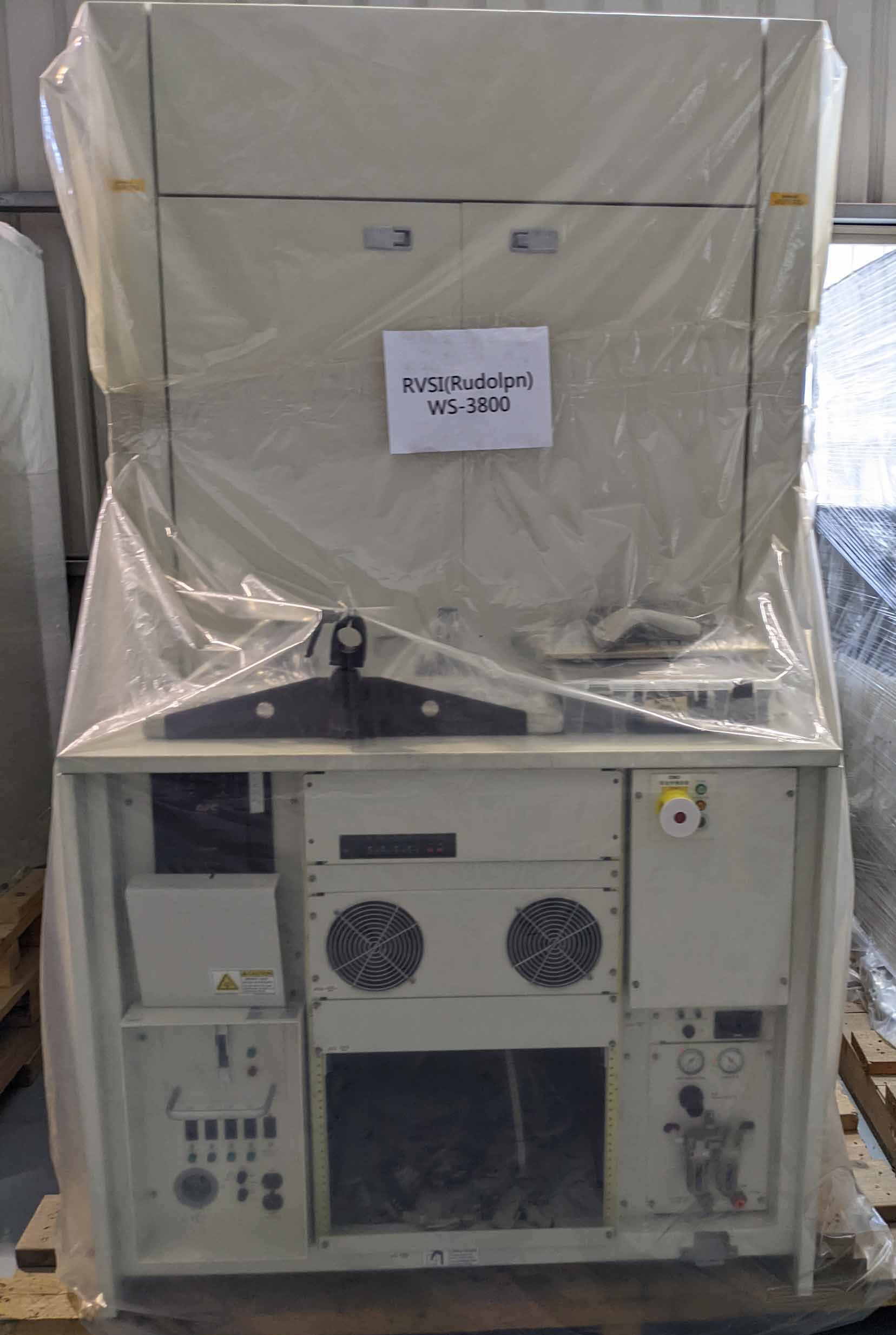

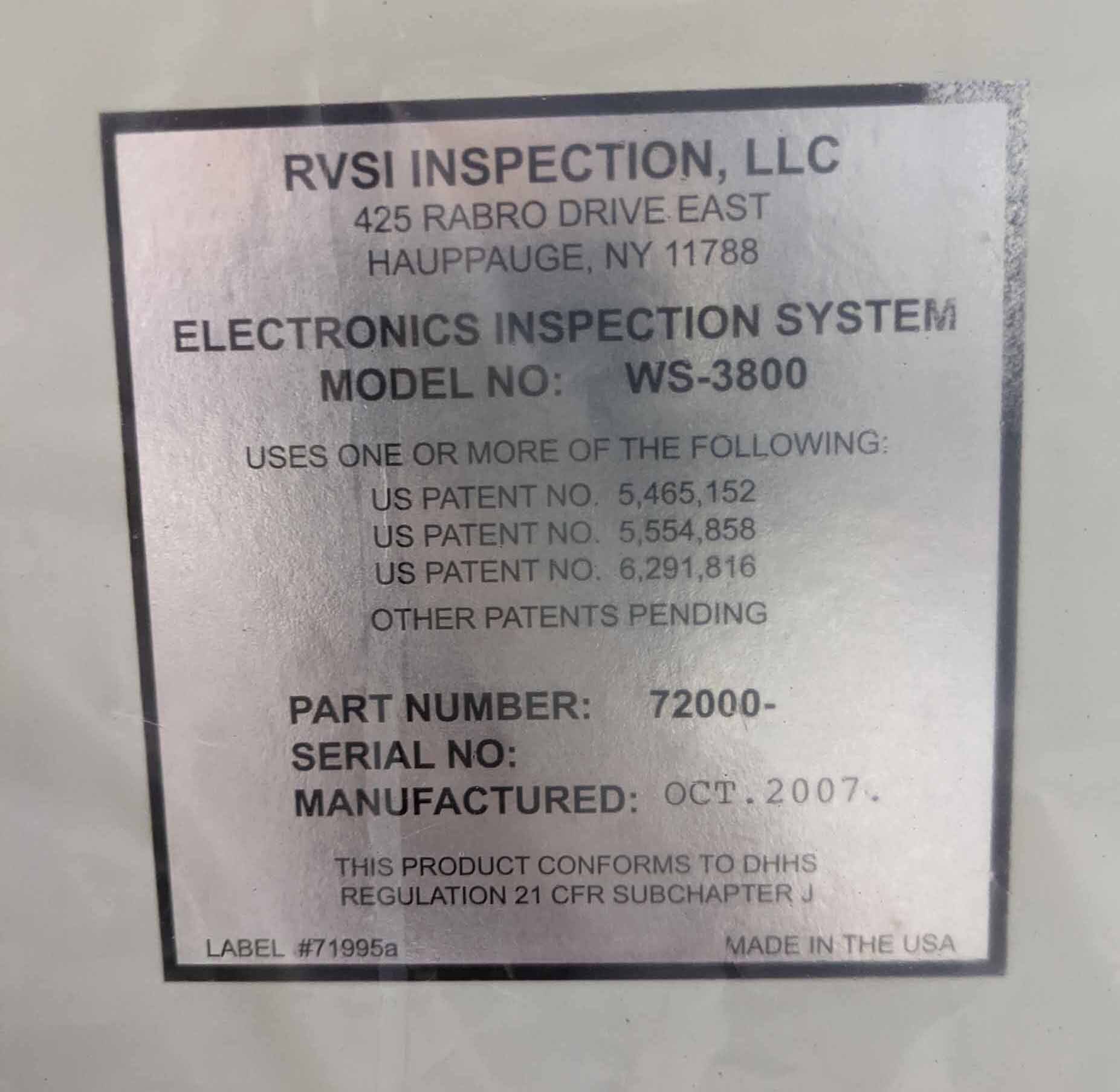

Used RVSI / VANGUARD / RUDOLPH WS 3800 #9308833 for sale

URL successfully copied!

Tap to zoom

ID: 9308833

Wafer Size: 8"

Vintage: 2007

2D / 3D Automated Optical Inspection (AOI) system, 8"

2007 vintage.

RVSI / VANGUARD / RUDOLPH WS 3800 equipment is a PC board assembly and manufacturing system designed to simplify the production process for a wide variety of electronic products. The unit integrates high-speed pick-and-place equipment with advanced automated optical inspection capabilities to ensure the highest quality standards are achieved. The machine is also equipped with a range of integrated robotics, advanced motion control software, and parts placement programming to maximize production speed and efficiency. This ensures that the production of complex, custom PC board configurations becomes a streamlined, automated process. The tool handles most flexible parts, components, and modules on the market and offers self-motivating and self-adjusting clamping technology for secure and accurate pick-and-place operations. The asset is also capable of performing a range of other functions such as pin-in-hole insertion, component testing, and more. This is thanks to the use of sophisticated sensors and actuators, which can adjust and optimize the performance of the model as needed. The equipment is also capable of flexible routing for the optimization of automated assembly processes. RVSI WS 3800 system is also equipped with integrated self-diagnostics, which allow for the fast and precise detection of unit errors. It can also detect and adjust for a range of potential production errors. Another highlight is the machine's extensive library of programming data, which can be used to help create complex electronics designs that are highly accurate and consistently reliable. RUDOLPH WS 3800 tool also features convenient remote access capabilities, allowing users to control production from anywhere using an Internet connection. The asset is also compatible with many industry-standard software programs and provides an extensive array of features and options, which can be customized to fit specific production needs. In conclusion, WS 3800 model offers an unbeatable array of features and options to simplify and streamline the production of complex electronic products. Its flexible and intuitive software tools, powerful sensors and actuators, and advanced robotics ensure highly precise and consistent production results, while its remote access capabilities and self-diagnostics capabilities further upgrade its production efficiency.

There are no reviews yet