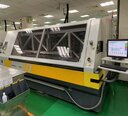

Used POSALUX Ultraspeed 6000 #9329011 for sale

URL successfully copied!

Tap to zoom

ID: 9329011

Vintage: 2002

PCB Drilling machine

Rotating speed: 180,000

2002 vintage.

POSALUX Ultraspeed 6000 is a high-performance pc board assembly and manufacturing equipment designed to increase process efficiency and throughput. It is equipped with a high-speed multi-functional pick-and-place station with an advanced vision system, allowing for fast and accurate positioning of components. Its powerful and highly-accurate 3-track multi-axis conveyor unit enables a precise and time-saving production process. For interface compatibility, Ultraspeed 6000 is equipped with real-time, open-frame industrial PC and motion control systems. All major data standards are supported, including Formula Direct (FDM), ODB++, Gerber, and IPC-A-600/620. The machine is capable of accommodating a wide variety of components, including SMT, TQFP, BVM, QFP, DIP, SOP, PLCC, LGA, FFC/FPC, and more. POSALUX Ultraspeed 6000 also provides advanced production support features to reduce time, cost, and labor. Automatic components feeder module supports up to 12 feeders for the entire production line with different material. In addition, this tool is equipped with an advanced soldering & bonding station that ensures reliable and accurate connection of components to the board. The various scheduling and optimization tools allow for efficient and optimized use of materials, labor, and resources. In terms of safety and reliability, Ultraspeed 6000 is equipped with a fault detection asset that can automatically halt the production line and correct any errors. All components are inspected and tested in accordance with the required IPC standards. The model can also automatically switch to standby mode in the event of a power failure, reducing the possibility of the production line being ruined. To sum up, POSALUX Ultraspeed 6000 is a pc board assembly and manufacturing equipment designed to increase process efficiency and throughput. It comes with features such as multi-functional pick-and-place station with an advanced vision system, 3-track multi-axis conveyor unit, automatic components feeder module, soldering & bonding station, scheduling & optimization tools, and fault detection machine. All of these features ensure efficient and reliable operation of the production line.

There are no reviews yet