Used QUAD QSP-2 #193124 for sale

URL successfully copied!

Tap to zoom

ID: 193124

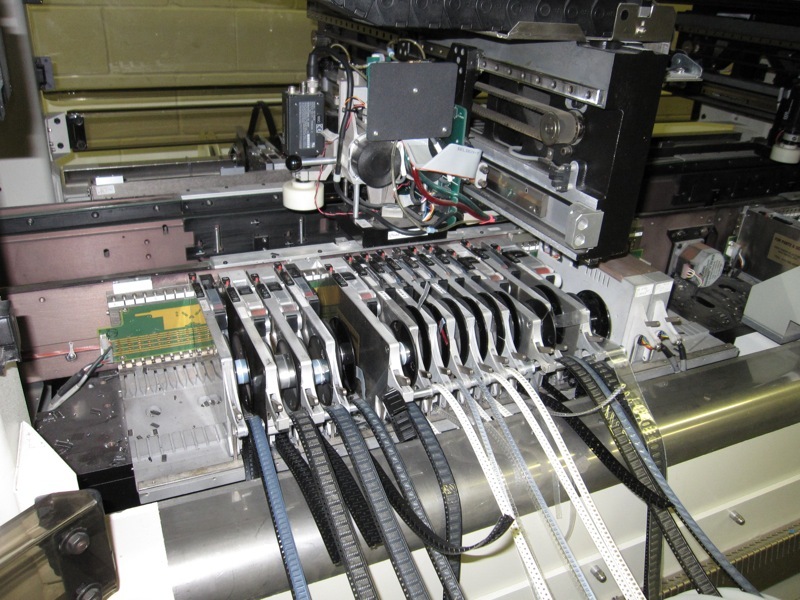

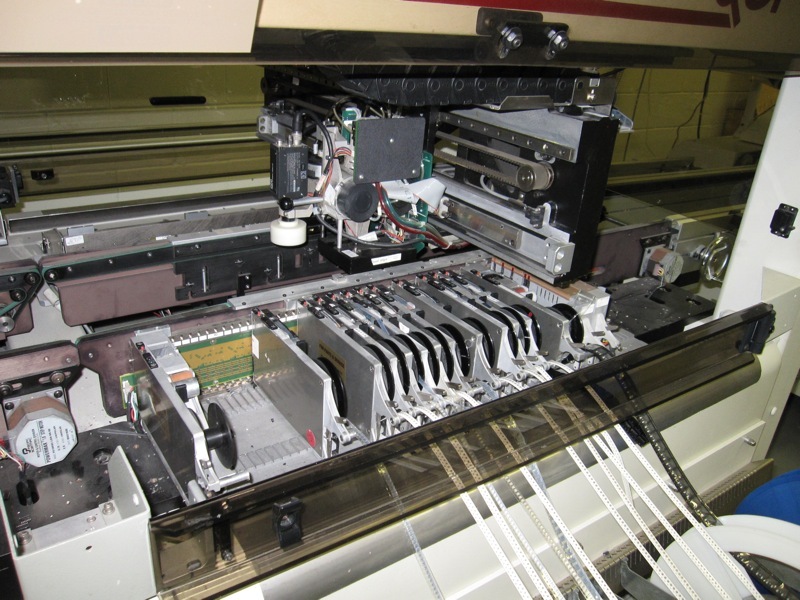

Pick and place machine

Feeders:

(34) 8mm

(6) 12mm

(3) 16mm

(9) nozzle changer

(2) vib base.

QUAD QSP-2 is an advanced PC board assembly and manufacturing equipment designed to meet the highest levels of quality control and production speed. It is specifically engineered to help manufacturers increase productivity by reducing scrap rates and increasing production throughput. This system is capable of high volume production with an excellent performance level. The core of QSP-2 is its innovative software platform, which provides comprehensive automation of the entire board assembly and manufacturing process. The unit supports both pick and place and manual assembly, with a variety of components including TH, SMT, and BGA (ball grid array) components. The machine also provides an integrated database for components and materials. Using the software platform, users can easily plan and monitor production processes, optimize the factory flow, and reduce both labor and materials costs. QUAD QSP-2 is also designed for efficient repair and rework processes. It offers customizable resolution options, including the ability to select individual test points and track component analysis. Furthermore, it is equipped with high-precision sensors that accurately detect defects and individual lesions in PCBs. This allows for fast and accurate rework. QSP-2 also offers a robust manufacturing management tool, which enables detailed analysis of real-time production data including throughput times, defect rates, inventory, and cost management. Additionally, it offers a comprehensive traceability asset, allowing manufacturers to easily track the origin and destination of all parts and components used in the production process. Finally, QUAD QSP-2 is designed with safety in mind, providing numerous safety features including static sensitive protection, air part safety activation, and environmental extremes protection. Overall, QSP-2 is an advanced PC board assembly and manufacturing model designed to meet the highest quality control and production speed standards. Its innovative software platform provides comprehensive automation of production processes and efficient repair and rework capabilities. In addition, the equipment offers a robust manufacturing management system and comprehensive traceability unit. Lastly, safety features ensure safety in the production process.

There are no reviews yet