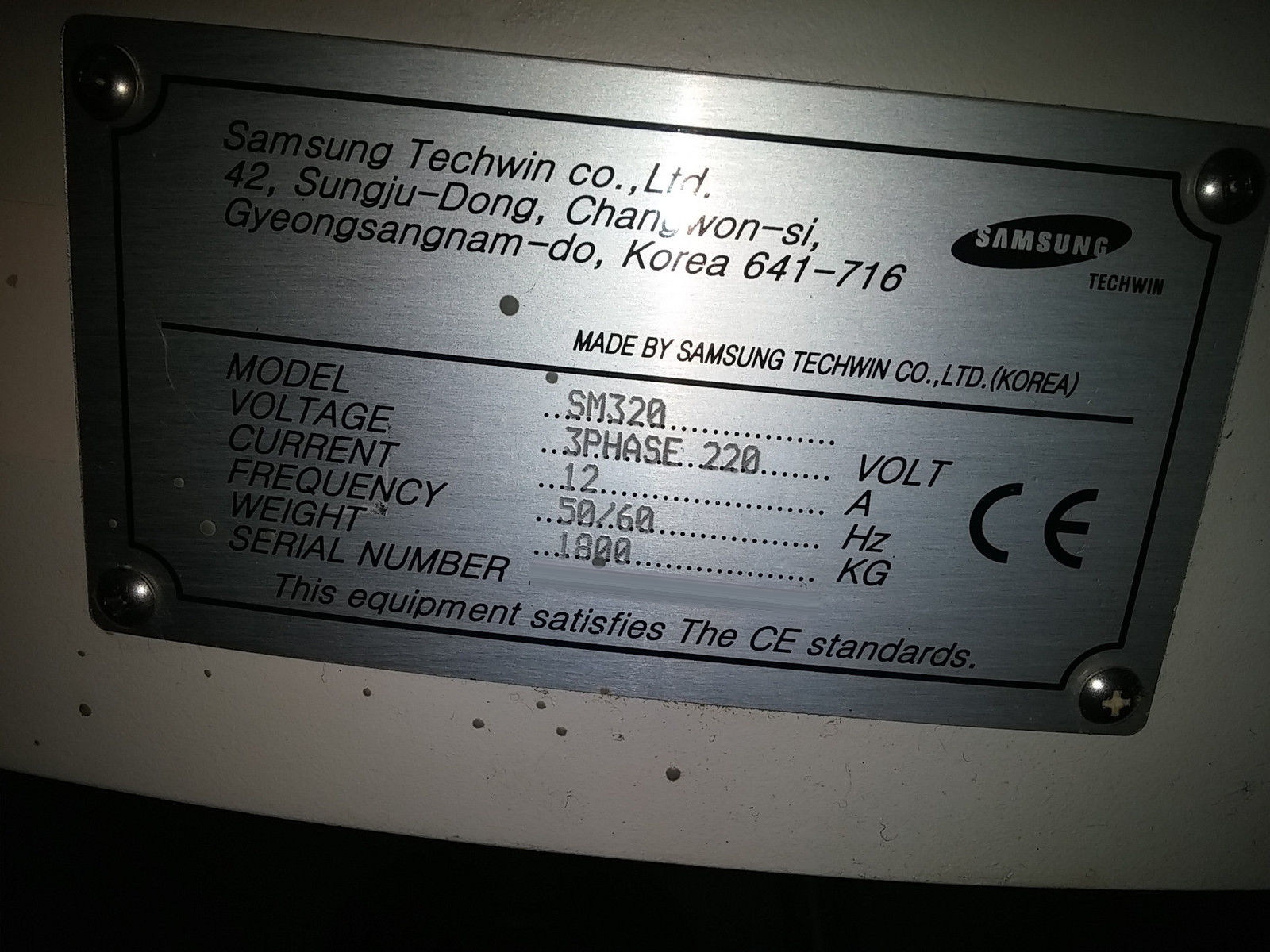

Used SAMSUNG SM-320 #9101909 for sale

URL successfully copied!

