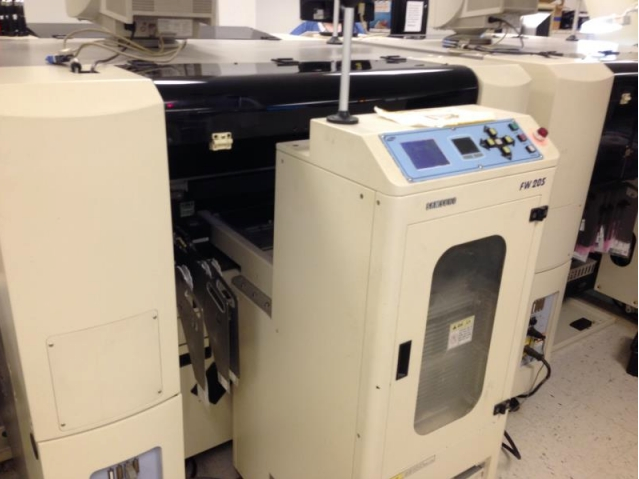

Used SAMSUNG CP-45FV NEO #9086075 for sale

URL successfully copied!

Tap to zoom

ID: 9086075

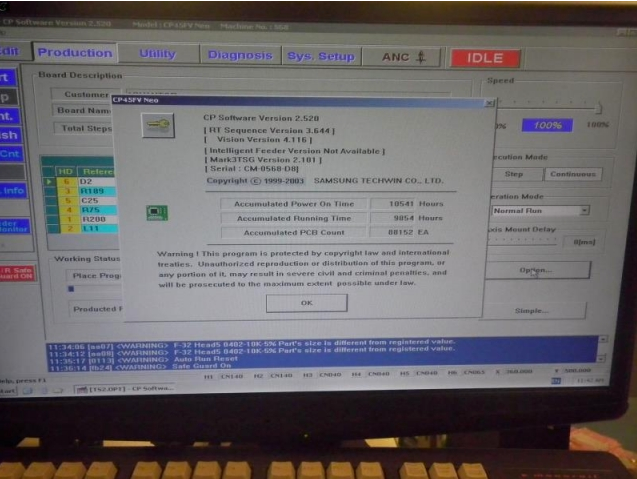

Vintage: 2003

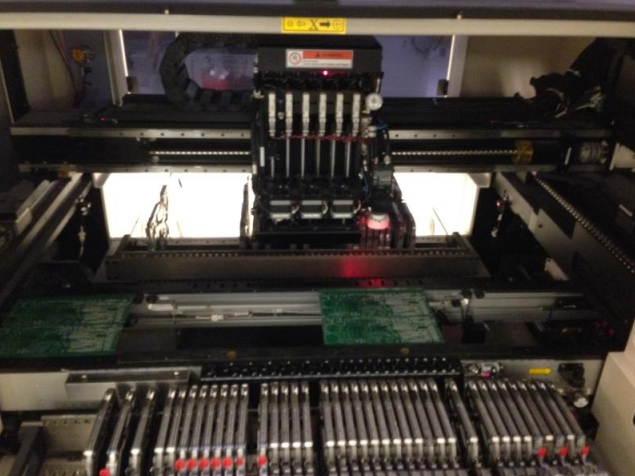

Pick and place machine

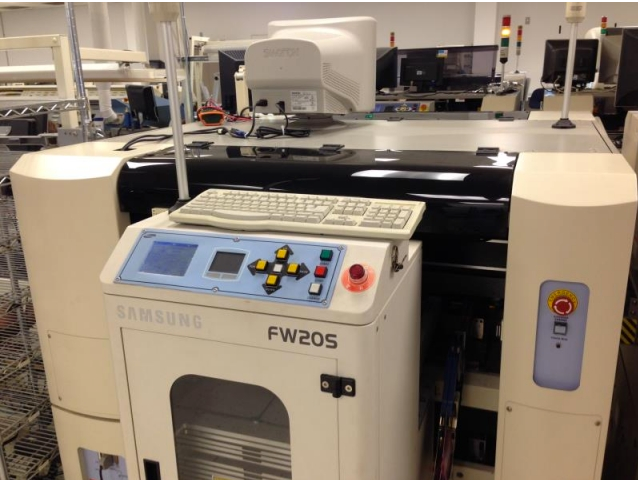

Tray changer (model FW20S)

