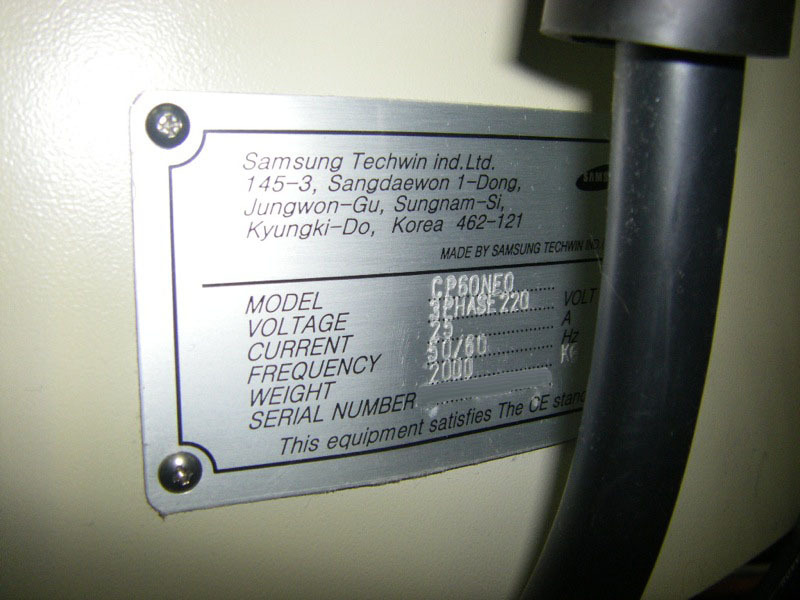

Used SAMSUNG CP-60 NEO #200371 for sale

URL successfully copied!

Tap to zoom

SAMSUNG CP-60 NEO is a highly advanced PC board assembly and manufacturing equipment. It is designed to enhance the efficiency and production time of the board assembly processes. It provides an excellent tracking system and higher accuracy rates than traditional, manually operated systems. CP-60 NEO consists of an integrated digital control unit, a processing unit, and a human-machine interface (HMI). The digital control machine is responsible for controlling the entire manufacturing process, from assembly to material handling. This control tool is extremely easy to use and highly customizable. It can be programmed and operated from the user-friendly HMI. The processing unit of SAMSUNG CP-60 NEO utilizes high-speed digital signal processors (DSP) for the various assembly operations. The DSPs are designed to provide a high degree of accuracy and repeatability to ensure the highest quality products. It also allows for process control and real-time data collection when necessary. The human-machine interface of CP-60 NEO is designed to allow operators to manage and control the entire manufacturing process. It utilizes a touch-screen display and simple menus, making for ease of use and fast responsiveness. It also offers a wide range of advanced functions such as recipe management, process monitoring, material tracking, and much more. SAMSUNG CP-60 NEO is capable of processing a wide range of substrate types, all of varying sizes. This includes FR4, Metal Core, Edge Plated, and High Layer Count boards. It also features a specialized cutting head to ensure accurate cutting and metering of the materials. Overall, CP-60 NEO is an excellent PC board assembly and manufacturing asset. It is extremely fast, efficient, and accurate, making it the perfect choice for any board assembly and manufacturing process.

There are no reviews yet