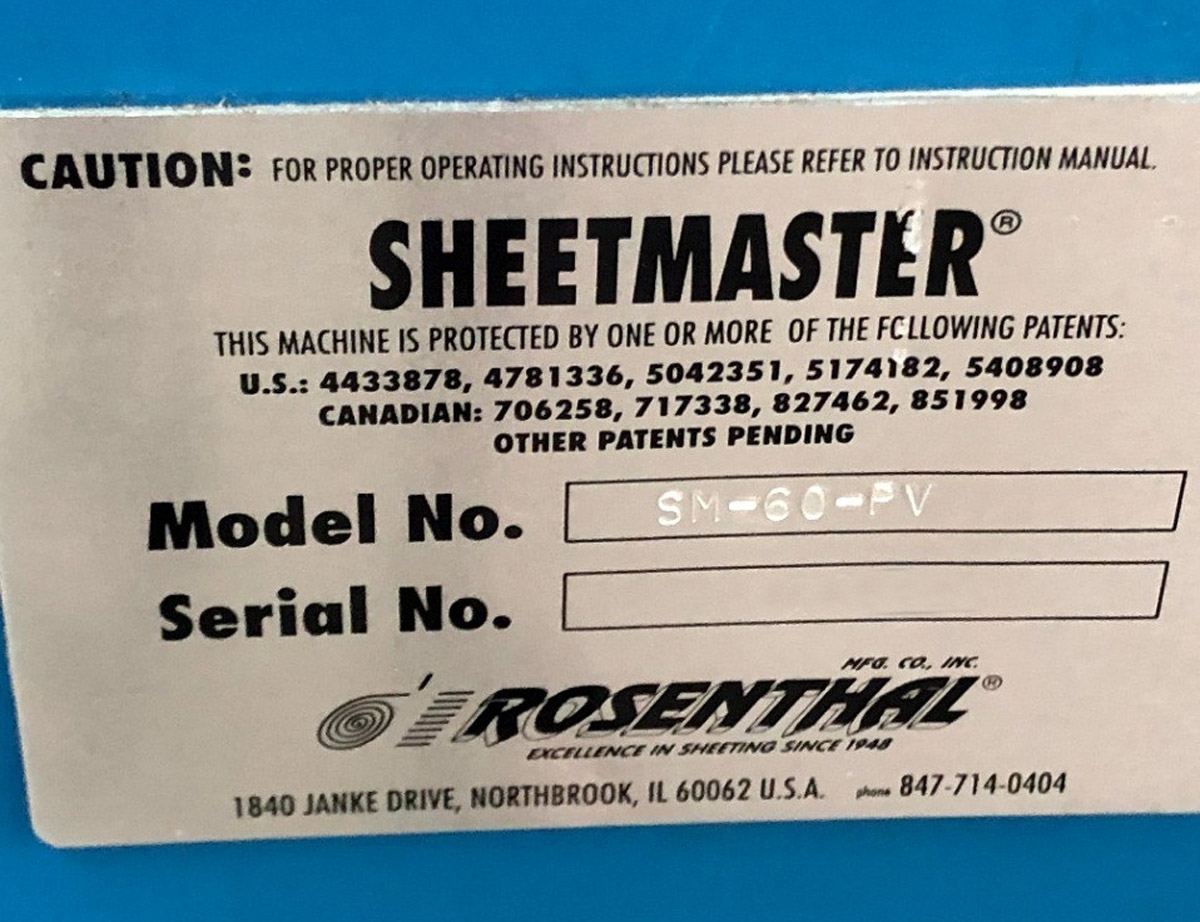

Used ROSENTHAL Sheetmaster #9268036 for sale

URL successfully copied!

Tap to zoom

ROSENTHAL Sheetmaster is a PC-based equipment for assembly and manufacturing of printed circuit boards. It is designed to increase efficiency and accuracy in PC board manufacturing by providing a powerful automation platform through which PC board designs can be quickly and precisely assembled. It offers a multitude of features, such as high-speed routing, advanced placement, panelization, and reflow techniques, as well as intelligent loading and unloading functionality. Additionally, the system provides efficient, reliable, and accurate placement of components on the boards using its advanced placement techniques. Sheetmaster unit consists of a PC board design application, a high-speed router and placement head, integrated vision systems, laser imaging technology, and precision manufacturing tools. The PC board design application allows for easy customization of the PC board design to meet customer specifications. It also includes tools for the generation of Gerber files, which simplify the fabrication process and increase production speeds. The high-speed router and placement head make the components placement process quicker and more accurate. The integrated vision machine works in tandem with the router to accurately identify and place components. It ensures the correct assembly and placement of each component when placed on the board. The laser imaging technology of ROSENTHAL Sheetmaster enables the application of multiple layers of solder mask in a single pass, resulting in increased manufacturing speed and accuracy. Similarly, the precision manufacturing tools of the tool provide precise measurements, ensuring that components are placed accurately on the board. Lastly, with its intelligent loading and unloading techniques, the asset is able to place specific components in designated areas on the boards during loading and unloading to meet customer demands. Overall, Sheetmaster model provides automated and robust manufacturing solutions. With its wide range of features, it enables customers to quickly and accurately manufacture their printed circuit boards, resulting in faster turnaround times and fewer errors. It is a reliable tool that can be used to ensure that PC boards are consistently made with high quality.

There are no reviews yet