Used S&M PTB-510 #9358352 for sale

URL successfully copied!

Tap to zoom

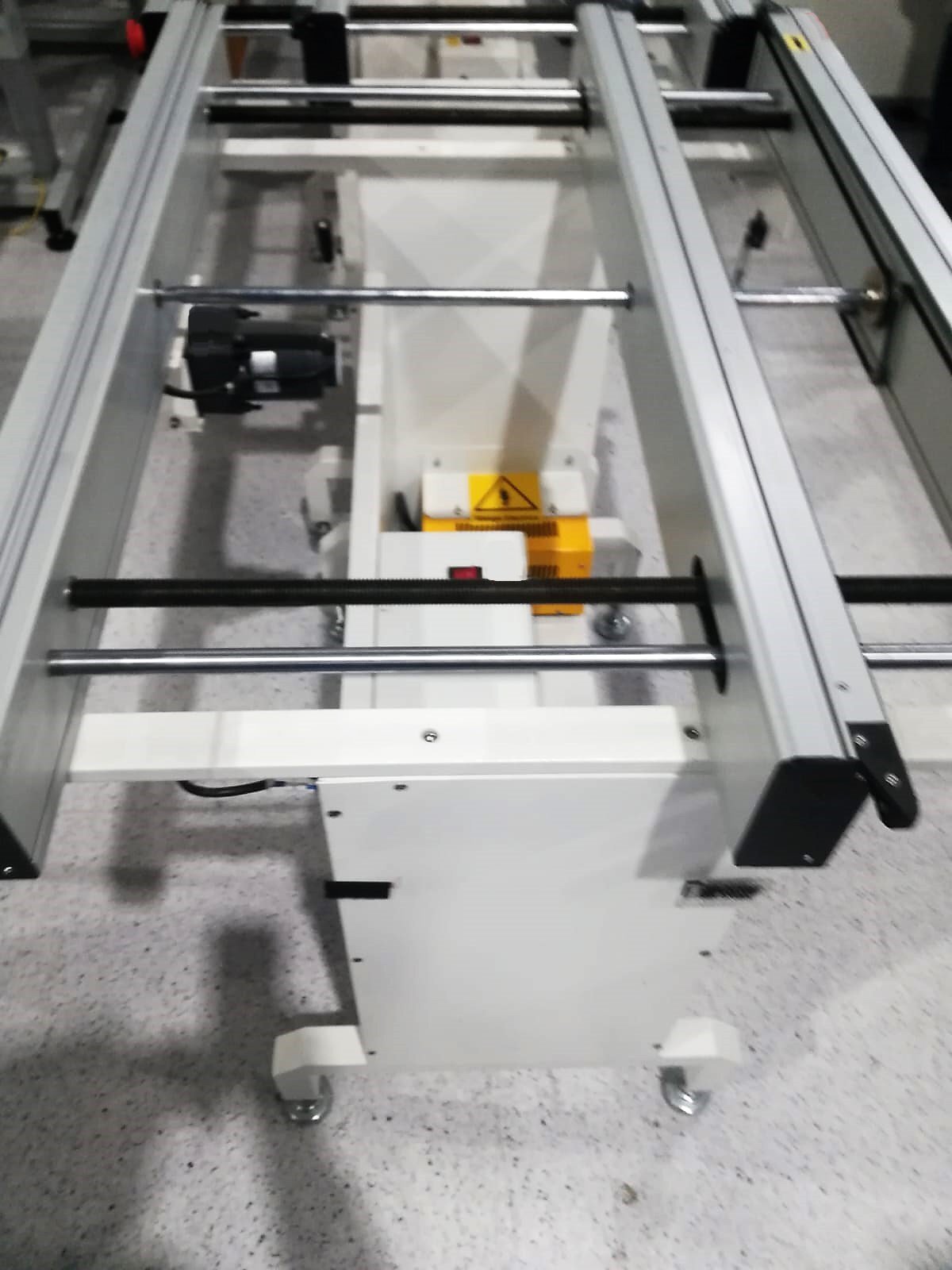

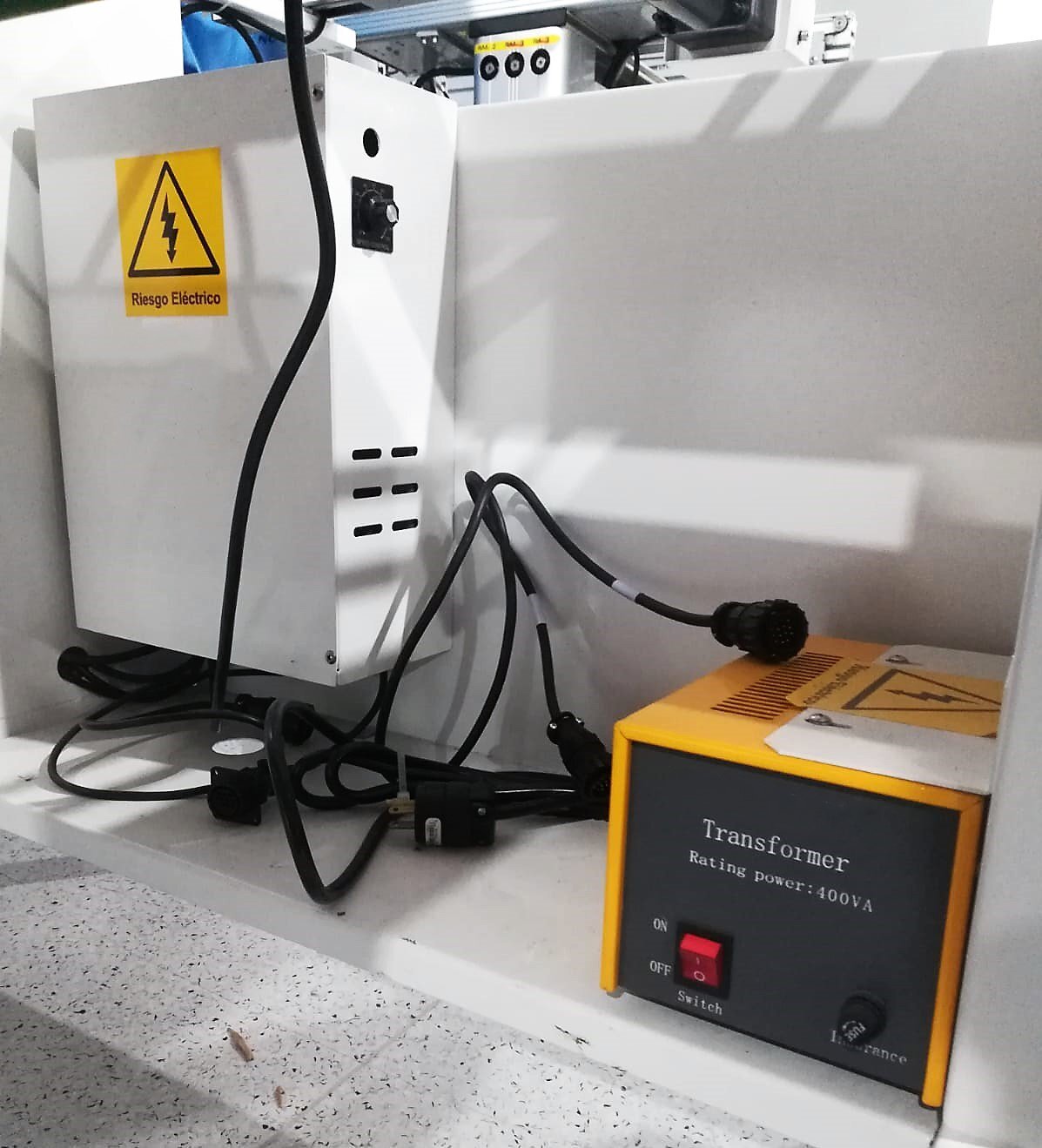

S&M PTB-510 is a powerful pc board assembly and manufacturing equipment designed for rapid component placement and soldering processes. This efficient system is made up of an automatic feeder, camera component recognition unit, component pick-up head, solder paste dispensing nozzle, and an on-board reflow oven. The entire unit is powered by a PLC (programmable logic controller) and benefits from the latest machine vision technology for fast and accurate placement of all components onto the pc board. The automatic feeder utilizes a storage rack machine that holds a wide variety of components. These components are then propelled onto the placement area by a hopper-driven wheel. A photo recognition camera then scans each component as it is placed, and the pick-up head unit is modified to accommodate the component size, shape, and type. The solder paste dispensing nozzle then precisely dispenses solder paste onto the applicable placement sites. PTB-510 is designed to be incredibly fast and accurate, priding itself on its high-speed capability. It is capable of reaching speeds of up to 50 component placement sites per second, with a pitch accuracy of just 0.02mm and placement accuracy of 0.1mm. The tool also includes a variety of sensors for post-placement placement tests in lieu of actual testing processes. Also, the PLC ensures that consistent levels of accuracy and precision are maintained throughout the entire process. Thanks to its efficient use of energy, S&M PTB-510 also offers impressive energy savings and a low carbon footprint. Hot air of up to 230 degrees Celsius is used to reflow soldering, which helps to reduce energy wastage. The asset is also designed to be incredibly reliable, with repeatability tolerance of just 0.02 mm. This ensures that the production process is highly efficient, minimizing waste and errors. Overall, PTB-510 is an advanced and reliable pc board assembly and manufacturing model. Its combination of high speed and advanced scanning and placement capabilities makes it a powerful tool for maximizing efficiency in the production process. Its energy-saving and low temperature operation also ensures its sustainability, ensuring minimal costs and waste over the long-term.

There are no reviews yet