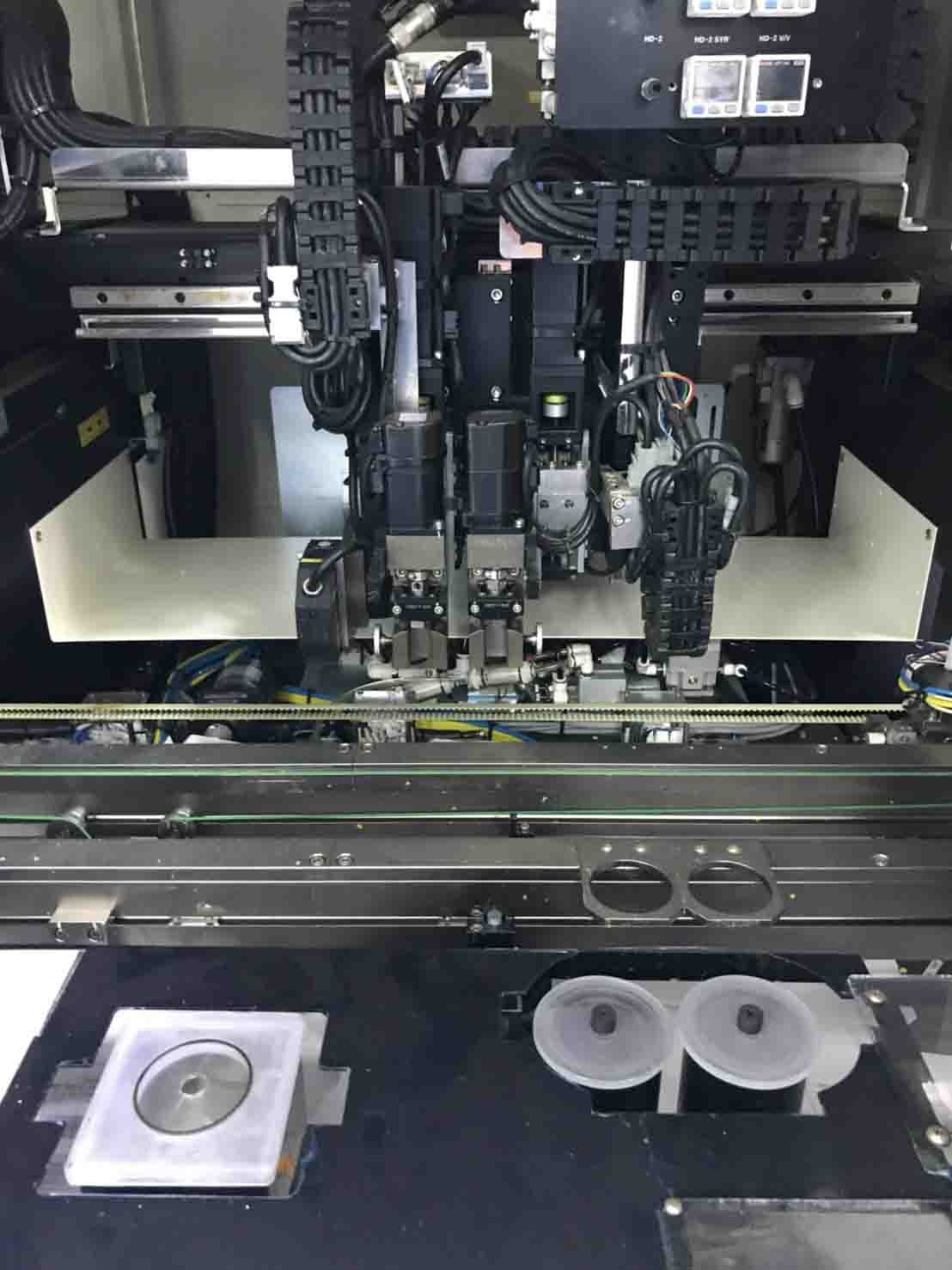

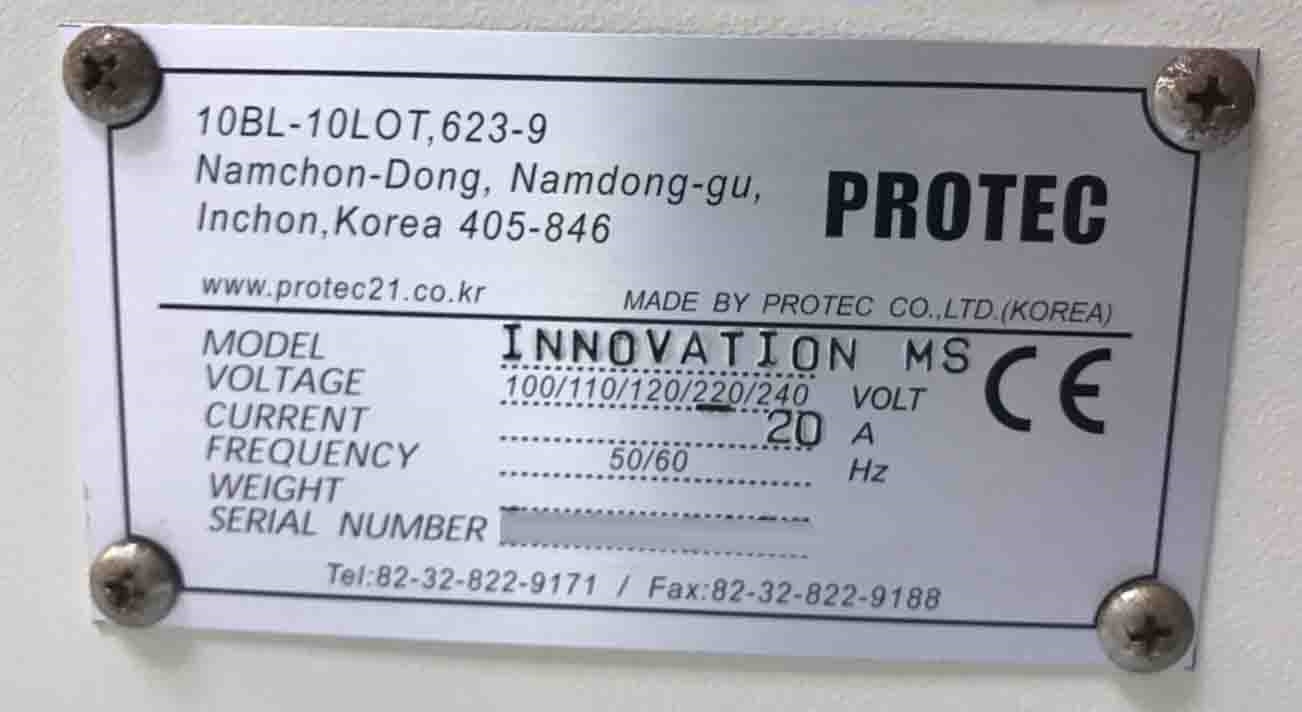

Used PROTEC INNOVATION MS #9199616 for sale

URL successfully copied!

Tap to zoom

PROTEC INNOVATION MS is an automated pc board assembly and manufacturing equipment. It is based on next-generation, Industry 4.0-oriented manufacturing system architecture. PROTEC INNOVATION-MS is equipped with innovative functionality for data processing and communication tasks (e.g. real-time communication between devices and distributed systems). The unit is designed to provide an effective and efficient workflow model for manual and automated pc board assembly. The machine is integrated with latest technologies such as robotics, computer vision, augmented reality, enterprise resource management (ERP), and machine learning/AI. The tool is engineered with a greater focus on traceability, quality, and real-time visualization. It is designed to provide high-quality assurance for pc boards and single components within a short cycle time. The asset adopts a modular design, which allows for the integration of alternative manufacturing processes and additional sensoring devices. Additionally, all relevant processes (e.g. 3D-printing, inspection, and test) can be incorporated in the model. INNOVATION MS is a robust manufacturing equipment for pc board assembly and manufacturing. It offers strong benefits over traditional processes, such as greater traceability, lower costs, improved quality and reduced manual labour requirements. The system is ideal for quick changeovers and volumes of high complexity and is suitable for medical, automotive, telecom and other advanced industries. INNOVATION-MS adopts a hybrid programming approach, combining manual and automated processes (injection moulding, lamination, schematics, etc.), as well as components supplied by automated storage and retrieval systems (AS/RS) and robotics. This allows flexible and precise setups of expected production cycles. The unit also provides automated data collection devices and statistical process control (SPC). Real-time trending of measurement results and sector reports deliver detailed performance data. Such structured data allows for more accurate and efficient production planning and material management. To ensure high quality of production, the machine uses state-of-the-art 3D-printing technology and automated critical component placements. The placement accuracy is enhanced by active feedback from the sensor tool. PROTEC INNOVATION MS aims to reduce overproduction, the production of defective products and incorrect products by providing a high level of quality assurance and automated processes. The asset is built for scalability, making it an ideal choice for small and large-scale organizations. It is capable of connecting to multiple relevant systems and supports open data exchange.

There are no reviews yet