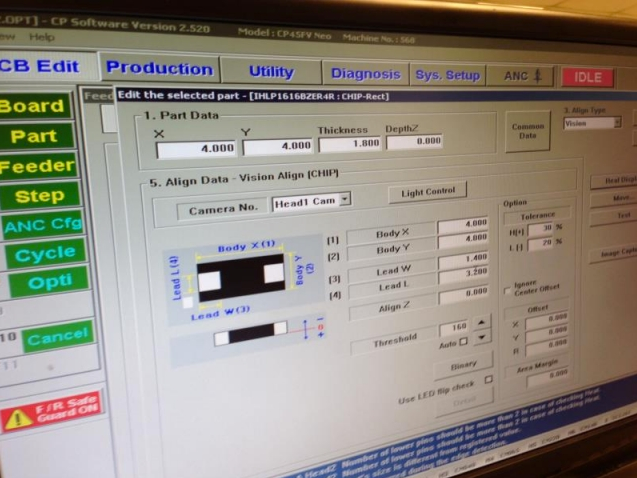

Vision system

Upward Camera for larger components

Placement: 18,274 CPH

Component range: 0201 to Sq 55 mm

Board size range: 50mm x 30mm to 460mm x 400mm

Digital Illumination System (16 light levels)

Feeder slots: 104 (8 mm)

Hours: 17,658

2003 vintage.

SAMSUNG CP-45FV NEO is a high-performance PC Board Assembly and Manufacturing equipment designed for the precision placement of components onto printed circuit boards (PCBs). The system provides an accurate, streamlined, and efficient manufacturing process, resulting in minimized production time and costs. With its advanced vision unit and height-based camera technologies, the machine is able to accurately recognize and place components of different sizes and shapes up to 0.3 mm high onto the PCB. SAMSUNG CP45FV NEO features an industry-leading placement head that has been specifically designed for the accurate placement of components. The tool includes a high-powered, eight-position placement head, and the total component placement area is 4,480 x 4,480 mm. This head is also designed for high-performance placement accuracy, and has the ability to place components up to 0.3 mm high and 0.3 mm wide. It is also equipped with an advanced vision asset that checks for component alignment prior to placement, so that the accuracy of the end product is maximized. Additionally, the model's height-based camera technology provides an extra layer of accuracy and detail when identifying components for placement. The equipment also includes an array of feeder technologies designed to provide a fully automated process for component loading. CP-45FV NEO includes an oscillation feeder with a total of 16 feeders that can be simultaneously used, allowing for the automatic loading of different component sizes and shapes. Additionally, the system can also be configured with a barcode reader to keep track of components, providing an extra layer of accuracy in component tracking and recognition. CP45FV NEO also includes a range of features to provide a complete production solution. It has a fully automated Optical Inspection unit designed to perform quality control on all components placed, and the machine has the capability to detect any misalignment or faulty components to ensure a quality end product. Additionally, the tool is also configured with a dedicated production traceability software that can be integrated with different systems to store and provide data on production process parameters and history. Overall, SAMSUNG CP-45FV NEO is a reliable, high performance, and efficient PC Board Assembly and Manufacturing asset. It is equipped with a variety of features and technologies that ensure precise component placement, and is designed for minimal production time and costs. The model's automation capabilities, advanced vision equipment, and height-based camera technologies make it the ideal choice for those who need to ensure maximum accuracy in component placement on PCBs.

There are no reviews yet