Tap to zoom

ID: 9101909

Vintage: 2007

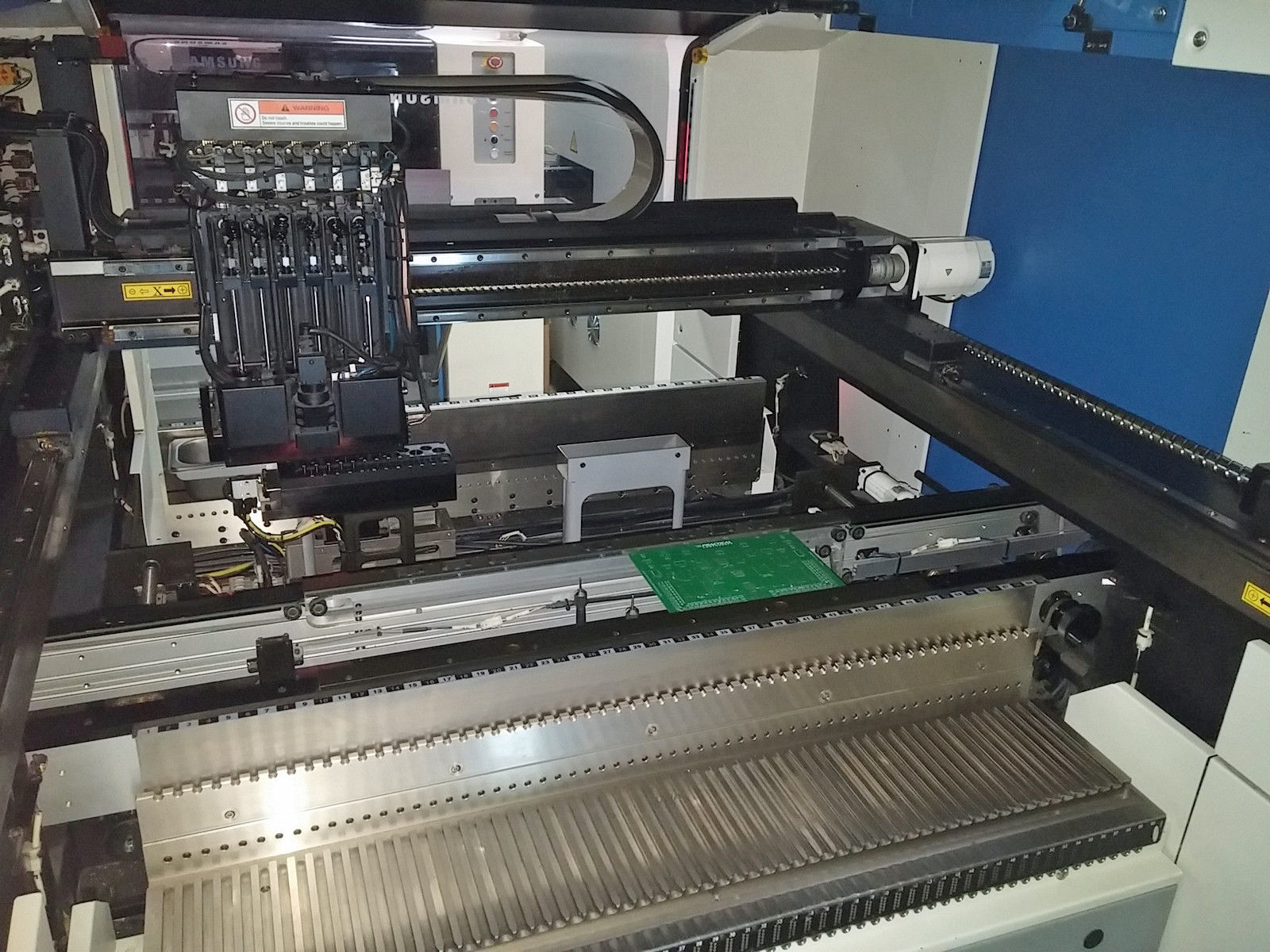

6-Head pick and place machine

Fixed banks

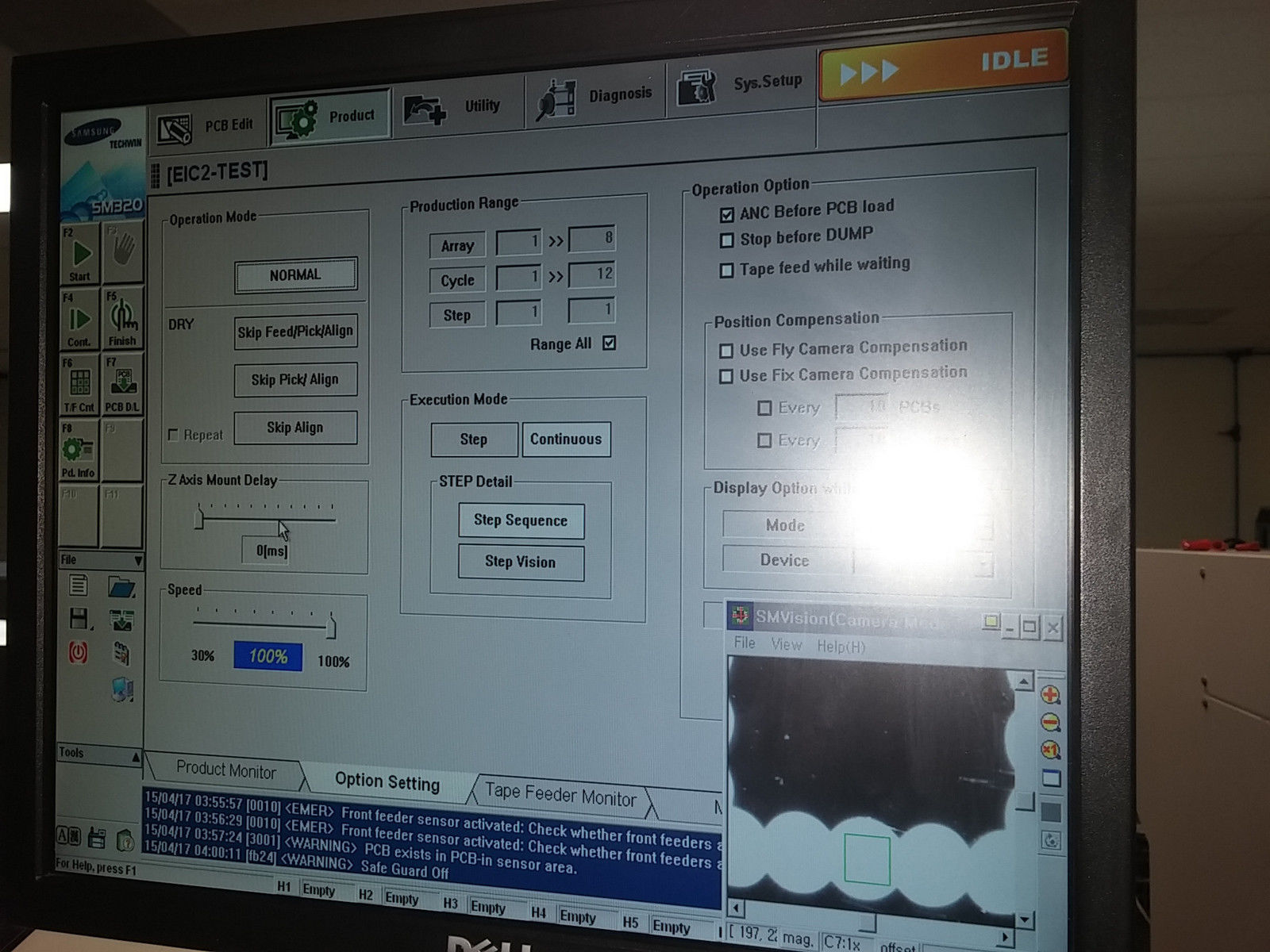

“On the fly” vertical alignment system aligns components from the bottom without traveling to a stationary alignment area

IPC 9850 placement speeds: up to 18,500 CPH

Upward vision camera system for fine pitch components (15mils) and BGA ball inspection

Places from 0201 up to 55mm square components

Connector placement: up to 72mm long

Placement accuracy: %0.03mm @3 sigma

(2) Modified feeder bases and Docking Feeder Carts

Maximum feeder capacity: (112) 8mm tape feeders

3-Stage transport system

36-Pocket Auto Nozzle Changer

2007 vintage.

SAMSUNG SM-320 is a highly advanced, multi-functional, PC board assembly and manufacturing equipment designed to meet the fast-paced production needs of modern businesses. It is equipped with a range of advanced features to enable efficient assembly of high-quality and reliable printed circuit board (PCB) products in large volumes. SAMSUNG SM 320 has the capabilities to perform effective, automated pick-and-place operations with precise accuracy and speed. This is made possible with the advanced, high-performance camera and vision system it is equipped with. The vision unit is capable of picking up the slightest changes in the product's shape or size, which ensures precise placement of the components for fast and consistent performance. SM-320 is integrated with the EZ-Diagnosis technology, which is a remote machine for diagnosing and repairing any line issues. This technology has the capability to identify malfunctioning boards and then replace them with a functional board for quick and easy repair. In addition, SM 320 has a comprehensive placement attempt tool which works hand-in-hand with the vision asset to ensure that it can retry and precisely place the components on the board. SAMSUNG SM-320 also comes with a built-in Optimal Component Placement Model (OCPS) which helps to adjust the component placement to a dimensional layout that is optimized for high-speed assembly. The OCPS is equipped with four major algorithms to determine the best component placement for the highest productivity. Furthermore, SAMSUNG SM 320 is designed with a flexible CC-map which helps to customize component maps that meet the exact requirements of the product's circuit boards. Finally, SM-320 has the ability to self-learn and adjust on shift changes for improved precision. It also features a pause-and-resume function which enables it to stop part production for a certain length of time and then resume production for an extraordinary high level of consistency and speed. Overall, SM 320 is a reliable, efficient, and highly advanced PCB assembly and manufacturing equipment that produces consistent and high-quality PCB products in large quantities. It's comprehensive technology and advanced features make it the perfect choice for any modern business looking to maximize production and quality.

There are no reviews yet