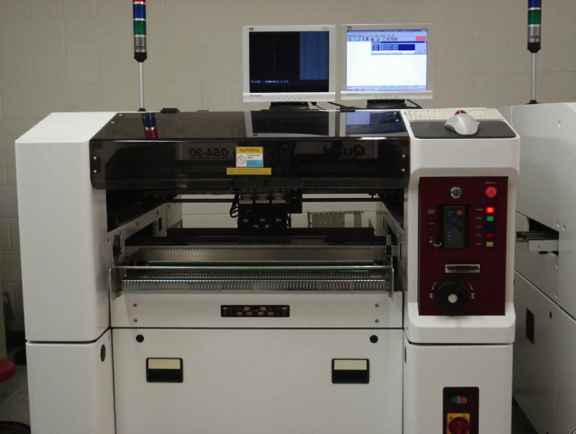

Used QUAD QSA-30 #133285 for sale

URL successfully copied!

Tap to zoom

ID: 133285

Vintage: 1998

Pick & place systems

13,000 CPH with assortment of feeders

Z-bellows and nozzles

1998 vintage.

QUAD QSA-30 is a PCB assembly and manufacturing equipment designed to streamline production. It has been designed to increase throughput, reduce scrap, and improve yields. This system is capable of placing components on single- or double-sided PCBs with sizes ranging from 0.031 inch (0.8mm) to 0.118 inch (3.0mm). It offers a wide array of components including surface mount, thru-hole, and odd-form parts with sizes ranging from 0201 to 30mm. The unit is driven by a highly efficient controller and Windows-based software developed by QUAD Automation. The user-friendly interface allows for simple part programming, production tracking, and data logging. A tooling station with a choice of tooling platforms and head configurations gives users the flexibility to accommodate a large variety of board shapes, sizes and geometries. In terms of placement accuracy, QSA-30 is capable of up to 0.025 mm on chip devices, with repeatability of 0.015mm. It is also equipped with a mispick-detection machine that can detect mispicks of up to 0603 components in real-time. QUAD QSA-30 also features an inline mass solder tool, which offers DPM (dispense-per-minute) up to 3000 dots for an array of high-speed board assemblies. The asset is equipped with a single or dual conveyor feeder model for accommodating multiple board sizes or ingredients. Additionally, it comes with a nozzle-cleaning equipment for efficient and reliable dispensing. Finally, the system includes 3D vision unit for automated inspection of assemblies. The vision machine is capable of detecting quality issues such as shorts, opens, incorrect polarity, bridges, tombstoning, missing components, bad coplanarity, and others. In conclusion, QSA-30 is a highly efficient, feature-rich PCB assembly and manufacturing tool designed to increase engineering productivity and reduce costs. It is capable of accurate and repeatable placements, along with inline solder and inspection capabilities, making it ideal for fast-paced production environments.

There are no reviews yet