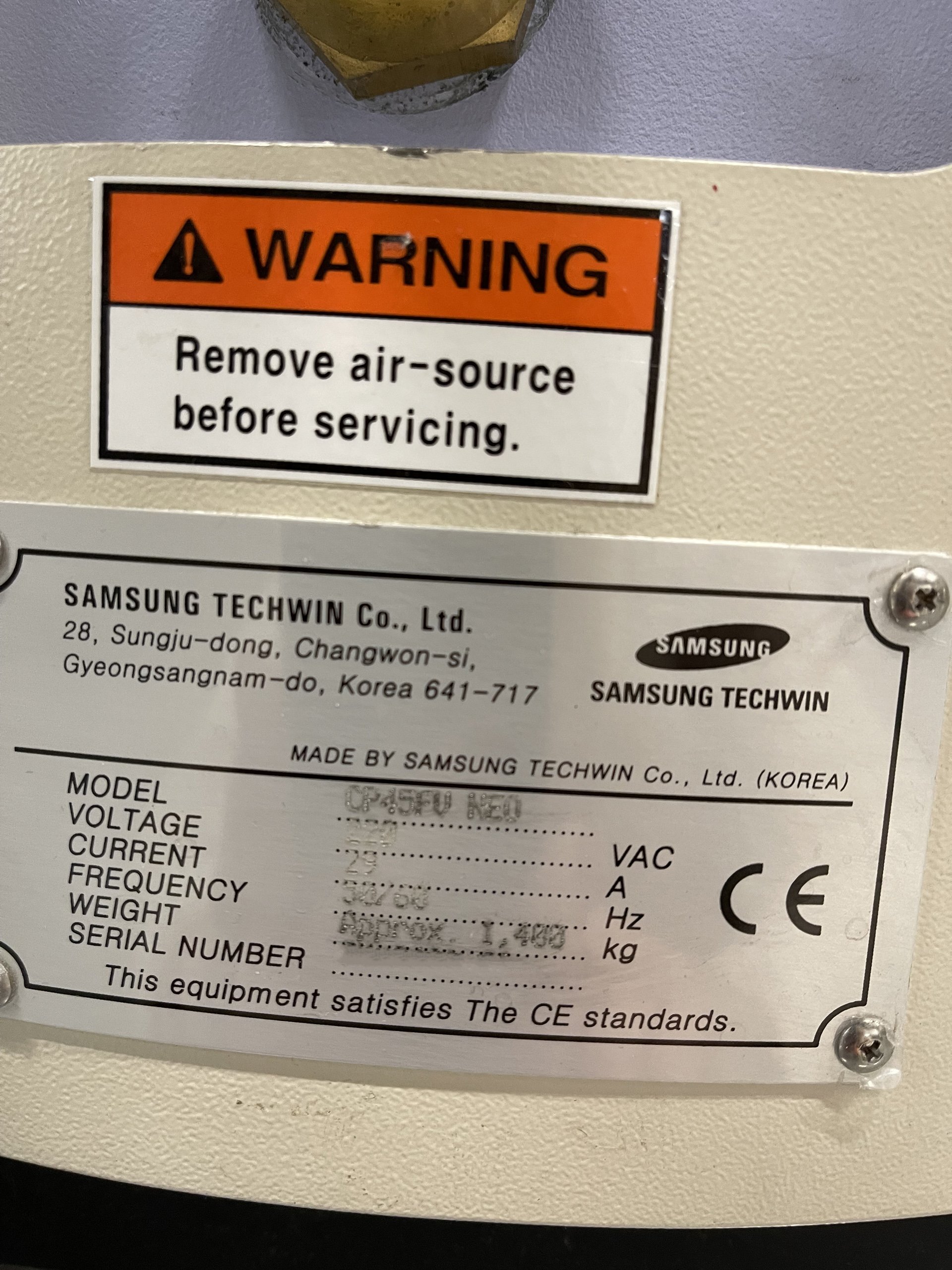

Used SAMSUNG CP-45FV NEO #293656613 for sale

URL successfully copied!

Tap to zoom

ID: 293656613

Vintage: 2010

Pick and place machine

Process flow: Left to right

Nozzles

Gantry

(6) Spindle heads

(104) Fixed feeder bases

Flying and fixed vision

Modified panel, 23" x 16" from standard 18" x 16"

Component range: 0201 to 22mm²

Operating system: Windows XP

Running hours: 43,608

Power supply: 220V, 29A, Single phase

2010 vintage.

SAMSUNG CP-45FV NEO is a high-performance PC board assembly and manufacturing equipment designed for high-volume production. This complete all-in-one solution offers a streamlined design for maximum efficiency, and superior accuracy and reliability. SAMSUNG CP45FV NEO is designed to automate the loading and unloading process so that operators can complete manual tasks faster and more accurately. The machine features an intuitive user interface with built-in screen and voice guidance which allows quick setup and operation. It can also be customized to meet specific requirements, and is compatible with various communication protocols such as PCIF, PCMIF and etcetera. CP-45FV NEO features three independent spindles plus a special deep hole drilling spindle. The spindles can be freely rotated or servo-controlled to accommodate various types of materials and components. The different spindle types include drilling, cutting, grooving, tapping and threading. The innovative drill synchronization system ensures an optimal machining process. In addition, CP45FV NEO has an integrated feeder unit and a built-in component sorting routine for the production of high-precision parts. The machine offers high-speed feeder positioning, highly accurate compensation algorithms, and low cost of ownership. SAMSUNG CP-45FV NEO is equipped with advanced safety features, including a touch-sensing gloves protection machine and a 3D scanning laser protection tool. This ensures that operators can work safely in the vicinity of the machine, and the safety design also complies with the requirements set out in the European Machinery Directive. For quality control, SAMSUNG CP45FV NEO is equipped with an online defect detection and sorting asset. This helps to guarantee the accuracy of the parts produced by the machine. CP-45FV NEO also features a self-diagnosis model which is capable of detecting potential errors and recommending corrective action. Overall, CP45FV NEO is an advanced, reliable and highly efficient PC board assembly and manufacturing equipment. It offers a streamlined design and automated processes to increase production speed and yield high-precision parts. The built-in safety, quality control and maintenance features make SAMSUNG CP-45FV NEO ideal for high-volume production.

There are no reviews yet