Used QUAD QSP-2 #9124796 for sale

URL successfully copied!

Tap to zoom

ID: 9124796

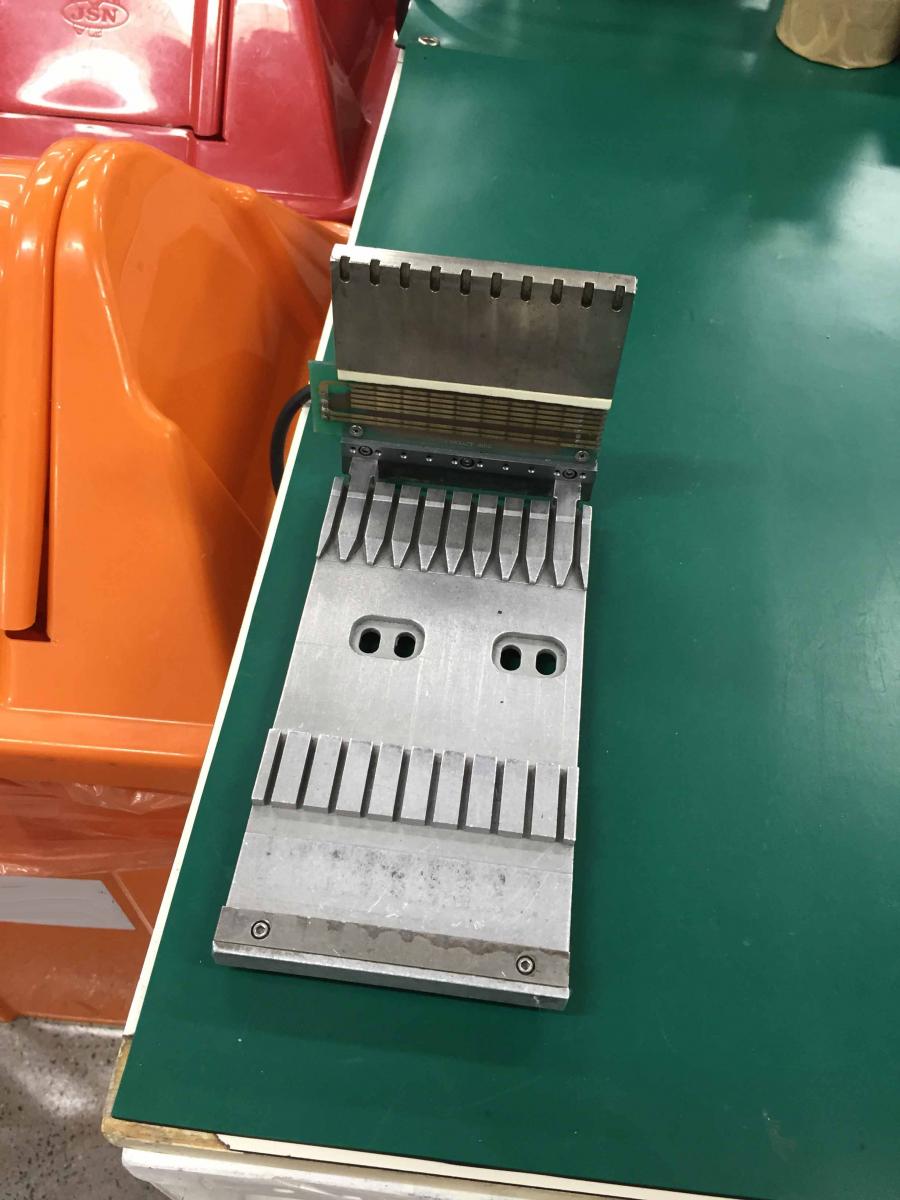

Pick and place machine

Right to left

Left to right

Automatic conveyor adjust

(4) P4 Heads

Voltage: 200-240 VAC

50 / 60 Hz.

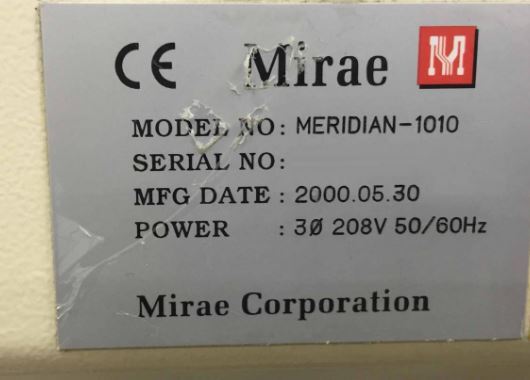

QUAD QSP 2 is a pc board assembly and manufacturing equipment designed and manufactured by QuadTech. The system is prepared for surface mount and various thru-hole components, and offers a wide range of automated assembly and control capabilities. The unit is built around the base unit, which is composed of an industrial grade PC loaded with the latest Windows operating machine and an on-board automation controller. The base unit is connected to the main assembly process components including automated pick and place machines, stencil printers, inspection systems, reflow ovens, and board handling equipment. In addition to being connected to these components, the base unit contains a complete data acquisition tool and integrated control asset that enables the model to perform functions such as data logging, recipe management, process control, and machine diagnostics. The equipment is designed to deliver high-volume production of pc boards for assembly and manufacturing needs. With the integrated data acquisition and process control, the system can monitor and adjust assembly parameters in real time, ensuring consistent product quality. The pick and place machines can be configured to work with a variety of components, including chip resistors, capacitors, and integrated circuits. Additionally, the setup and change-over of the assembly process is automated and can be directed from the unit control point. QSP 2 is also capable of performing post assembly operations such as inspection and assembly verification. This is accomplished with a combination of an integrated vision machine and several auxiliary control points, helping to ensure product quality is maintained. The custom design feature allows the user to tailor the tool specifications to their specific application, ensuring optimum performance in the process. The main advantage of QUAD QSP 2 asset is that it enables the user to achieve high-volume production of pc boards in a cost effective, accurate, and consistent manner. The combination of automated processes, integrated control, and data collection give this model the ability to produce pc boards with decreased costs and increased quality. The equipment is also designed to be user-friendly and intuitive, allowing for easy set up and control of the assembly process.

There are no reviews yet