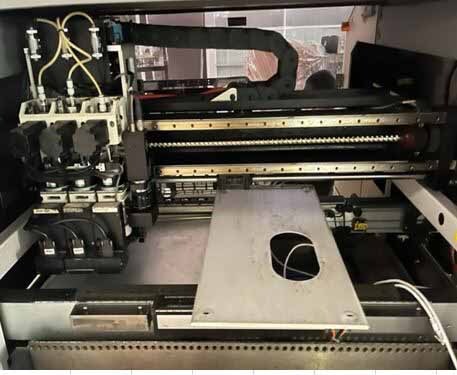

Used SAMSUNG CP-40L #293641435 for sale

URL successfully copied!

Tap to zoom

SAMSUNG CP-40L is a powerful PC board assembly and manufacturing equipment used to rapidly produce high-quality, high-density Printed Circuit Boards (PCBs). It features an innovative design that allows boards to be produced quickly and efficiently with minimal setup time. The system is composed of a frame structure designed to house the main components of the unit and the associated I/O components. The frame structure holds the PCB manufacturing systems which include the main controller, the panel alignment assembly, the board transfer conveyor, the coating line, the plating line and the conveyor bridge. In addition, it also includes software that allows for the control of the production process as well as the reporting of results. The main controller is responsible for controlling the entire process from start to finish. It offers precision control and accuracy in order to produce quality products with minimal setup time and a consistent process for each product. It is equipped with a LCD monitor equipped with touch screen technology which allows for the smooth and efficient operation of the machine. The panel alignment assembly is responsible for aligning the panels in order to ensure that they are in the proper place in relation to other panels. The board transfer conveyor is responsible for the movement of the panels from one area to another. The coating line is used in order to provide a protective coating to the boards before they proceed through the manufacturing process. This helps to ensure that the boards remain in optimal condition throughout the entire production process and to make sure that they remain free of any dust or debris. The plating line is responsible for the plating of the boards and this step is used to provide the necessary electrical connections for the components on the board. The conveyor bridge is responsible for the actual assembly of the board and this is done using an automated assembly logic that allows for the efficient and accurate assembly of the components onto the board. The machine is also equipped with diagnostics software that can detect any abnormality found during the assembly process and provide corrective instructions in order to rectify the issue in a efficient and timely manner. CP-40L is a robust and reliable tool that is designed to provide a reliable and efficient production line for PC board assembly and manufacturing. It is suitable for a variety of different applications and provides increased productivity and accuracy in order to produce top-quality products.

There are no reviews yet