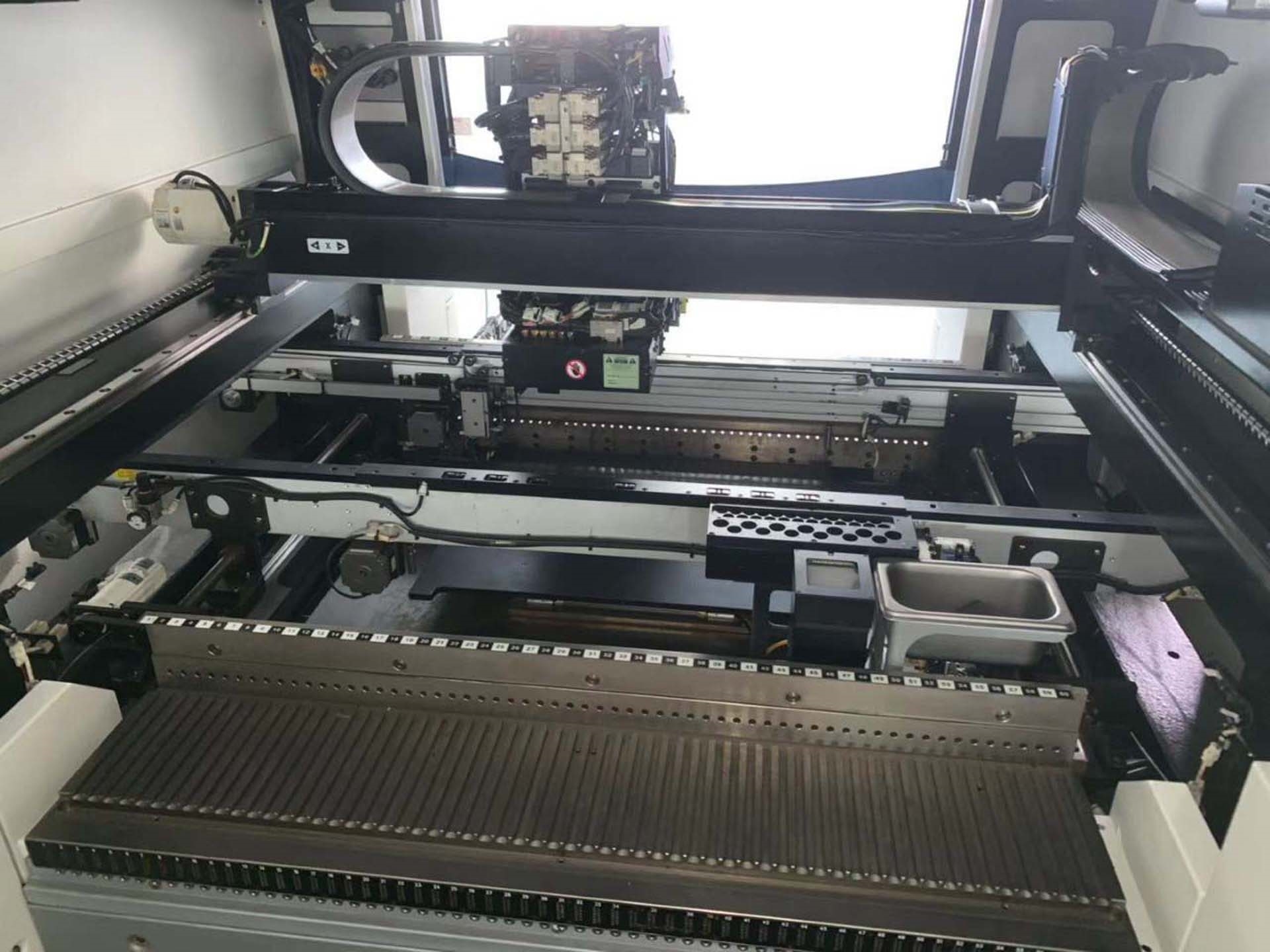

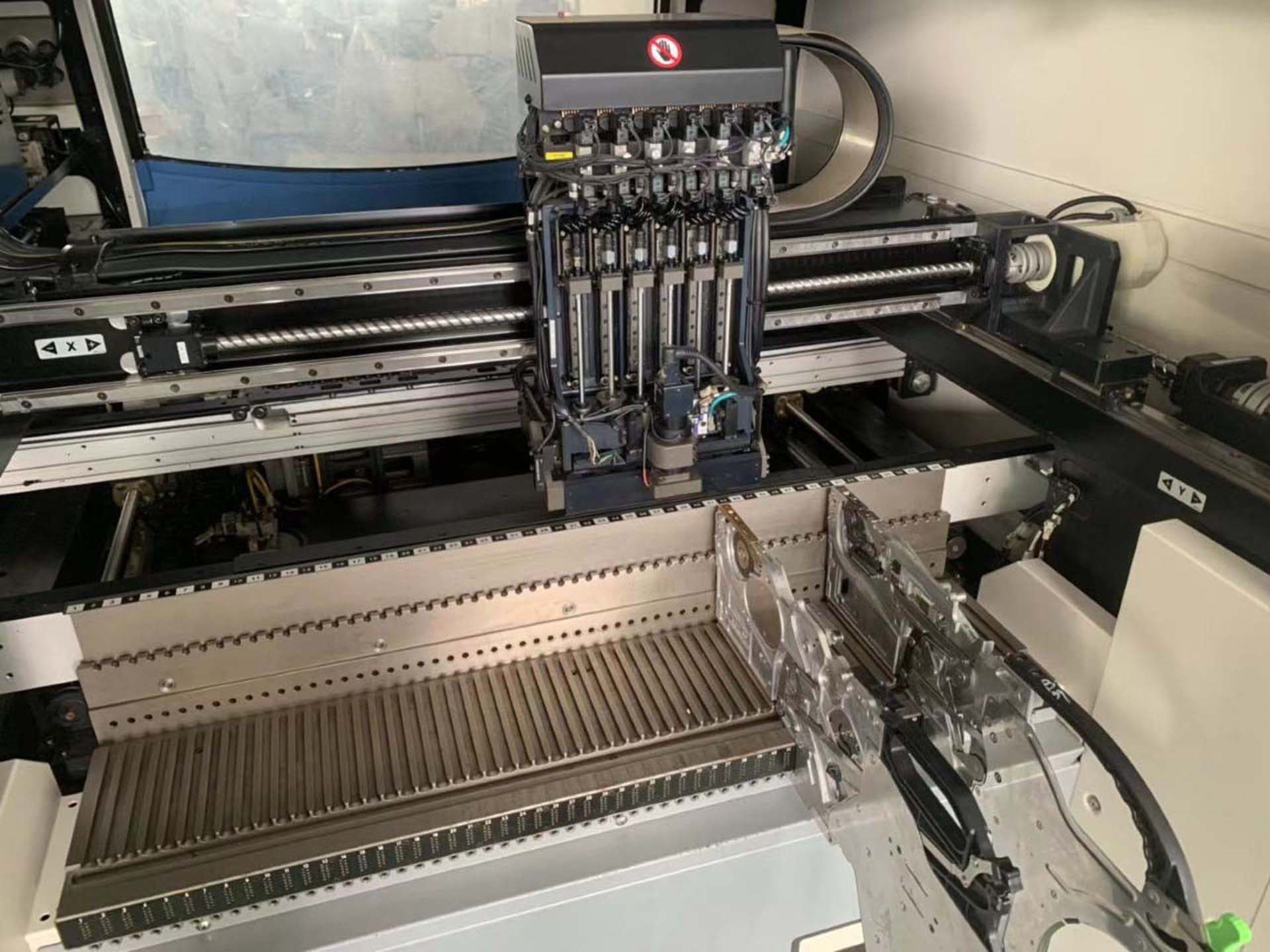

Used SAMSUNG SM-421 #9250965 for sale

URL successfully copied!

Tap to zoom

SAMSUNG SM-421 is a PC board assembly and manufacturing equipment that is incredibly versatile and cost-effective. It is a fully automated, multi-stage, multi-function system that provides a range of solutions to meet your manufacturing requirements. This includes high speed placement, flexible component recognition and quick changeover. This unit allows for highly precise component placement, with the ability to accurately mount components with up to 0.4 mm pitch, and with combined vision solutions that ensure high quality placements. SAMSUNG SM421 also boasts extensive component capability, including support for a range of packages, from SOIC on up to BGA and 01005s, as well as many irregularly shaped components. This machine is able to hold components in place up to 0.03-inch thickness and support 15g (0.32 oz) or lighter placement by using its sophisticated vision tool. Moreover, SM 421 is equipped with a modular nozzle configuration that enables simultaneously placement of multiple components. Its unique robotic arm allows for quick changeover for a wide range of components and board types, eliminating costly downtime due to format changes. The arm also offers efficient real-time programming, allowing the asset to respond quickly to change requests from the factory floor. In addition, SAMSUNG SM 421 contains a ballooning solution that minimizes production errors and improves production management by ensuring accurate and efficient inspection of packages on the manufacturing line. This model is also highly flexible, providing a simple and effective user interface and a number of additional features that can be integrated for improved usability. Overall, SM-421 is an advanced multi-function PC board assembly and manufacturing equipment that is highly reliable and cost-effective. It has a range of highly accurate and reliable placement capabilities, a unique robotic arm for quick changeover, and a clever ballooning solution to minimize production errors. This system is capable of handling a variety of components, packages and board types and is great for a wide range of production requirements.

There are no reviews yet