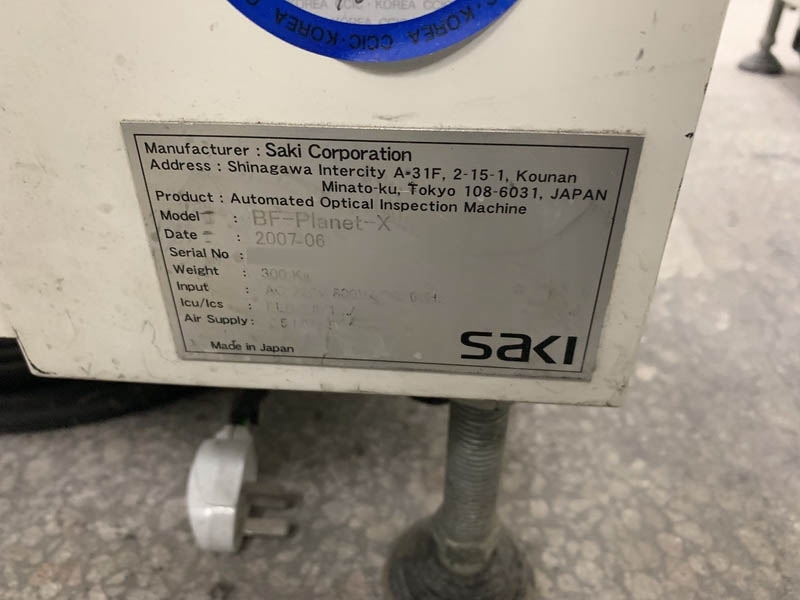

Used SAKI BF-Planet-X #9254870 for sale

URL successfully copied!

Tap to zoom

SAKI BF-Planet-X is a complete PC board assembly and manufacturing equipment that automates the entire production process from component placement to board population. It provides a reliable and cost-effective solution with automated feeding and alignment for a variety of components, ranging from 0402 resistors to larger components such as BGA packages. The system provides advanced motion control and sophisticated image processing with a CCD camera to ensure accurate and error-free placement of parts. The feeders can accommodate different types of components including surface-mount and through-hole technology. The feeder is equipped with a high-speed brushless motor for precise and consistent parts placement. BF-Planet-X operates using a camera-based optical chip recognition unit that automates the hardware-level assembly and manufacturing process. This technology is used to quickly scan and identify components including barcodes and logos as they pass through. This helps improve accuracy and efficiency while reducing human errors. The machine also offers an automated board stuffing function with a high speed pick-and-place head. This option can be used to populate boards quickly and accurately. The tool can also be equipped with a laser cutting and drilling machine to precisely cut and drill PCB edges to ensure a precise fit for components. SAKI BF-Planet-X is fully compatible with software applications for programming, analysis, monitoring and diagnostics. This allows the user to control all aspects of the production process from a single interface. The asset can be used for both production lines and prototyping and can be easily integrated into existing production processes. BF-Planet-X is a reliable and cost-effective solution to reduce labor costs and increase production efficiency. It is an ideal model for PCB manufacturing and assembly and provides an extensive range of features and benefits.

There are no reviews yet