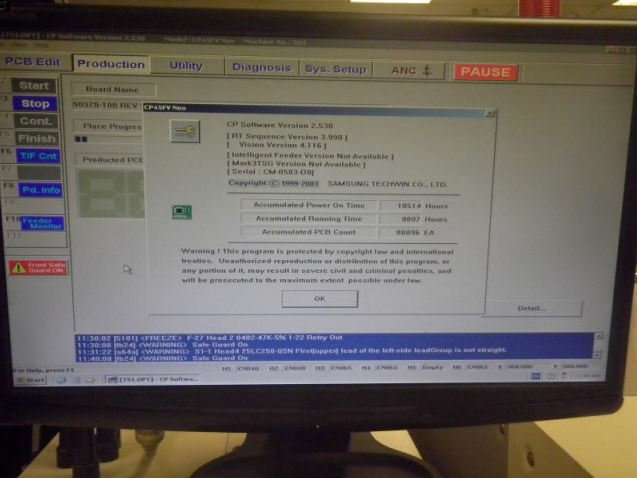

Used SAMSUNG CP-45FV NEO #9086073 for sale

URL successfully copied!

Tap to zoom

ID: 9086073

Vintage: 2003

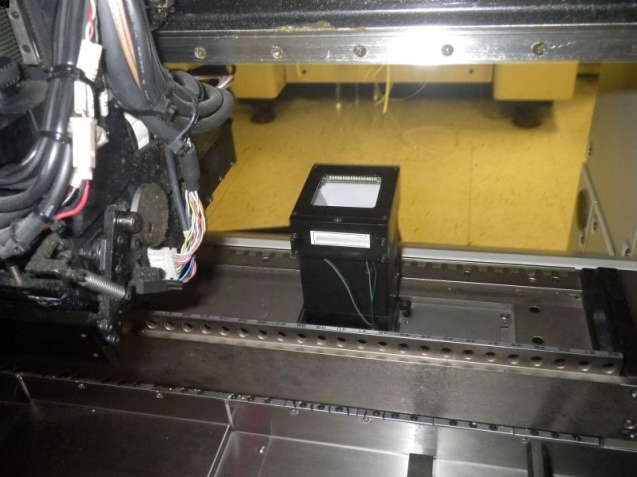

Pick and place machine

Vision system

Upward camera for larger components

Placement: 18,274 CPH

Component range: 0201 to Sq 55 mm

Board size range: 50mm x 30mm to 460mm x 400mm

Digital illumination system: (16 light levels)

Feeder slots: 104 (8 mm)

Hours: 17,731

2003 vintage.

SAMSUNG CP-45FV NEO is a PC board assembly and manufacturing equipment designed for the prototyping and small-scale production of printed circuit board (PCB) assemblies. This advanced piece of equipment features an expandable modular design that allows it to be adapted to a wide variety of process requirements. It provides complete manufacturing solutions for everything from simple prototypes to high-volume production runs. SAMSUNG CP45FV NEO is equipped with precision production components such as a high-speed multi-function head, a vision system, and machine vision. This combination of components allows for fast and accurate placement of components onto the PCBs. A specialized print-head is also equipped with the unit to accurately deposit solder paste onto the PCB. Additionally, CP-45FV NEO provides flexible setup and options for a wide range of component types, from Tall and Wide parts, to BGA components, QFPs, and more. The machine provides high accuracy on component placement and ensures a consistent process throughout the production process. It is also designed for minimal lead times, with high-speed spindle speeds that can provide up to 25,000 cph placements. The machine's high accuracy also minimizes component-compromised and solder-skipped PCBs, allowing for higher yields and reduced cycle times. This feature also helps to both reduce and optimize costs, leading to fewer defects. CP45FV NEO also offers a number of capabilities to help improve the quality of the finished product. These include comprehensive fault diagnostics, vision data logging, and automated process tracking. Additionally, the machine offers a variety of different options for integration into existing production lines, including both manual and automated transfer systems. This helps to optimize the entire process, from PCB production to assembly. Overall, SAMSUNG CP-45FV NEO is an exceptionally advanced and reliable PC board assembly and manufacturing tool. With its precision components, flexible setup, integrated fault diagnostics and process tracking, and wide range of options for integration, it provides users with a comprehensive solution for PCB prototyping and production. It is also an excellent solution for high-volume production runs, providing detailed process monitoring and improved yields and cycle times. This makes it an ideal choice for any production environment.

There are no reviews yet