Used PVA 2400 #9075347 for sale

URL successfully copied!

Tap to zoom

ID: 9075347

Conformal coating machines

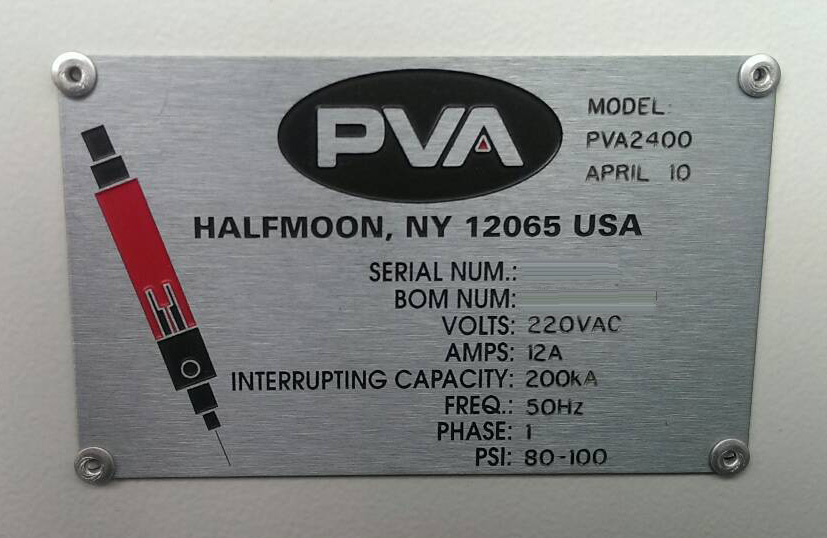

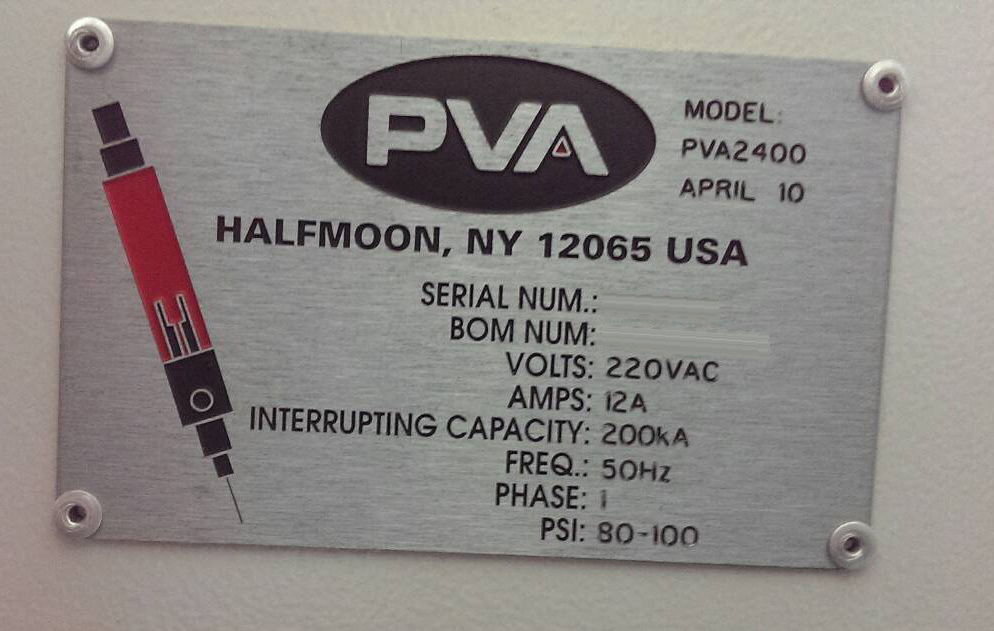

220 VAC, 12 A , 200 kA, 50 Hz, 1 Ph, 80 - 100 psi.

PVA 2400 is a unique PC board assembly and manufacturing equipment designed to allow users to quickly design, build, validate, and repair complex electronic assemblies. Utilizing advanced printed circuit board (PCB) assembly and manufacturing techniques, 2400 system allows for the production of intricate and complex PCBs and assemblies with a single touch of a button. PVA 2400 unit features an advanced Auto-Placer machine. This tool allows users to automatically place components onto PCBs with precise accuracy. This highly accurate asset is equipped with multiple camera monitoring, automated component sorting, and part placement to ensure quality control. The model also utilizes an advanced injection equipment that can rapidly place down and pick up components to quickly finish the assembly task. In addition, 2400 system includes advanced vision inspection capabilities to verify the accuracy and ensure quality of the assembly process. The vision unit utilizes advanced image processing algorithms to detect defects in components and misspellings to ensure that components and assemblies are of the highest quality. PVA 2400 machine is also equipped with a high-speed thermal transfer printer that utilizes advanced inks and screen printing technology to achieve high-resolution graphics. The temperature is also adjustable to ensure precision in the printing process. Finally, 2400 tool features the latest in surface mount technology (SMT) and automated soldering for constructing complex assemblies with ease. This asset is equipped with multiple robotic arms, driven by motor controllers, to quickly and accurately handle all soldering and SMT needs. This automated process allows for precision and accuracy while minimizing defects and rework. In all, PVA 2400 is an advanced model for PC board assembly and manufacturing that allows for the rapid and accurate production of complex and intricate PCBs and assemblies. This equipment is designed to help users reduce costs, improve quality, and reduce time-to-market.

There are no reviews yet