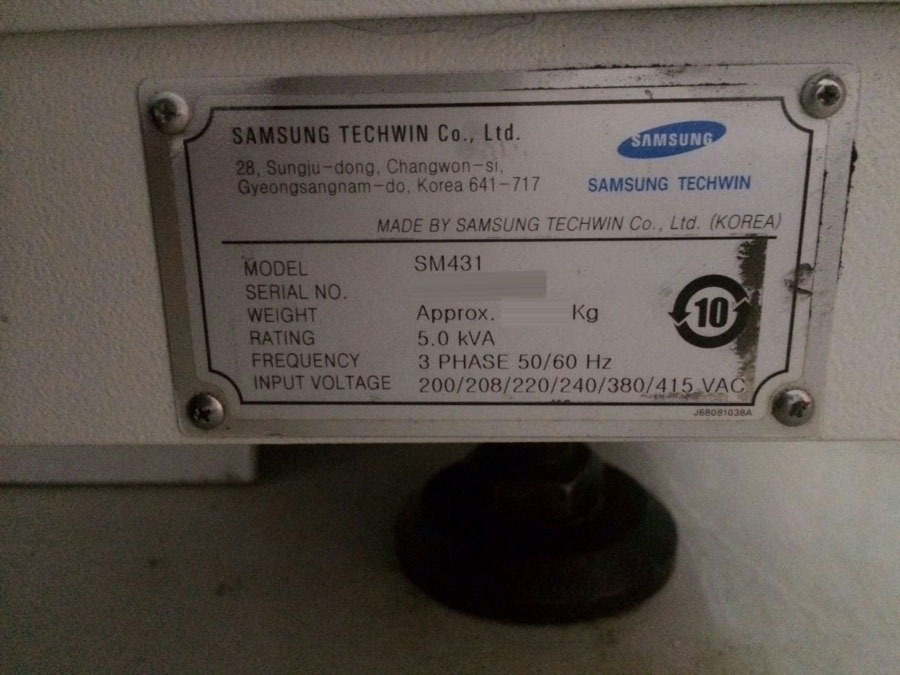

Used SAMSUNG SM-431 #9077409 for sale

URL successfully copied!

Tap to zoom

SAMSUNG SM-431 is an advanced PC board assembly and manufacturing equipment designed for high-volume operations. It is a fully automated, modular system designed for flexibility and optimized performance. It is equipped with a four-sided conveyor belt loop that transports the PCB through the various stages of assembly. To ensure accuracy and precision, SM-431 features advanced vision technology and a wide range of mounting systems. It offers a range of component placement capabilities for both through-hole and surface-mount technology, utilizing either manual or automated placement. The unit includes a multilane handling machine, allowing multiple lanes of boards to be fed into the tool. It is further equipped with a 3D AOI asset to detect any defects in the board assembly. SAMSUNG SM-431 model offers four separate process stations, each capable of handling up to five component feeders and up to three component placement heads. Each process station is equipped with Placement Checking Equipment (PCS) software to ensure proper component placement. For added flexibility, SM-431 also offers a fifth process station which supports secondary component placement. The board is passed through a select type of soldering system depending on component size and board size, offering flux-free soldering, convection soldering and dip soldering. Temperature profiling is also available for more accurate soldering results. Finally, the automated data capture feature and on-board diagnostics allow for rapid detection and repair of any errors. SAMSUNG SM-431 is truly a state-of-the-art unit for assembly and manufacturing of PC boards. It is designed for ultra-high-volume production with minimum operator intervention and maximum automation. It provides efficient component placement, reliable soldering operations and accurate data capture - all while maintaining exceptional levels of throughput, accuracy and cost-efficiency.

There are no reviews yet