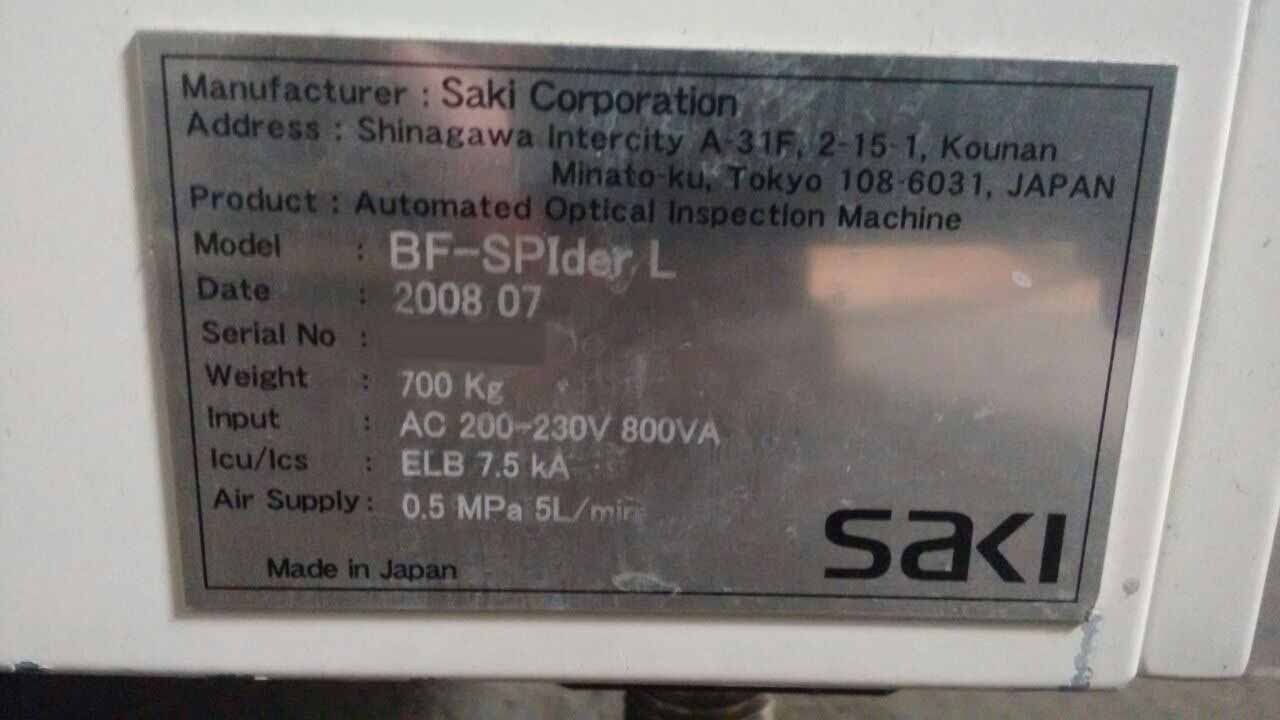

Used SAKI BF-SPIder L #9176873 for sale

URL successfully copied!

Tap to zoom

SAKI BF-SPIder L is a "Pick-and-Place" machine used in printed circuit board assembly and manufacturing. It features an advanced vision-aided equipment that significantly improves accuracy and speed compared to manual labor. The system features a conveyor belt that carries the circuit boards and components and transfers them to an X-Y stage, which then distributes them to individual machines, allowing production processes to be completed quickly and efficiently. BF-SPIder L is capable of preparing, sizing, cutting, sorting, program and organizing parts and assemblies. SAKI BF-SPIder L also boasts an integrated X-ray unit that can detect and inspect features on both the top and bottom sides of a printed circuit board assembly. It can identify a range of features, including solder joints, component alignment, component warping, and tracking of components of all sizes. The machine can also identify defects, minimize false positives, and fabricate a report to help diagnose the features. BF-SPIder L also features a universal camera structure with a wide field of view at high resolution. This ensures that components are accurately aligned and all solder joints are correctly placed. Furthermore, it has a modern GUI/MSO interface that enables users to work with a variety of settings and programs. SAKI BF-SPIder L is configured with a comprehensive production process that includes an automated conveying tool, conveyor belt, feeders, part holding chuck, chip shooters, boards, stencils, and PCB loader. BF-SPIder L also has multiple tools for dispensing, collecting, measuring, and managing data. Automated tool calibration reduces setup time and supports multiple materials. Furthermore, the user-friendly data handing asset eliminates manual input and provides real-time feedback. The data may also be exported to software such as Proficy CIMConnect for data analysis. SAKI BF-SPIder L's Semi-Automatic Program Editor (SAPE) provides a highly configurable control routine for data deployment, allowing users to tailor the model to their particular manufacturing requirements. The equipment includes a powerful Nozzle Changeover system that allows for rapid nozzle changing and temporary nozzle storage during product changeovers. The data-driven Nozzle Layout Feature (NLF) provides the user with a quick and easy way to develop nozzle mappings to achieve optimal component placement. In conclusion, BF-SPIder L is a powerful, integrated board manufacturing and assembly unit that uses advanced vision-assisted technology to perform tasks quickly and accurately. It features an integrated X-ray machine for quality inspection, a universal camera structure, a modern user interface, a semi-automatic program editor, and a nozzle changeover tool for rapid component placement. The asset also has multiple tools for handling and data management, allowing users to tailor the model to their particular manufacturing needs.

There are no reviews yet