Used PROTEC FDS-5000DM #293587129 for sale

URL successfully copied!

Tap to zoom

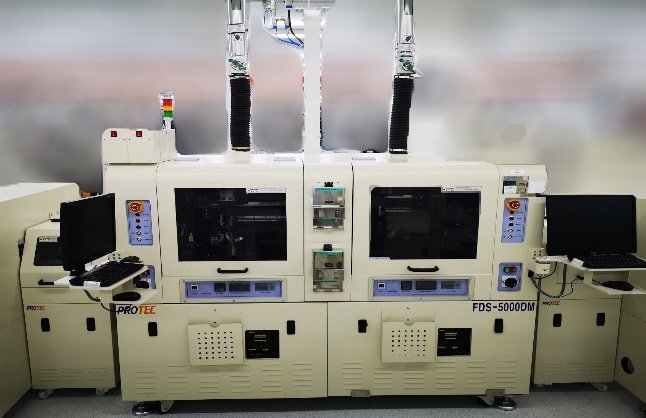

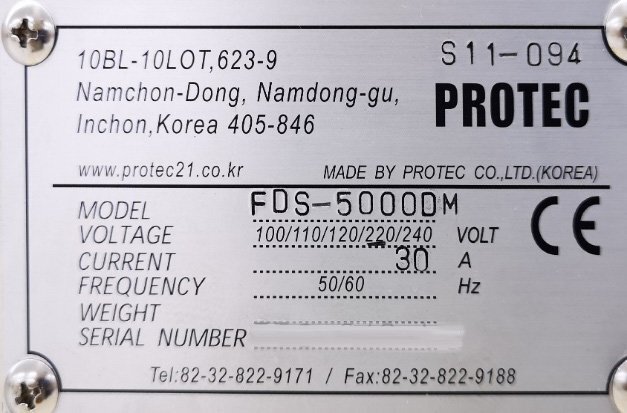

PROTEC FDS-5000DM is a PC board assembly and manufacturing equipment designed for PCBs (Printed Circuit Board) assembly and component mounting. It can integrate various component types, such as surface-mounted components (through-hole parts, SMT parts), as well as planar parts (resistors and other components). Through the built-in multiple axis controls, which include 5-axis scanning, it is possible to precisely place and mount the components with micron level accuracy. This system is equipped with intuitive software, allowing the user to enter commands, CAD data, and graphical instructions for PCB layout and component mounting. A variety of component-mounting methods, such as singlepoint and multiplepoint methods, are available, along with auto-positioning of components. This allows the user to quickly and accurately complete the assembly without sacrificing precision. FDS-5000DM technology also enables the use of a variety of signal lines, such as the connection of multiple boards, within the same PCB mount. This ensures reliable signal transmission and allows for more flexibility in the design of the PCB. The integrated multi-axis scanning makes for simple and quick adjustments in the positioning of the components. In addition, PROTEC FDS-5000DM features an advanced 3D vision unit, allowing it to identify components with a high degree of precision. This machine is also equipped with an anti-static feature, which eliminates static electricity build-up and prevents electrical shorts on the PCB. This feature helps to ensure the safety and quality of the final product. The user can also customize the tool to meet the particular needs of their product. FDS-5000DM asset can be programmed to contain specific commands and can be adapted to deal with components of various types and shapes. This further helps to ensure precision in the product assembly process. Overall, PROTEC FDS-5000DM is a powerful PC board assembly and manufacturing model that ensures precision in product assembly. Its intuitive design, integrated multi-axis scanning, 3D vision equipment, and comprehensive customization capabilities make it an ideal solution for efficient and accurate PCB assembly.

There are no reviews yet