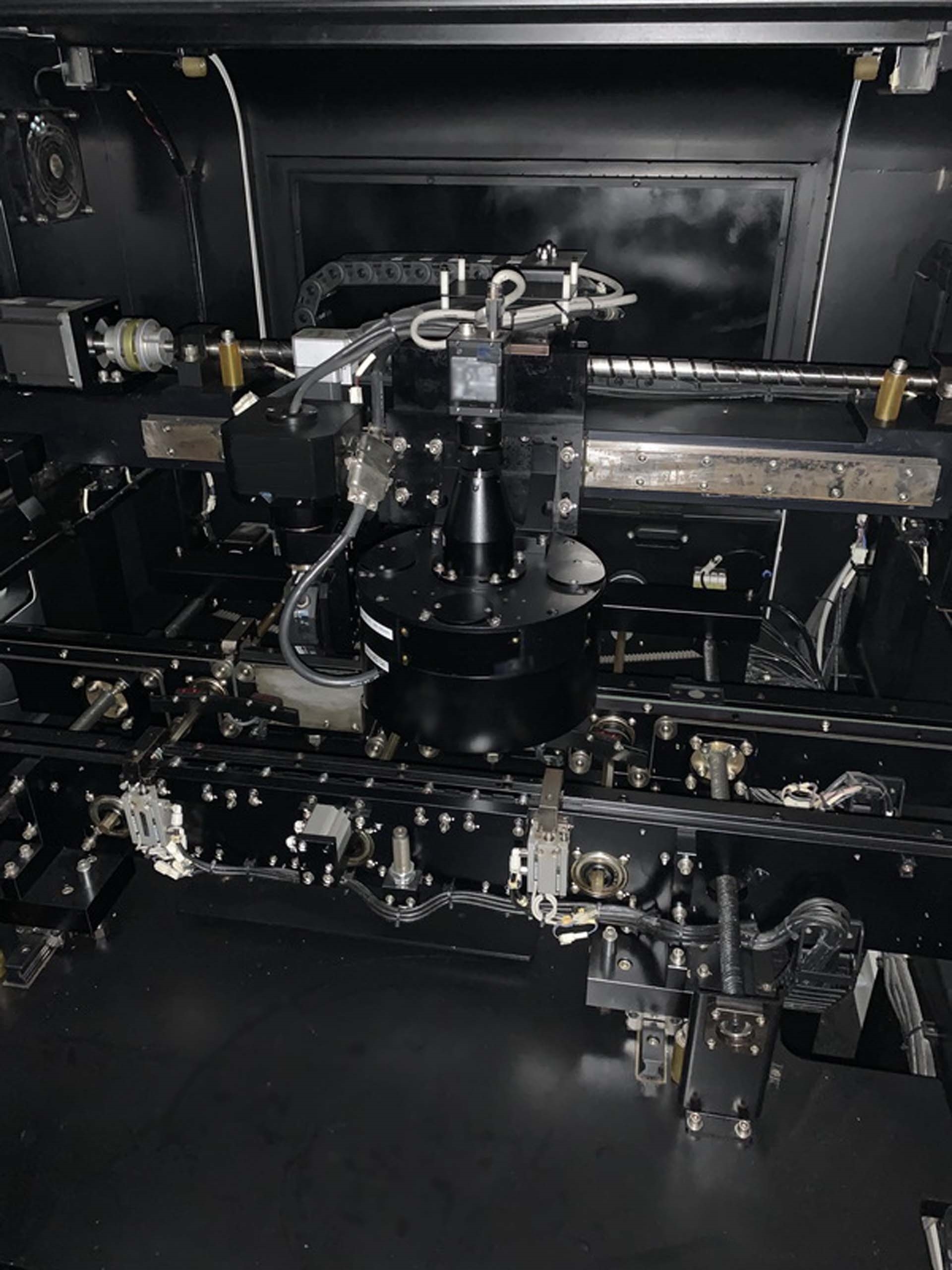

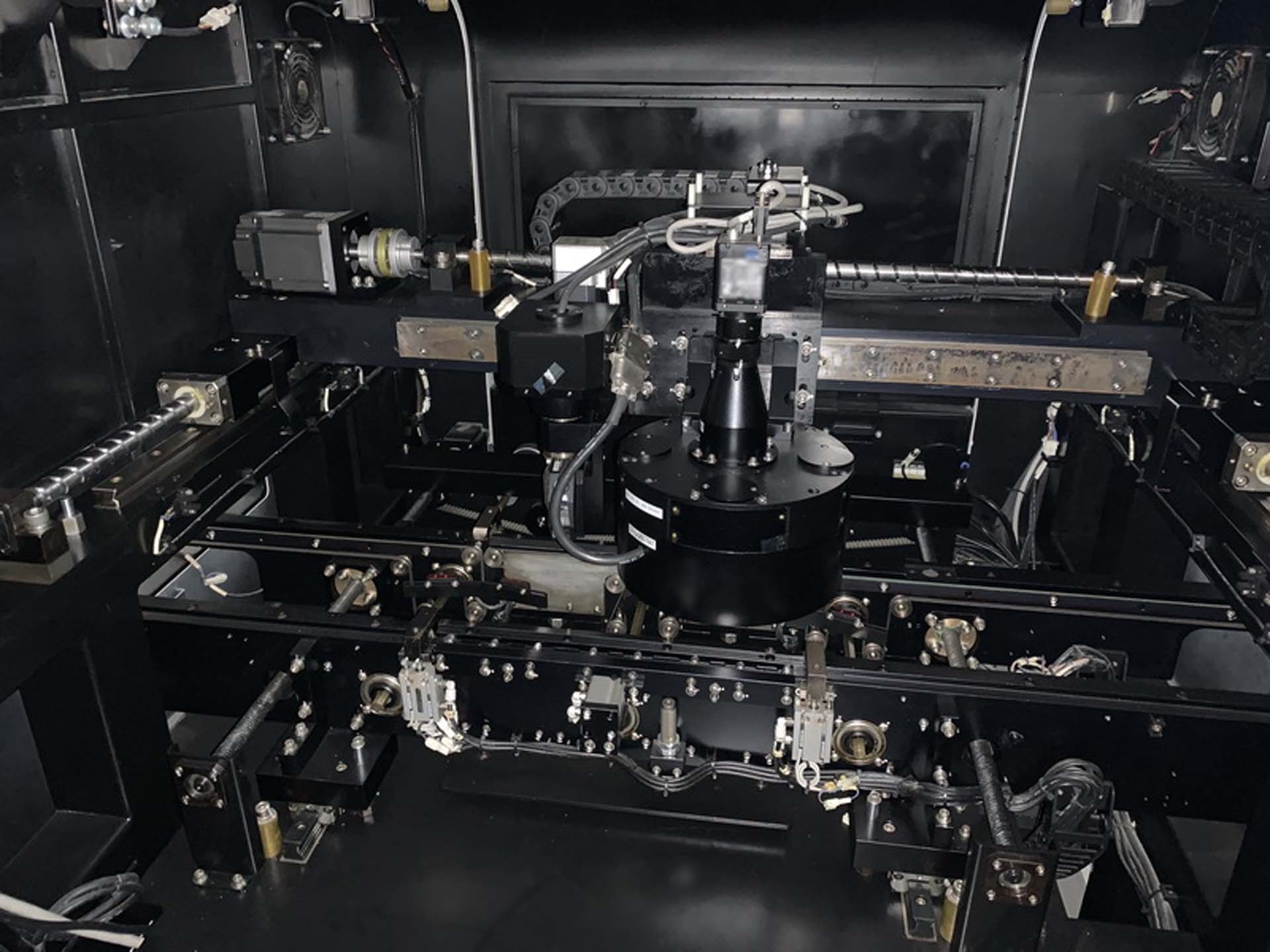

Used PHOENIX PA-500SB11 #9244958 for sale

URL successfully copied!

Tap to zoom

PHOENIX PA-500SB11 pc board assembly and manufacturing equipment is an all-in-one integrated solution designed for a wide range of customer requirements and situations. It enables the production of high-quality, finished printed circuit boards (PCBs) with surface-mount technology (SMT). The system is designed to handle standard leaded and lead-free processing, allowing up to 17,000 components per hour. It features a component prescription function that can automatically accommodate various components and sizes, as well as an integrated monitor unit for ensuring quality control. The platform is based on three main components: a component assembly robot, a high-frequency production line, and a component loading/unloading port. The component assembly robot is an industrial robot capable of precisely navigating PCBs and carrying out various assembly tasks, from component loading and placing to soldering. The high-frequency production line is an automated production line that is capable of soldering with laser-focused precision. Finally, the component loading/unloading port allows for precision component loading/unloading while also ensuring a clean working environment. PA-500SB11 features a wide range of advanced features, including full-integrated programmable logic controllers (PLCs). It is also equipped with a convenient operation panel and automatic overdrive testing, which provide users with an intuitive, user friendly experience. Furthermore, the machine has an integrated cooling tool for improved thermal management and ensures its environmental safety with an advanced dust-proof protection asset. Its quick assembly design and CAD data conversion capability allows users to quickly transfer and convert design data from their local network. In addition, PHOENIX PA-500SB11 includes line diagnostics capabilities that can be used for monitoring, troubleshooting, and accurate diagnostics. The model also offers an array of parameters that can be customized for production flexibility. Lastly, the equipment has an advanced industrial communication platform with protocol support that can communicate with automation systems and offer remote diagnosis and maintenance. Overall, PA-500SB11 pc board assembly and manufacturing system is highly efficient and reliable solution for a variety of situations. It is designed with a wide range of innovative features to enable the production of efficient and accurate Printed Circuit Boards (PCBs), making it optimal for high-quality PCB assembly and manufacturing.

There are no reviews yet