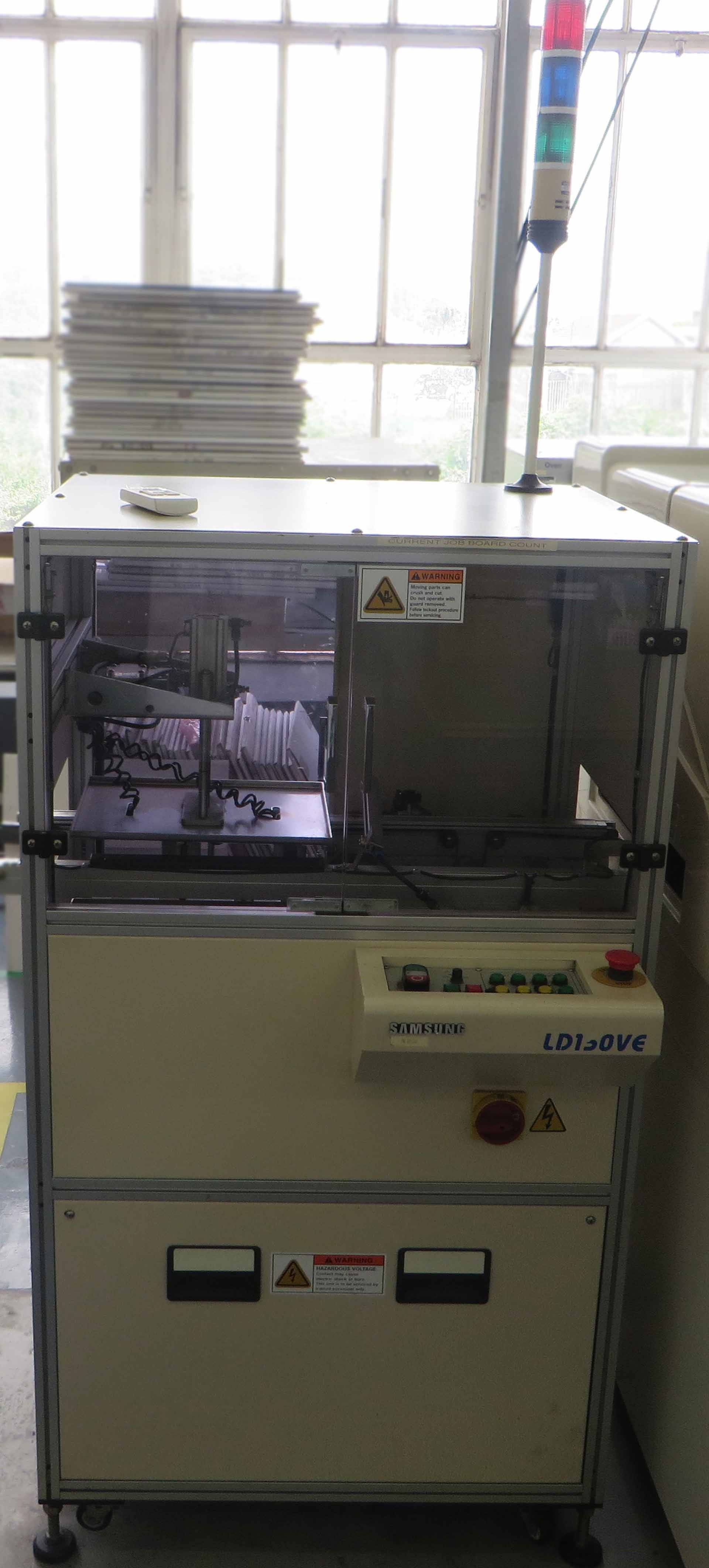

Used SAMSUNG LD15OVE #9206628 for sale

URL successfully copied!

Tap to zoom

SAMSUNG LD15OVE PC Board Assembly and Manufacturing Equipment is a powerful and comprehensive automated manufacturing solution for optimizing board assembly and creation. This system enables the manufacturing of boards with fast, accurate and highly repeatable processes while optimizing the overall cost and time. The unit consists of tools, components and machines which are all integrated into a single platform. The platform is designed to ensure high levels of productivity, reduced cost and improved accuracy. The machine includes an intelligent vision tool, high speed router, hot air pencil, pick and place machines with placement accuracy of ± 0.1 mm, and fully automated routing and drilling machines with matched accuracy of ± 0.05 mm. The integrated platform allows boards to be manufactured with a single operation, allowing faster throughput and improved quality. The vision asset is used to check the board and trace the components for placement and routing, while the router drills and cuts the board. The hot air pencil is used for desoldering and soldering of components. The pick and place machines can place components with maximum speed and accuracy, while the fully automated routing and drilling machines automatically route, drill and cut the board. The model is designed to handle boards with different sizes, varying from 125 x 300 mm to 435 x 330 mm. The fully automated routing and drilling machine has a 12-tool magazine, capable of placing components from 0402 up to 394. The equipment also supports a range of soldering processes, including SMD and conventional soldering, tin-lead plating, oven-baking, reflow soldering and infra-red soldering. LD15OVE PC Board Assembly and Manufacturing System also supports different types of inspection and testing systems to assure the highest level of accuracy. Overall, SAMSUNG LD15OVE PC Board Assembly and Manufacturing Unit is an ideal solution for companies looking to optimize their board assembly and manufacturing process. It offers quick cycle times, maximum accuracy and repeatability, as well as cost reductions. The machine combines advanced technologies such as intelligent vision inspection, high speed routers, hot air pencils, pick and place machines and more. It allows your production process to be faster, more efficient and of higher quality.

There are no reviews yet